Wood burr thorough removing method

A burr and wood technology, which is used in wood processing appliances, machine tools suitable for grinding the edges of workpieces, grinders, etc., can solve the problems of difficult to penetrate burrs, destroy the surface wood fiber structure, and difficult to lay dust, and achieve smoothness and smoothness. The effect of good flatness, reduction of processing defects, and complete removal of burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

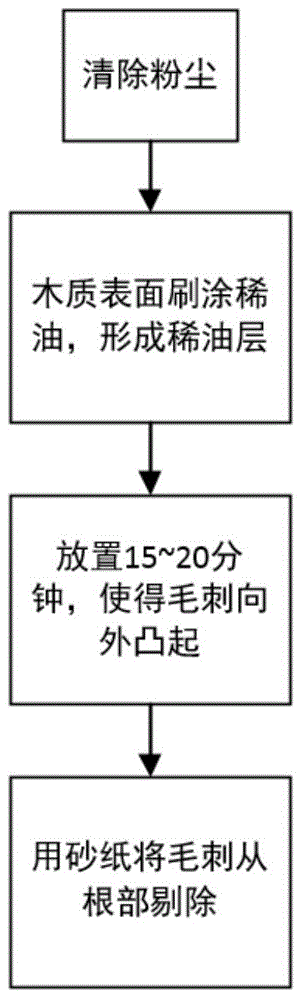

[0026] Examples, see figure 1 In the method for punching through burrs in wood provided by the embodiments of the present invention, after the logs are sawed into boards, or drilled, or grooved by a milling cutter, a large number of burrs will be generated on the board surface or edges, holes or grooves, and then used Brush a layer of thin oil on the wooden surface and sand it with sandpaper, including the following steps:

[0027] (1) Remove the dust on the wood surface after sawing, drilling or grooves;

[0028] (2) Brush thin oil with hairbrush in wooden surface in step (1), hole or groove, form one deck thin oil layer;

[0029] (3) Place it for 15 to 20 minutes. During the placement process, the burrs on the wooden surface, holes or grooves protrude outward under the force of the solidification of thin oil, and a layer of solidified thin oil is formed on the burrs and the wooden surface, making the burrs outward away from wooden surfaces, holes or slots;

[0030] (31) W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com