Method for rolling metal wire bars under magnetostatic field auxiliary effect

A technology of metal wire and static magnetic field, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of high deformation resistance of materials, hardening of processing process, complicated process, etc., and achieve the improvement of yield and plastic deformation ability Improvement and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Extrusion and drawing of copper

[0021] An oxygen-free copper billet with a diameter of 18 cm was obtained through a power frequency induction melting furnace and semi-continuous casting as the billet for copper extrusion and drawing in this embodiment.

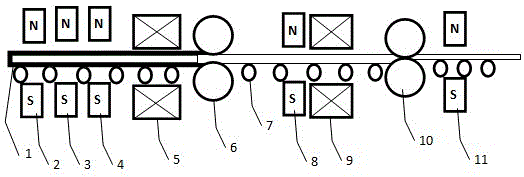

[0022] Continuous extrusion process is used to produce copper wire. The main method steps are as follows: first, the oxygen-free copper billet is heated to 650°C, and then enters the conveying roller table, ready to be sent to the extruder for the first rolling, and then enters the extruder A gradient magnetic field composed of three groups of U-shaped permanent magnets and one group of stable electromagnets is placed on the front conveying roller table; the magnetic induction intensity of the first group of permanent magnets in this embodiment is 0.25T, and the width along the direction of travel of the metal wire rod blank is That is, the width of the action area is 0.5 meters, the magnetic induction i...

Embodiment 2

[0026] Embodiment 2: Extrusion and drawing of copper

[0027] Obtain an oxygen-free copper billet through a power frequency induction melting furnace and semi-continuous casting, and the diameter of the billet is 20 cm, which is used as the billet for copper extrusion and drawing in this embodiment;

[0028] The continuous extrusion and drawing process is used to produce ultra-fine copper wire. The main method steps are as follows: firstly, the oxygen-free copper billet is heated to 650°C, and then enters the conveying roller table, and is ready to be sent to the extruder for the first rolling. A gradient magnetic field composed of three sets of U-shaped permanent magnets and a set of steady electromagnets is placed on the conveying roller table before entering the extruder; the magnetic induction intensity of the first set of permanent magnets in this embodiment is 0.30T, The width of the billet travel direction, that is, the width of the action area is 0.5 meters, the magnet...

Embodiment 3

[0032] Extrusion of embodiment 3 magnesium alloy bar

[0033] Preheat the deformed magnesium alloy ingot with a diameter of 200mm to 350°C and put it into the conveying roller table equipped with a static magnetic field, preheat the extrusion die to 350°C, and use a metal extruder to extrude the magnesium alloy ingot into a 10mm For rods, the corresponding extrusion temperature is 380°C, the extrusion rate is 0.5m / min, and the extrusion ratios of the two passes are 10:1 and 2:1 respectively; the static magnetic field installed in the first pass is A gradient magnetic field composed of three sets of circular permanent magnets and a set of stable electromagnets arranged side by side: the magnetic induction intensity of the first set of permanent magnets is 0.20T, and the width along the direction of travel of the metal wire bar blank, that is, the width of the action area is 0.20 meters, the magnetic induction intensity of the second group of permanent magnets is 0.40T, the widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com