Inner decoration piece fixing device

A technology for fixing devices and interior parts, applied in auxiliary devices, vehicle parts, transportation and packaging, etc., can solve the problems of poor stability, welding flashes, cracks, arc craters, and reduced product qualification rate with bare hands, and avoid welding. Defects, enhance stability, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

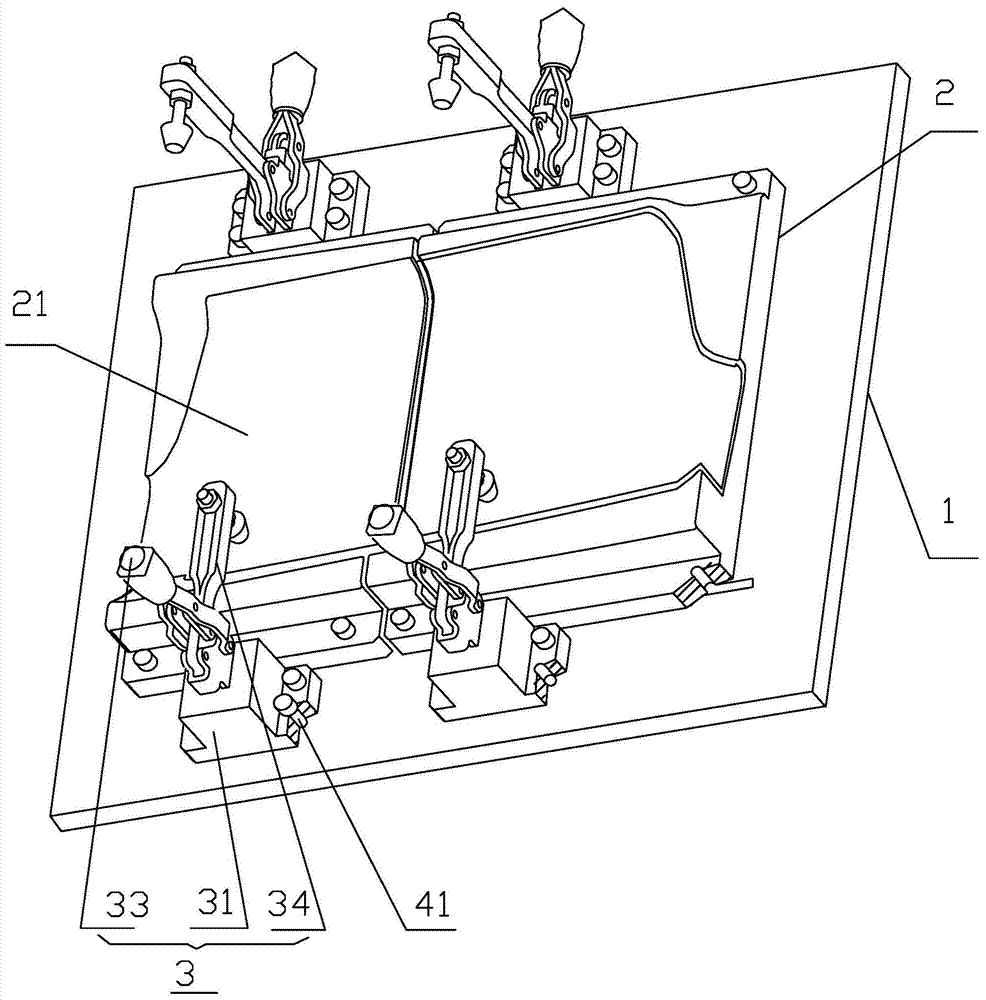

[0025] Such as Figure 1-3 As shown, the interior trim fixing device includes a pallet 1 and two interior trim brackets 2. Each interior trim bracket 2 corresponds to two pressing devices 3, and the pressing devices 3 are respectively arranged on both sides of the interior trim bracket 2.

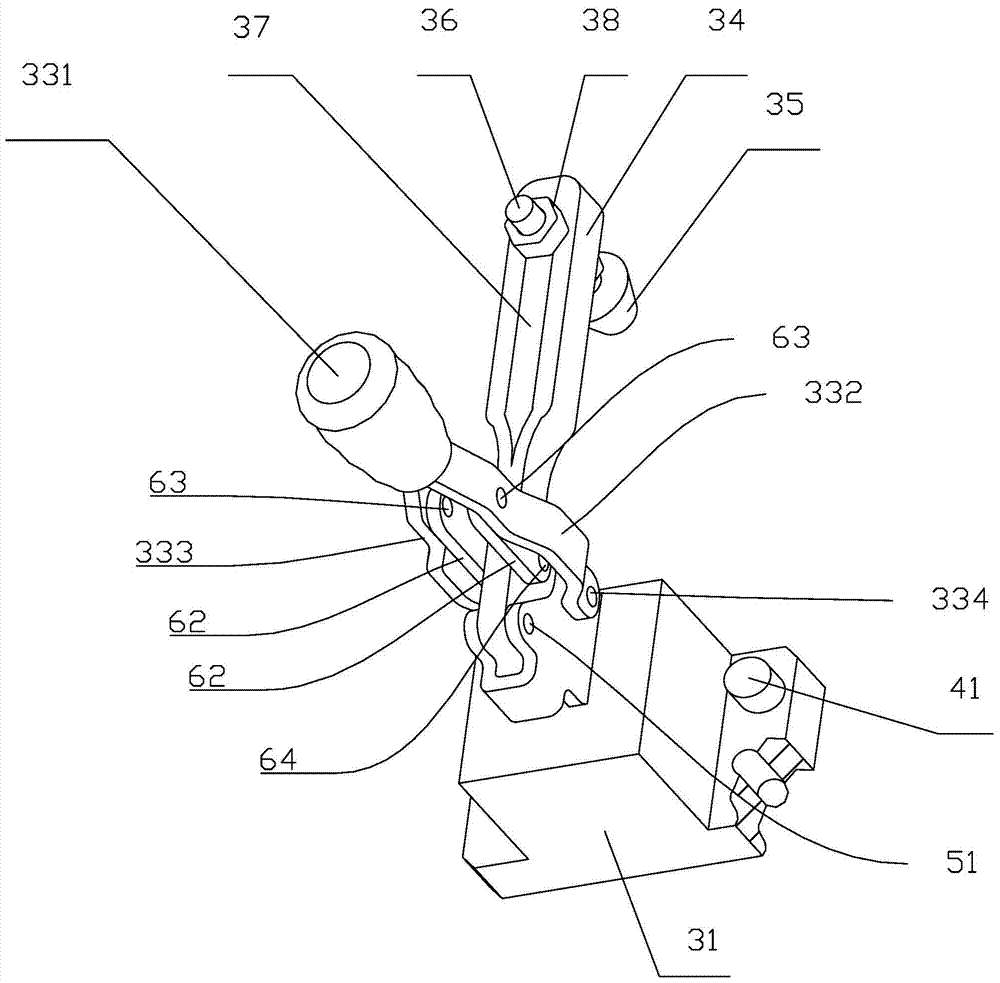

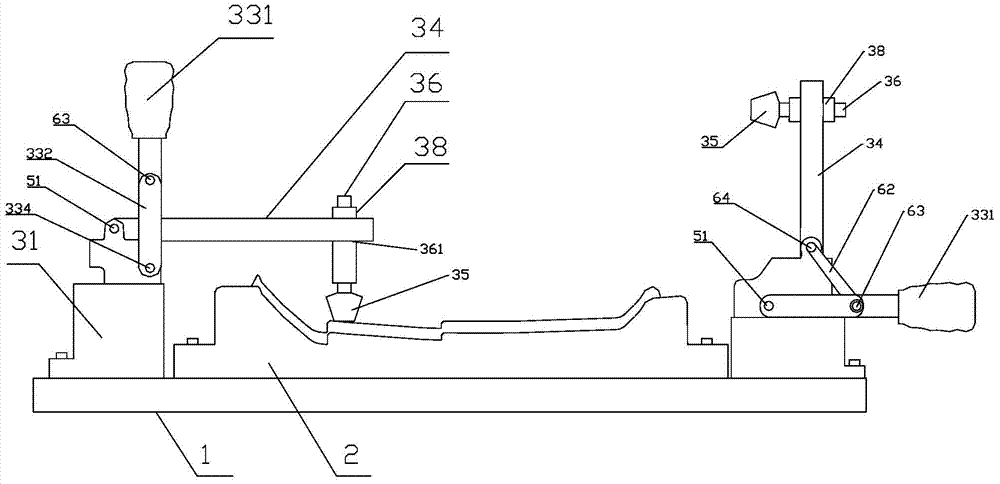

[0026] The pressing device 3 includes a base 31, a pressing head 32 and a handle 33. The base 31 is detachably arranged on the pallet 1 by the first bolt 41. The pressing head 32 includes a connecting rod 34, a pressing block 35 and an adapter rod 36. One end of the connecting rod 34 is rotatably mounted on the base 31 via the first pin 51, and a pressing block 35 is mounted on the other end. The connecting rod 34 is provided with a bar-shaped through hole 37. A step 361 is provided on the adapter rod 36. One end of the adapter rod 36 passes through the bar-shaped through hole 37, and the end is provided with a thread. The step 361 abuts against the lower surface of the connecting rod 34...

Embodiment 2

[0031] The difference between this embodiment and the first embodiment lies in the structure of the pressing device 3. Such as figure 2 As shown, the pressing device 3 includes a base 31, a pressing head 32 and a handle 33. The base 31 is detachably arranged on the pallet 1 by the first bolt 41. The pressing head 32 includes a connecting rod 34, a pressing block 35 and an adapter rod 36. One end of the connecting rod 34 is rotatably connected with the handle 33 through the fifth pin shaft 52. A pressing block 35 is installed at the other end. The connecting rod 34 is provided with a bar-shaped through hole 37. A step 361 is provided on the adapter rod 36. One end of the adapter rod 36 passes through the bar-shaped through hole 37, and the end is provided with a thread. The step 361 abuts against the lower surface of the connecting rod 34. A nut 38 is installed at the end of the adapter rod 36. The nut 38 abuts on the upper surface of the connecting rod 34. The connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com