Laser processing device and laser processing method

A laser processing method and laser processing technology, applied in positioning devices, laser welding equipment, metal processing equipment, etc., can solve the problems of processing position deviation, difficulty in precise processing, and wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

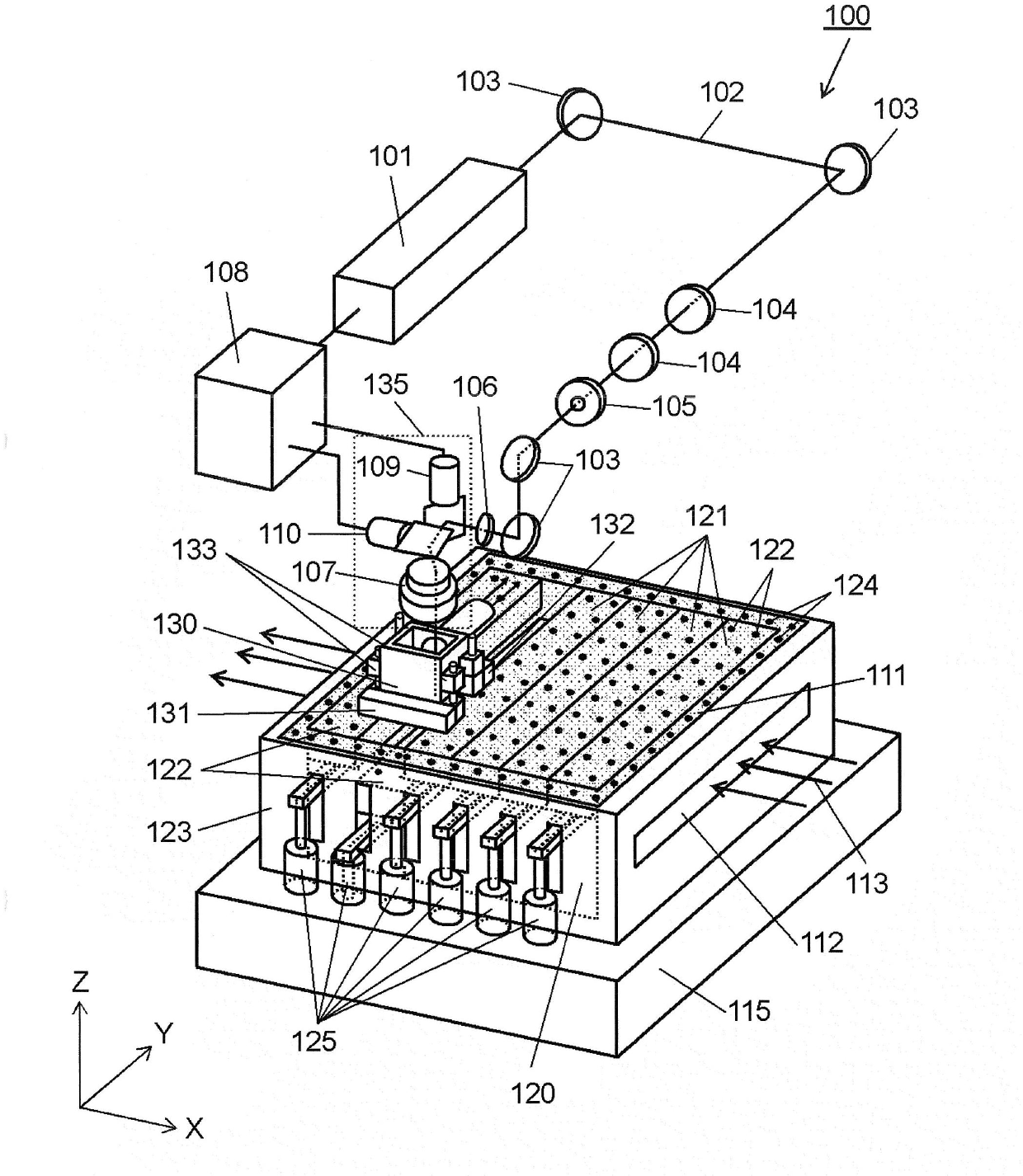

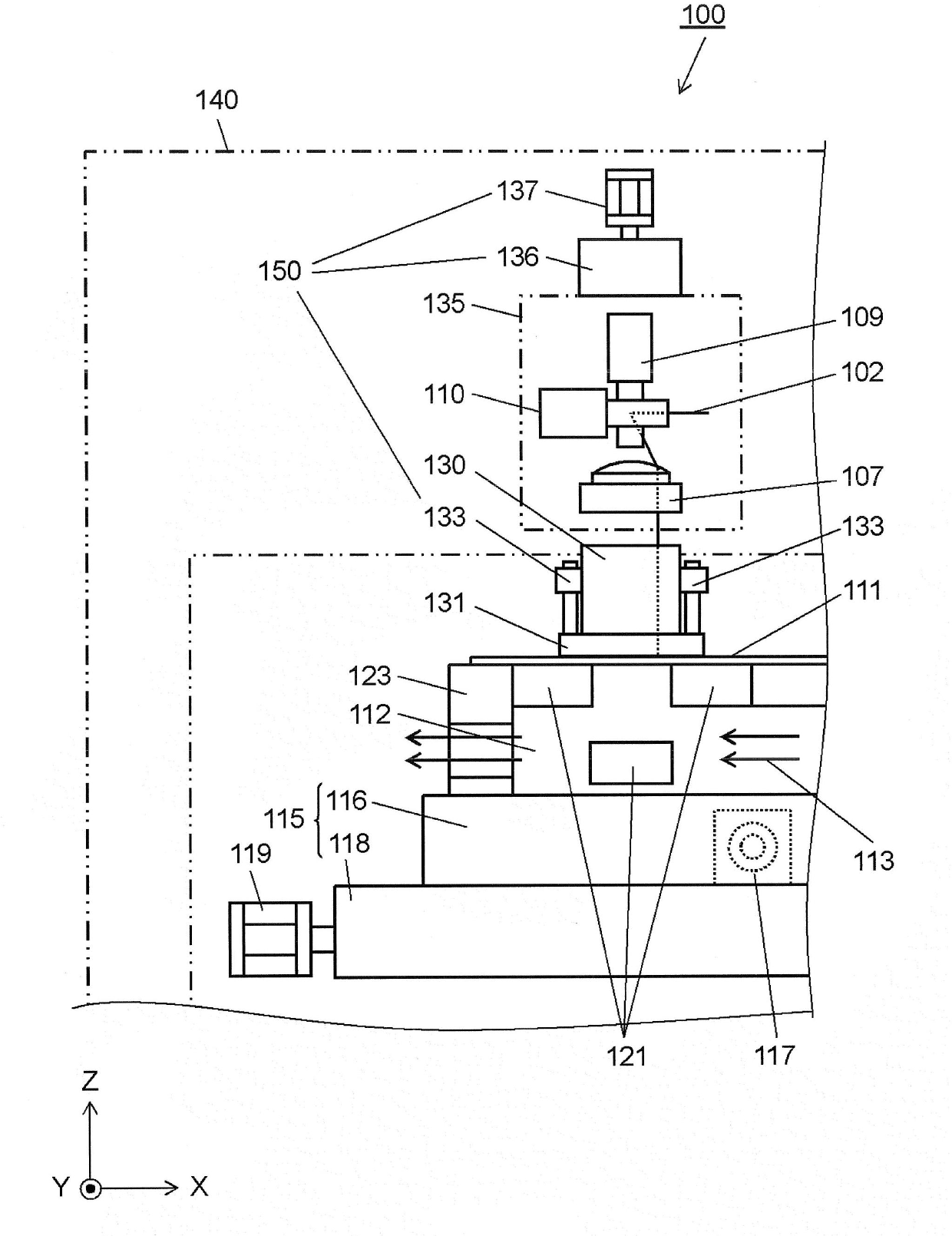

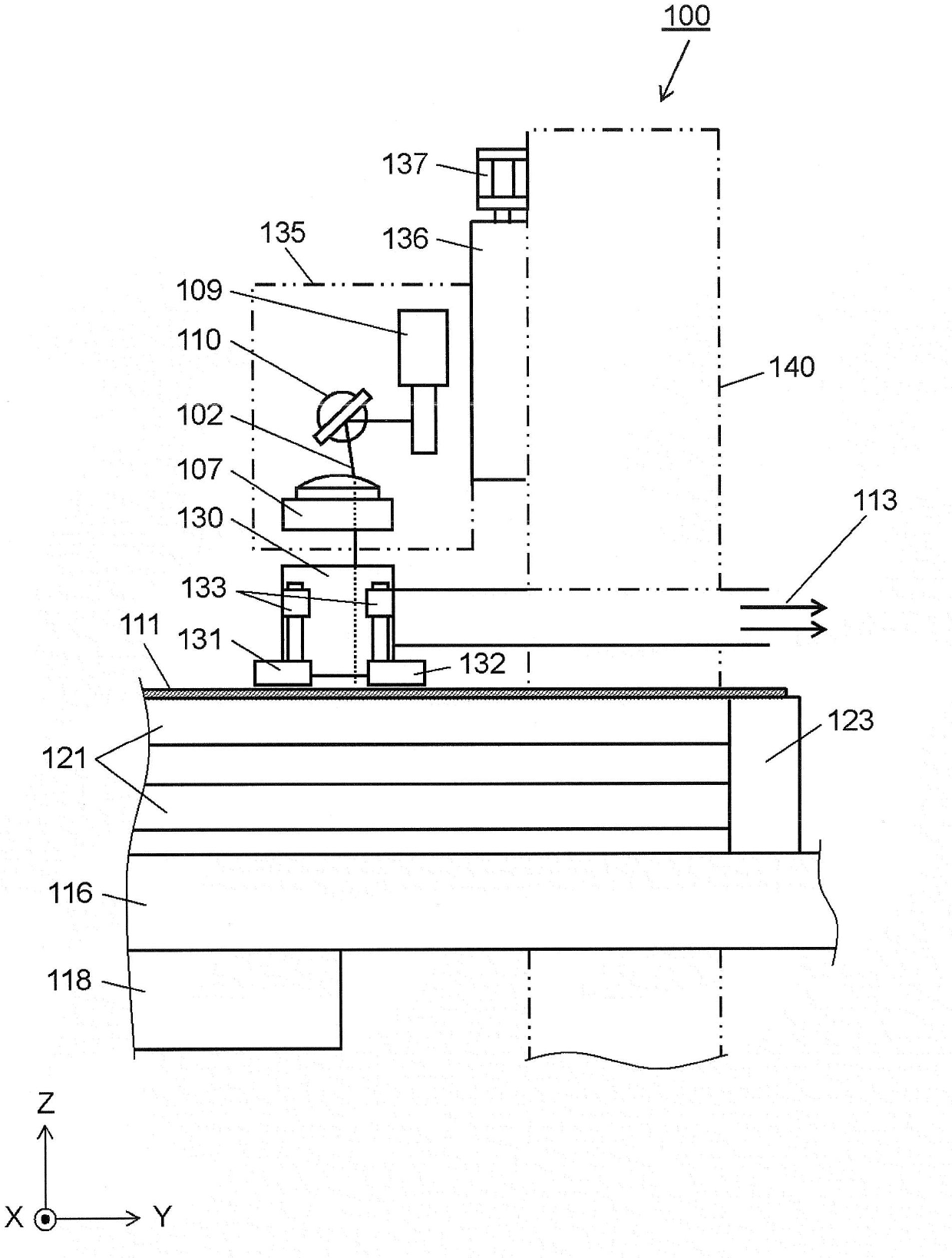

[0048] figure 1 It is a perspective view which shows the schematic structure of the laser processing apparatus 100 which concerns on an example of Embodiment 1 of this invention. figure 2 is a side view when viewing the laser processing device 100 from the Y direction, image 3 It is a side view seen from the X direction similarly.

[0049] Such as figure 1 As shown, a laser oscillator 101 internally oscillates laser light to emit laser light 102 . The emitted laser beam 102 changes its traveling direction by the mirror 103 . A collimator lens 104 for adjusting the beam diameter of the laser beam 102 is arranged in the advancing direction of the laser beam 102 whose advancing direction has been changed by the reflecting mirror 103 . A mask 105 for shaping the beam shape of the laser beam 102 passing through the collimator lens 104 and an aperture 106 for suppressing stray light of the laser beam 102 passing through the mask 105 are also disposed.

[0050] The laser lig...

Embodiment approach 2

[0110] Next, a different example of the processing method using the laser processing apparatus 100 of the present invention will be described. figure 1 , figure 2 and image 3 The structure of the laser processing apparatus 100 shown is the same as that of Embodiment 1 mentioned above. Similarly, a pair of upper surface adsorption devices 131 and 132 and an upper surface adsorption device elevating cylinder 133 for moving the upper surface adsorption devices 131 and 132 up and down are attached to the upper dust collecting device 130 . In Embodiment 2, an air cylinder is used as the upper surface adsorption device elevating cylinder 133, so that each of the upper surface adsorption devices 131, 132 can be independently moved up and down.

[0111] Figure 8A , Figure 8B , Figure 9A to Figure 9C It is a layout diagram showing an example of the setting of the processing area of the workpiece 111 according to Embodiment 2 of the present invention. Figure 9A , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com