Welding process of longitudinal seam of blast furnace shell

A welding process and longitudinal welding seam technology, applied in welding equipment, manufacturing tools, edge parts of workpieces, etc., can solve the problems of long welding time, great influence on welding quality skills and physical fitness, and the inability of multiple people to operate at the same time. The effect of labor intensity, beautiful appearance, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A welding process for the longitudinal weld seam of a blast furnace shell, the welding process steps are:

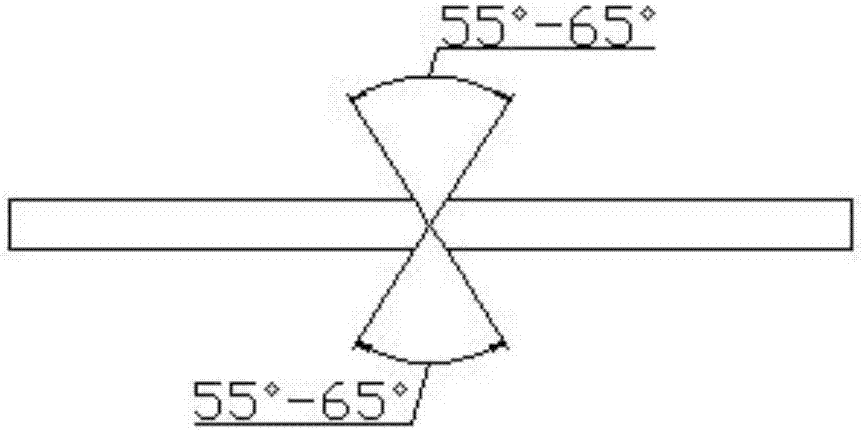

[0035] 1) Preparation of welding equipment

[0036] Adopt HCD500-6 automatic welding machine to adjust various welding parameters (0~1100mm / min) through the track, and clamp the welding torch of the full set of functional equipment for carbon dioxide gas shielded welding on the automatic welding machine, and then pair it well: L left stop / R Right stop / C delay, swing speed, swing angle (adjustment range 0~10°), travel speed (0~1100mm / min), arc closing / non-welding / welding, centering, walking direction, start / stop. Welding speed at various positions, adjust each welding data during normal welding, compare all welding processes with qualified quality, and the combined automatic welding machine finally meets the welding requirements of large and thick plate blast furnace shells.

[0037] The original HCD500-6 automatic welding machine holding welding torch support r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com