Forming and processing method of titanium alloy high-pressure seamless gas cylinder for ships

A technology of seamless gas cylinder and processing method, which is applied in metal processing equipment, applications, household appliances and other directions, can solve the problems of inability to guarantee the metallographic structure and performance of α+β type titanium alloy, and achieves good fatigue resistance and manufacturing. The effect of low cost and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

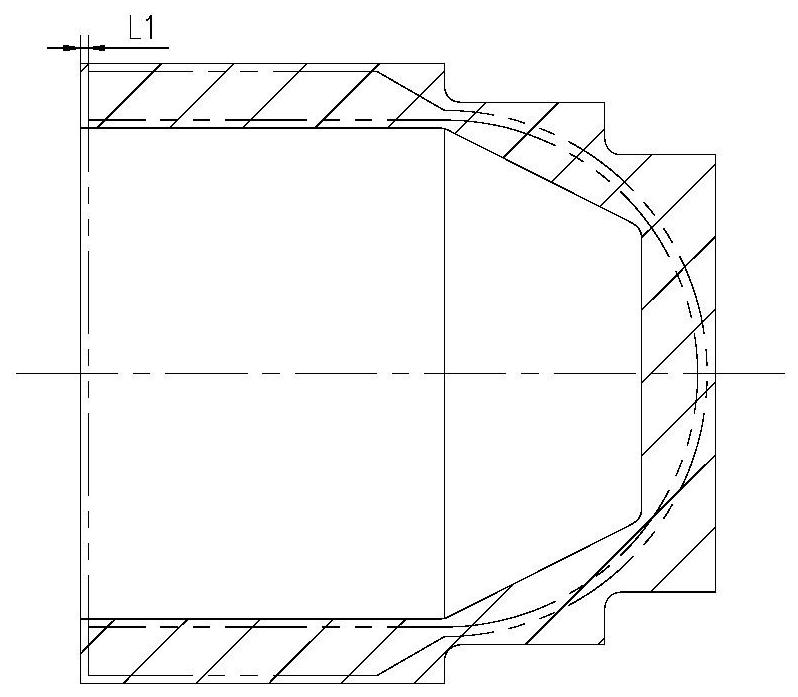

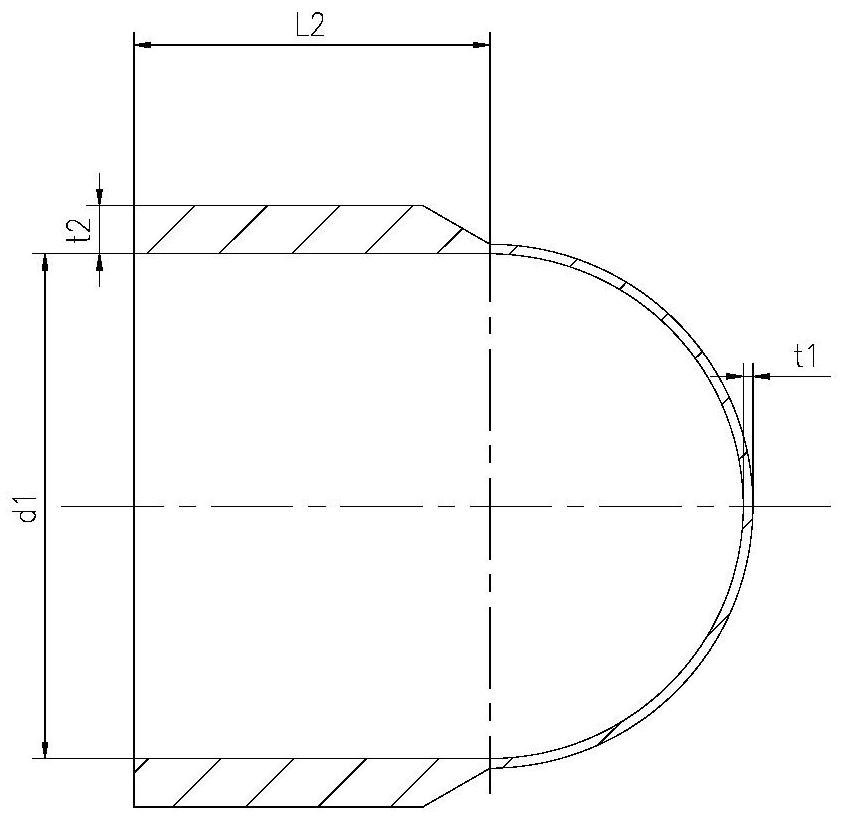

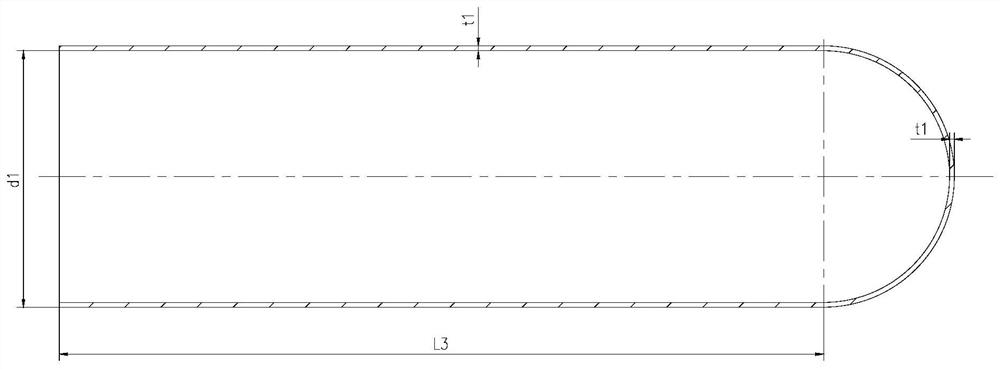

[0067] For a TC4 titanium alloy high-pressure seamless gas cylinder for a certain type of ship, its inner diameter d1 is 200mm, the length of the cylindrical section L4 is 500mm, and the wall thickness t1 is 4mm. The forming and processing methods of the titanium alloy high-pressure seamless gas cylinder for ships are specific as follows:

[0068] 1) forging blank forging

[0069] The titanium alloy round steel billet is forged into a forging billet. In order to improve the material utilization rate and reduce the material cost, one end of the outer circular surface of the forging billet is a stepped surface. Correspondingly, one end of the inner surface of the forging billet is a circular table surface; the other end of the forging billet is There is a machining allowance L1=2mm for strong spinning on the periphery of the forging, and the forging temperature of the forging blank is 800°C.

[0070] 2) Power spinning blank processing

[0071] The forging blank is numerically ...

Embodiment 2

[0092] For a TC4 titanium alloy high-pressure seamless gas cylinder for a certain type of ship, its inner diameter d1 is 300mm, the length of the cylindrical section L4 is 700mm, and the wall thickness t1 is 6mm. The forming and processing methods of the titanium alloy high-pressure seamless gas cylinder for ships are specific as follows:

[0093] 1) forging blank forging

[0094] The titanium alloy round steel billet is forged into a forging billet. In order to improve the material utilization rate and reduce the material cost, one end of the outer circular surface of the forging billet is a stepped surface. Correspondingly, one end of the inner surface of the forging billet is a circular table surface; the other end of the forging billet is There is a machining allowance L1=3.5mm for strong spinning on the periphery of the forging, and the forging temperature of the forging blank is 880 °C.

[0095] 2) Power spinning blank processing

[0096] The forging blank is numerical...

Embodiment 3

[0117] For a TC4 titanium alloy high-pressure seamless gas cylinder for a certain type of ship, its inner diameter d1 is 400mm, the length of the cylindrical section L4 is 1000mm, and the wall thickness t1 is 8mm. The forming and processing methods of the titanium alloy high-pressure seamless gas cylinder for ships are specific as follows:

[0118] 1) forging blank forging

[0119] The titanium alloy round steel billet is forged into a forging billet. In order to improve the material utilization rate and reduce the material cost, one end of the outer circular surface of the forging billet is a stepped surface. Correspondingly, one end of the inner surface of the forging billet is a circular table surface; the other end of the forging billet is There is a machining allowance L1=5mm for strong spinning on the periphery of the forging, and the forging temperature of the forging blank is 960°C.

[0120] 2) Power spinning blank processing

[0121] The forging blank is numerically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com