Patents

Literature

57results about How to "Avoid poor soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature lead-free solder alloy

ActiveCN105195915ALow melting pointReduce overheating warpageWelding/cutting media/materialsSoldering mediaRare-earth elementMechanical impact

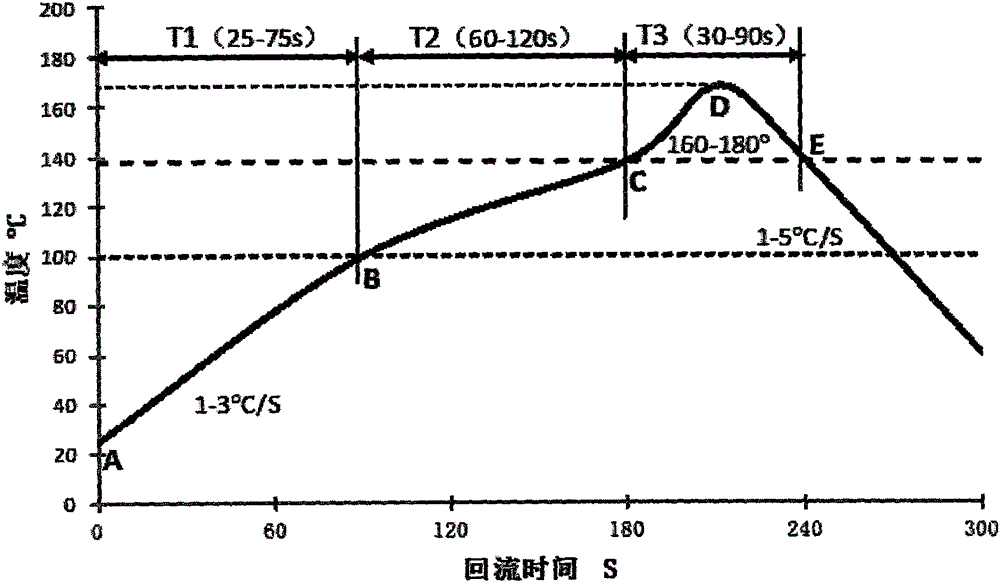

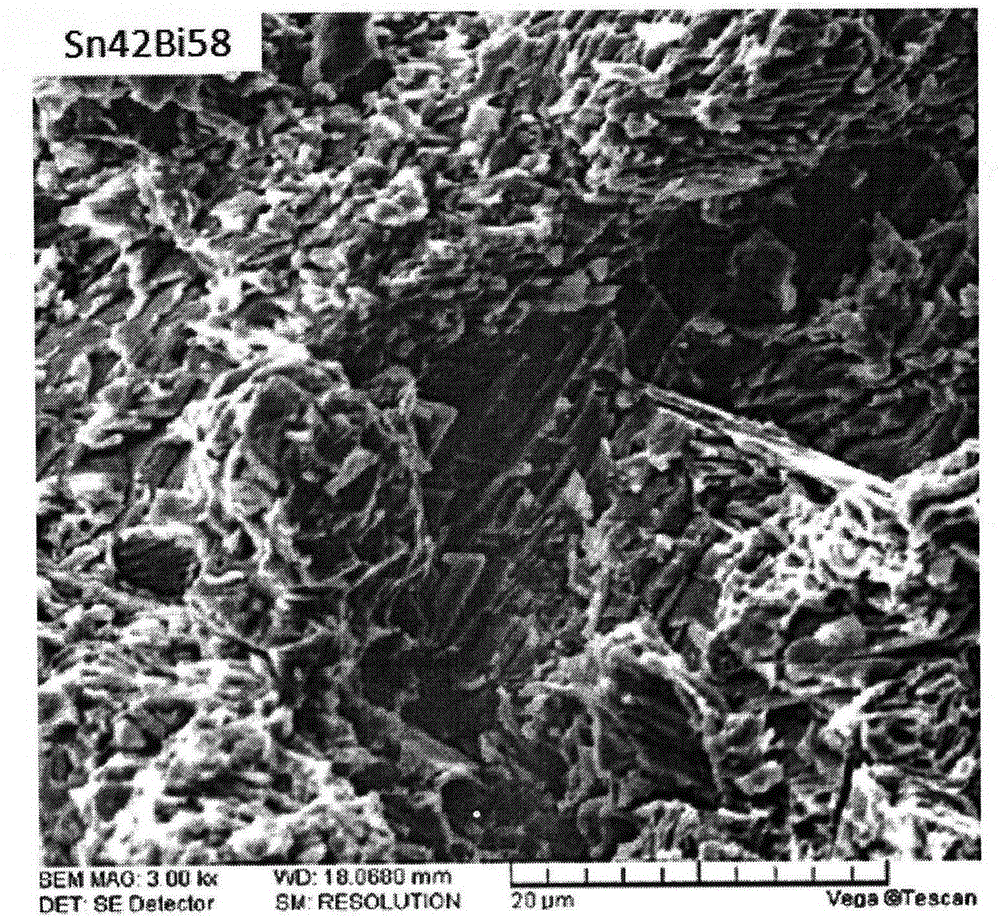

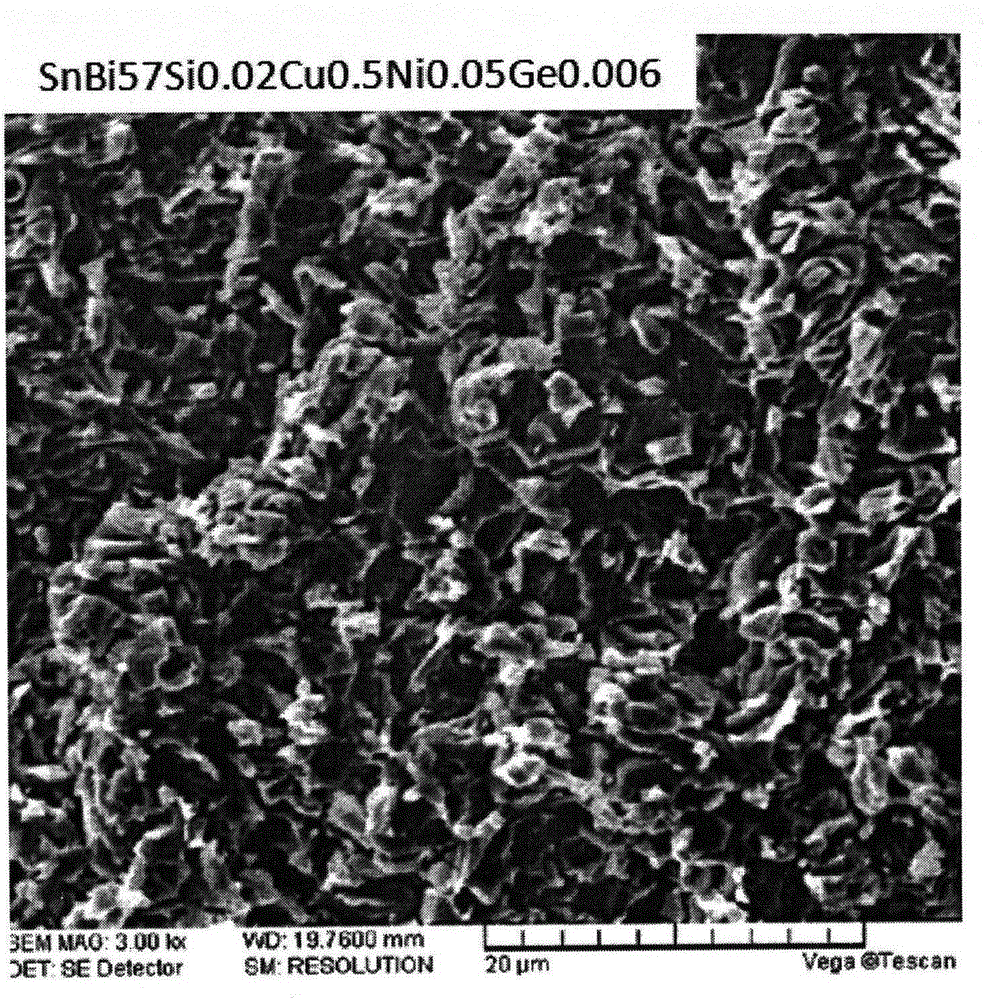

The invention discloses a low-temperature lead-free solder alloy, containing larger than or equal to 30% of and smaller than or equal to 60% of Bi, larger than 0.001% of Si and smaller than or equal to 0.02% of Si, as well as microalloy elements (alterant), rare earth elements, antioxidant elements and the balance of Sn and inevitable impurities. The large crystal grains of a Bi phase in a traditional Sn-Bi alloy system and the problem of reliability of brittle rupture of a welding joint is caused by that Bi is segregated at a Cu / Cu3Sn interface to form a brittle Bi layer in a long-term service process of the traditional Sn-Bi alloy system are effectively improved, and the mechanical impact and falling resistance of the traditional Sn-Bi system alloy can be greatly improved.

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

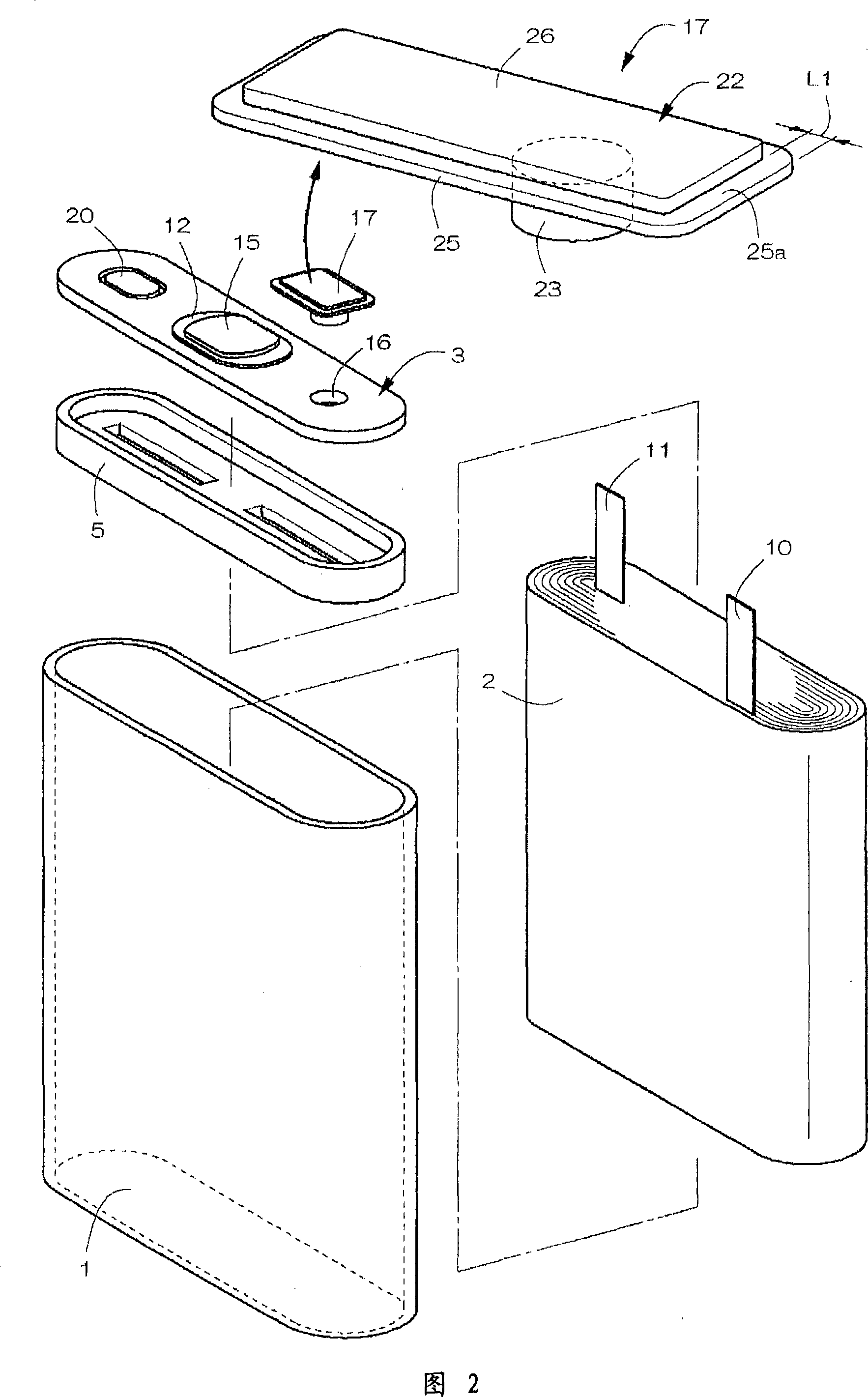

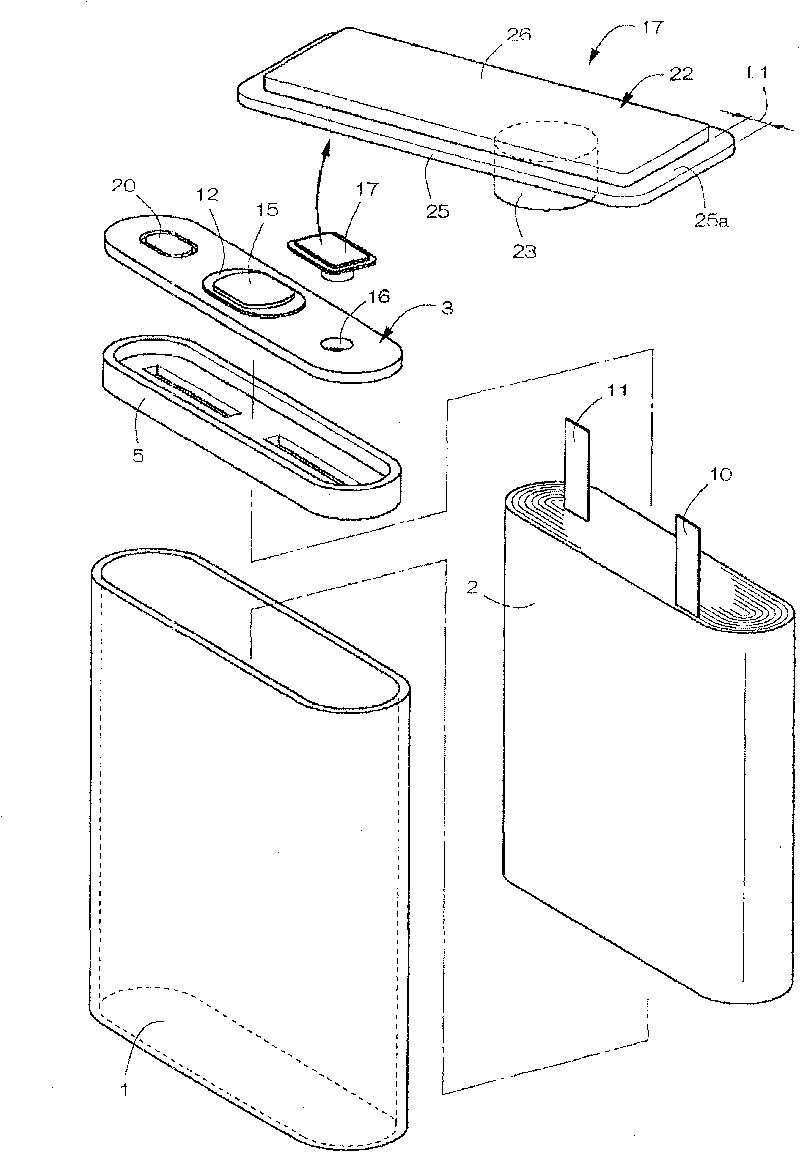

Battery pack

InactiveCN1976095ANo welding defectsEasy to operatePrimary cell to battery groupingSmall-sized cells cases/jacketsElectrical connectionBattery pack

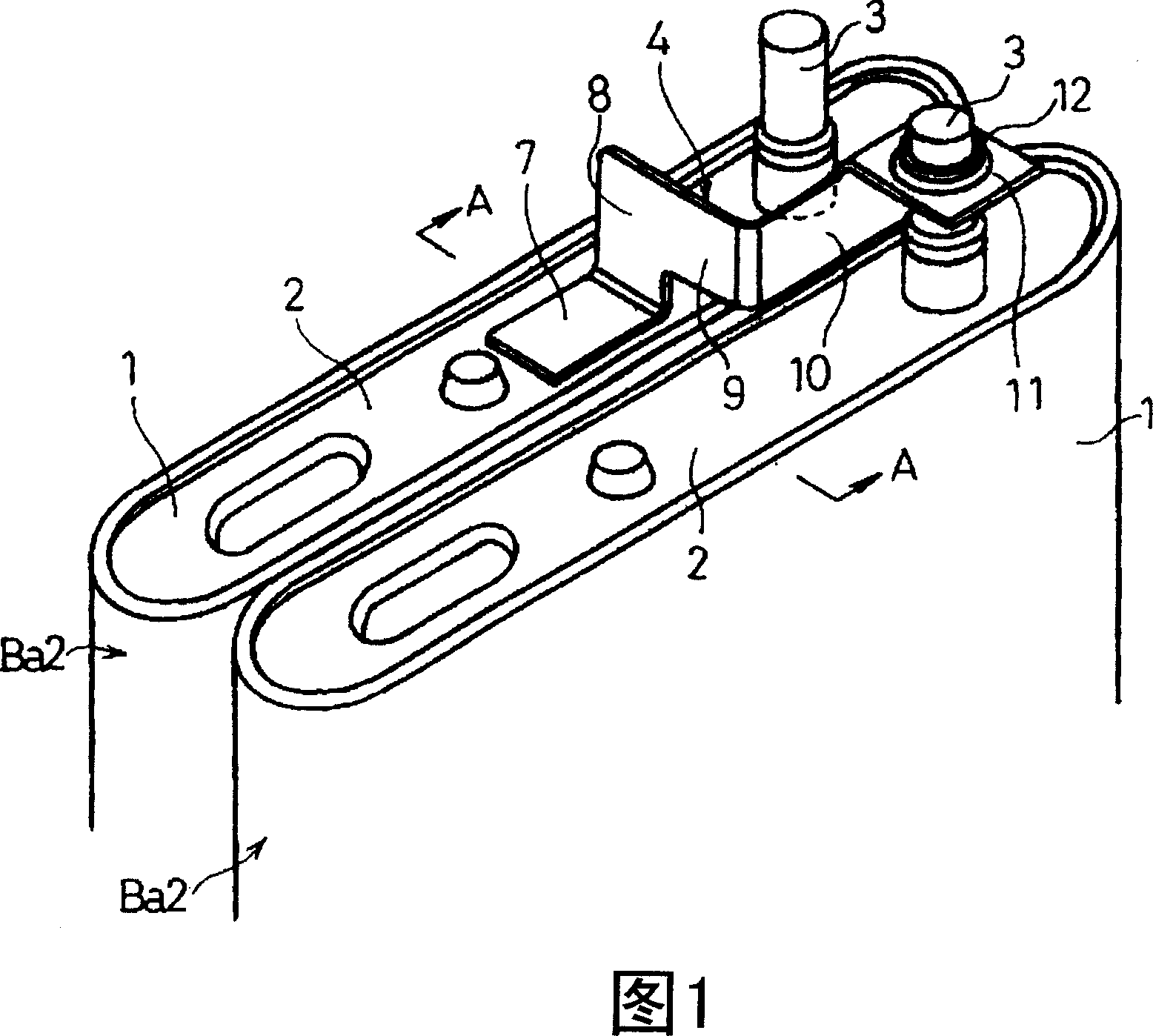

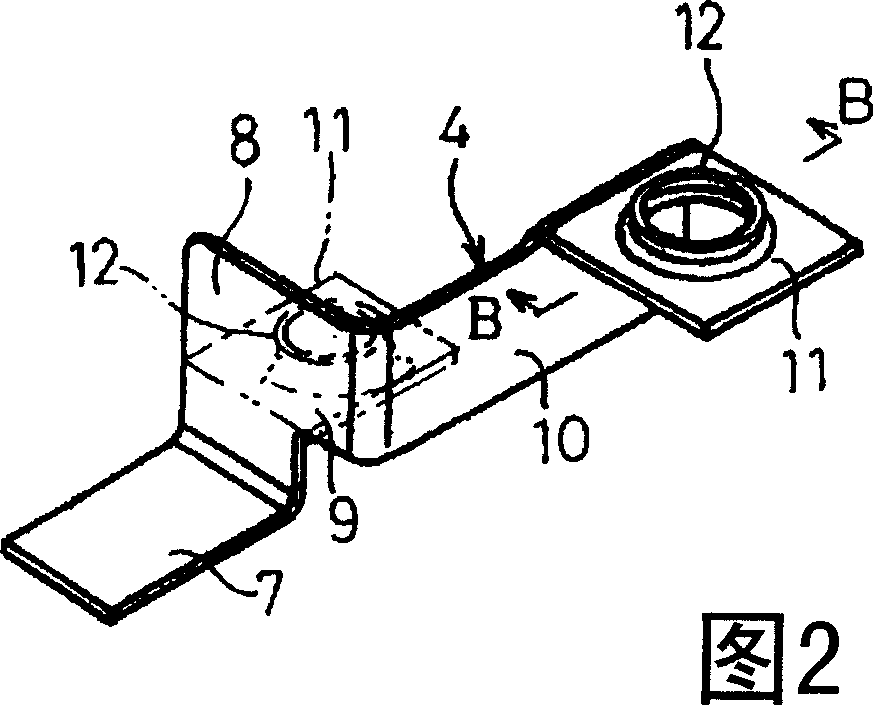

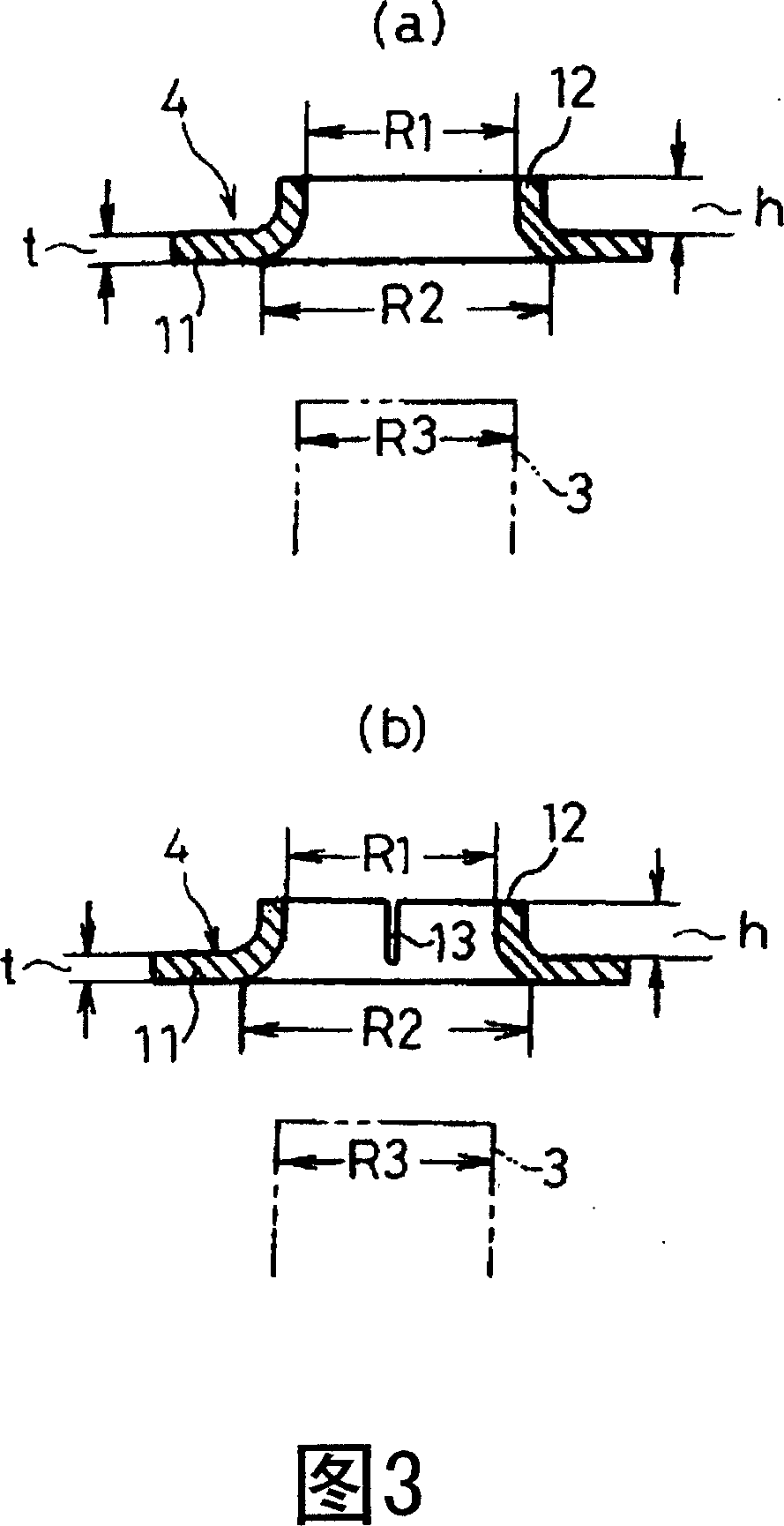

A battery pack is made up of a plurality of flat prismatic batteries arranged face to face, each battery having one electrode terminal protruding from one end face in the height direction of the battery case and this end face or a side face of the battery serving as the other electrode terminal. The connector for electrically connecting adjacent prismatic batteries includes a flat part that is welded to one electrode terminal of one prismatic battery of the adjacent prismatic batteries, and a cylindrical part that is fitted onto and welded to the other electrode terminal of the other prismatic battery. The cylindrical part is formed in an attachment part that extends from the flat part through an upright part in the direction in which the batteries are aligned. The connector enables reliable electrical connection of the prismatic batteries despite possible variation in height of the electrode terminals.

Owner:PANASONIC CORP

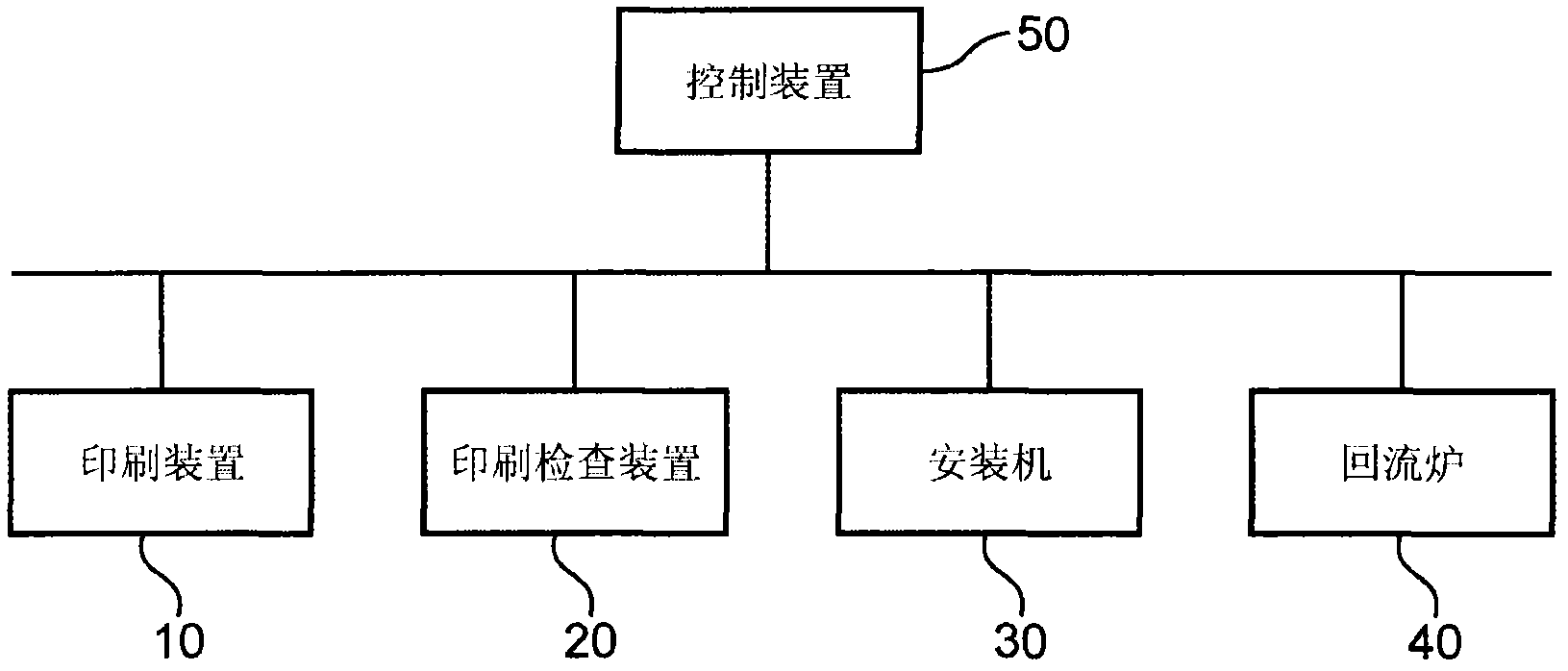

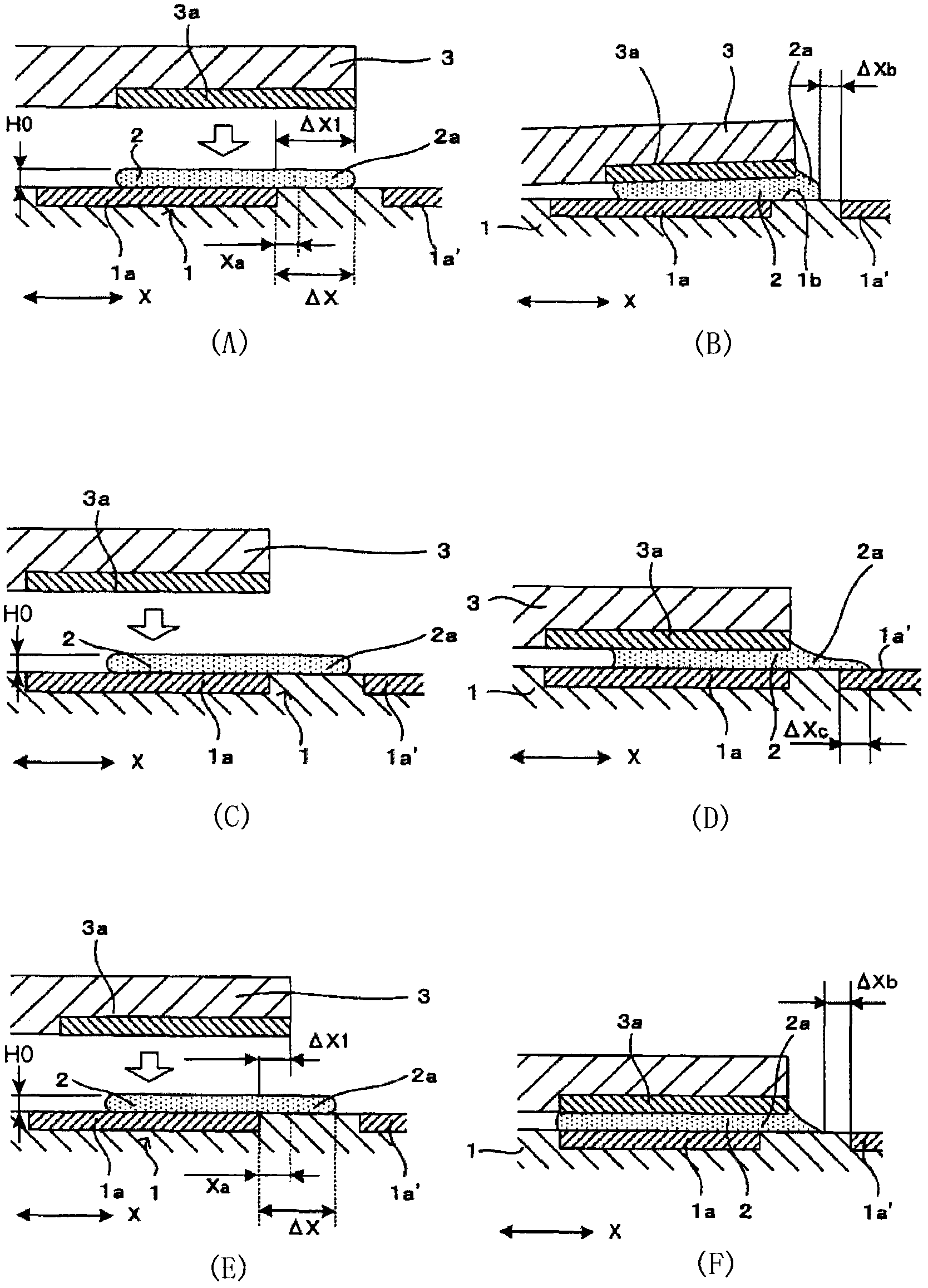

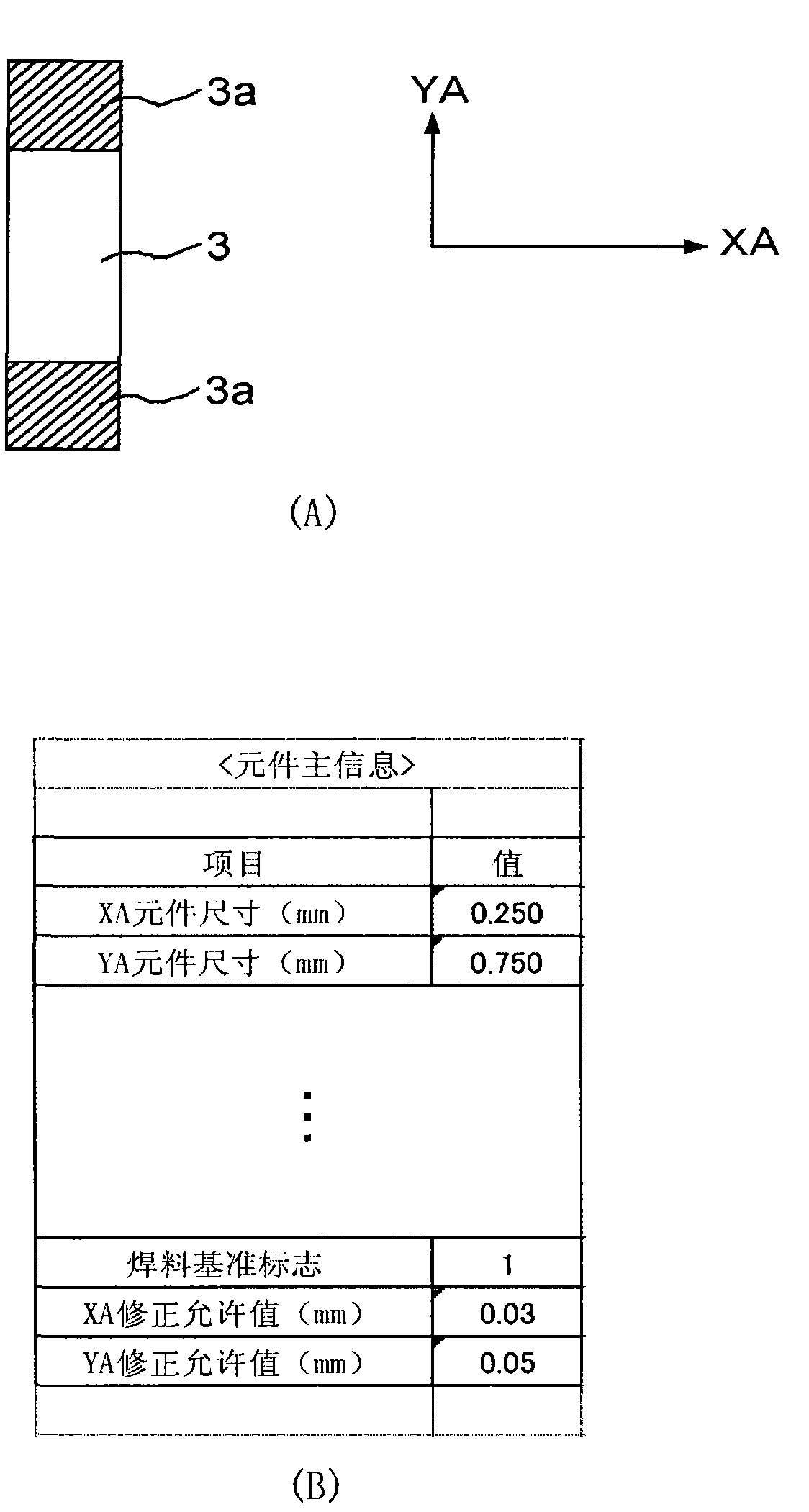

Element mounting device and element mounting method

ActiveCN102164473AAvoid poor solderingPrinted circuit assemblingElectrical componentsEngineeringSelf correction

The invention provides an element mounting device and an element mounting method. The element mounting device comprises a head assembly and a control part. Elements are installed on a substrate by the head assembly. The motion of the head assembly is controlled by the control part. Meanwhile, the mounting position of elements is adjusted according to the printing offset of the solder with respect to the electrode. When the printing offset is within a correction permissible range, the elements are installed on the substrate with the offset position of the solder on the substrate as a reference. The correction permissible range is set according to the self-correction effect exhibited by the fused solder, so that the mounting position of the elements is corrected to be at the electrode side. When the printing offset exceeds the correction permissible range, the elements are installed with the specified position close to the electrode as a reference within the offset range of the solder on the substrate. Therefore, the mounting position of the elements is adjusted according to the offset, so that the bad welding is prevented and the elements are satisfactorily installed on the substrate.

Owner:YAMAHA MOTOR CO LTD

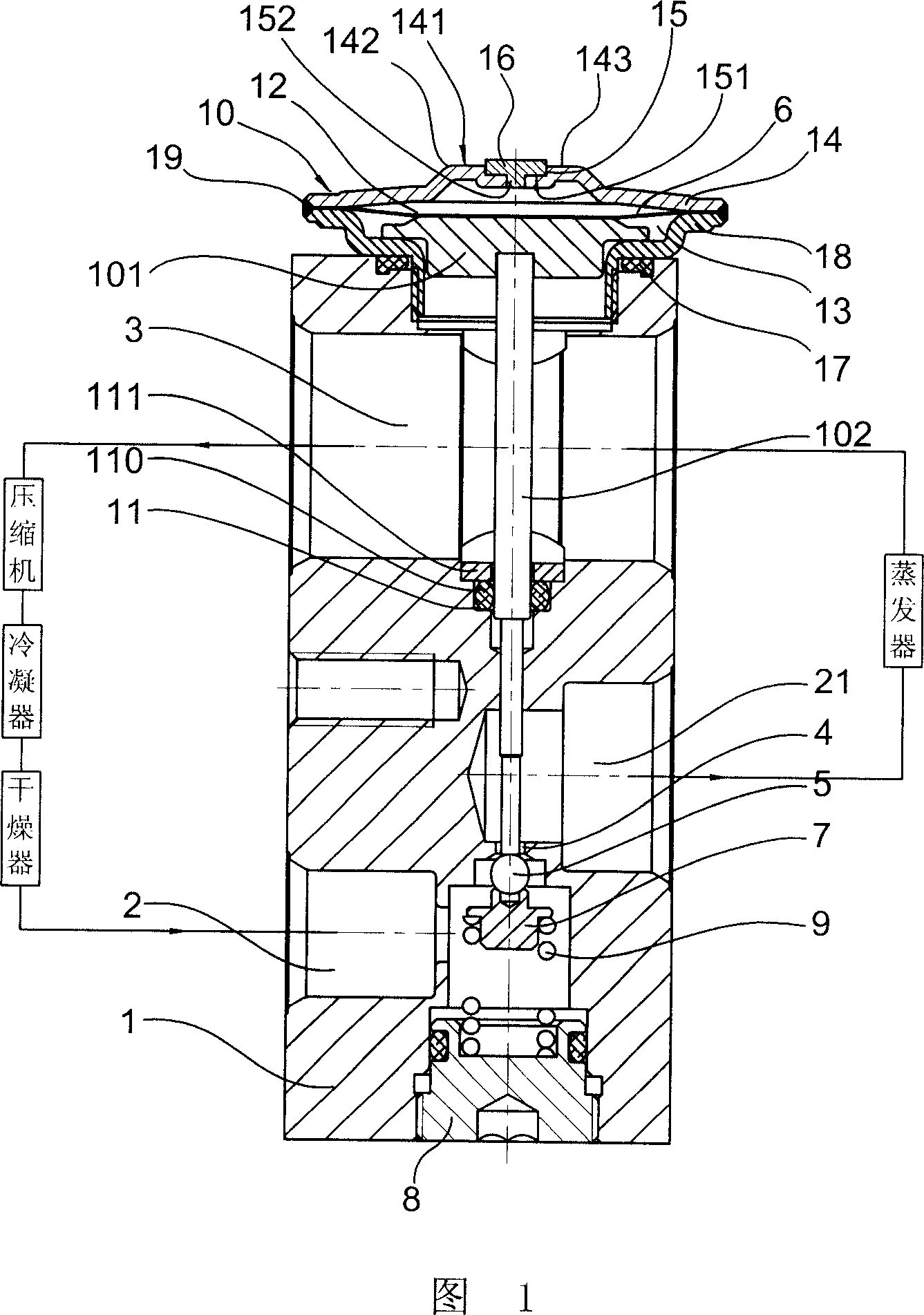

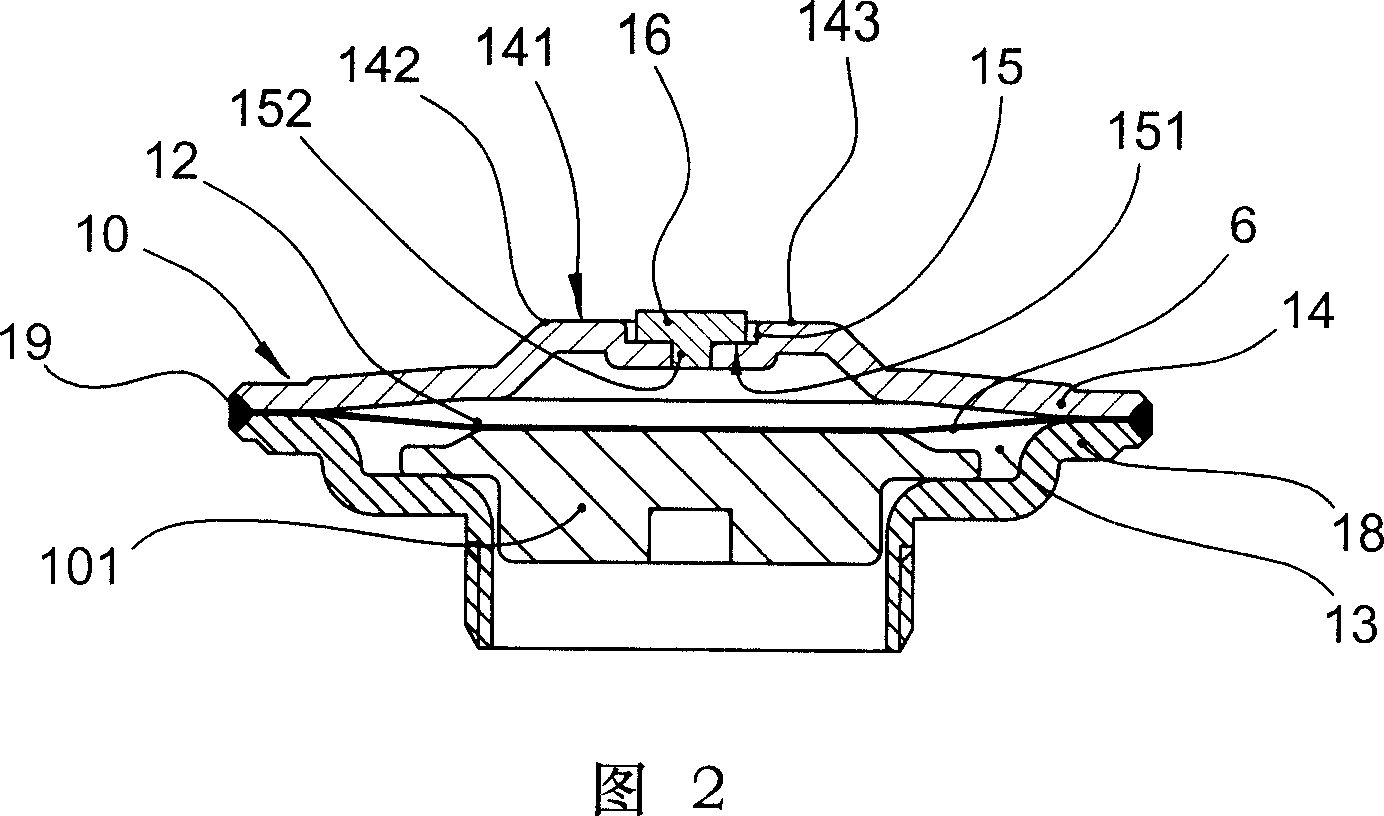

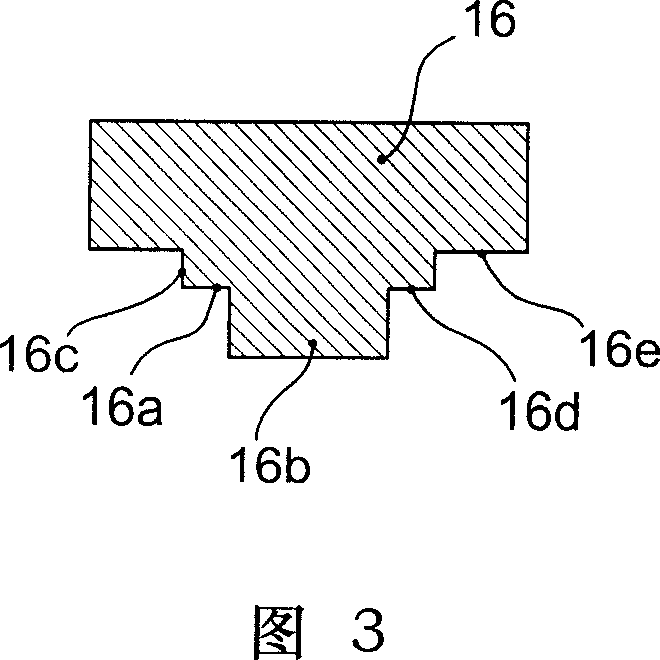

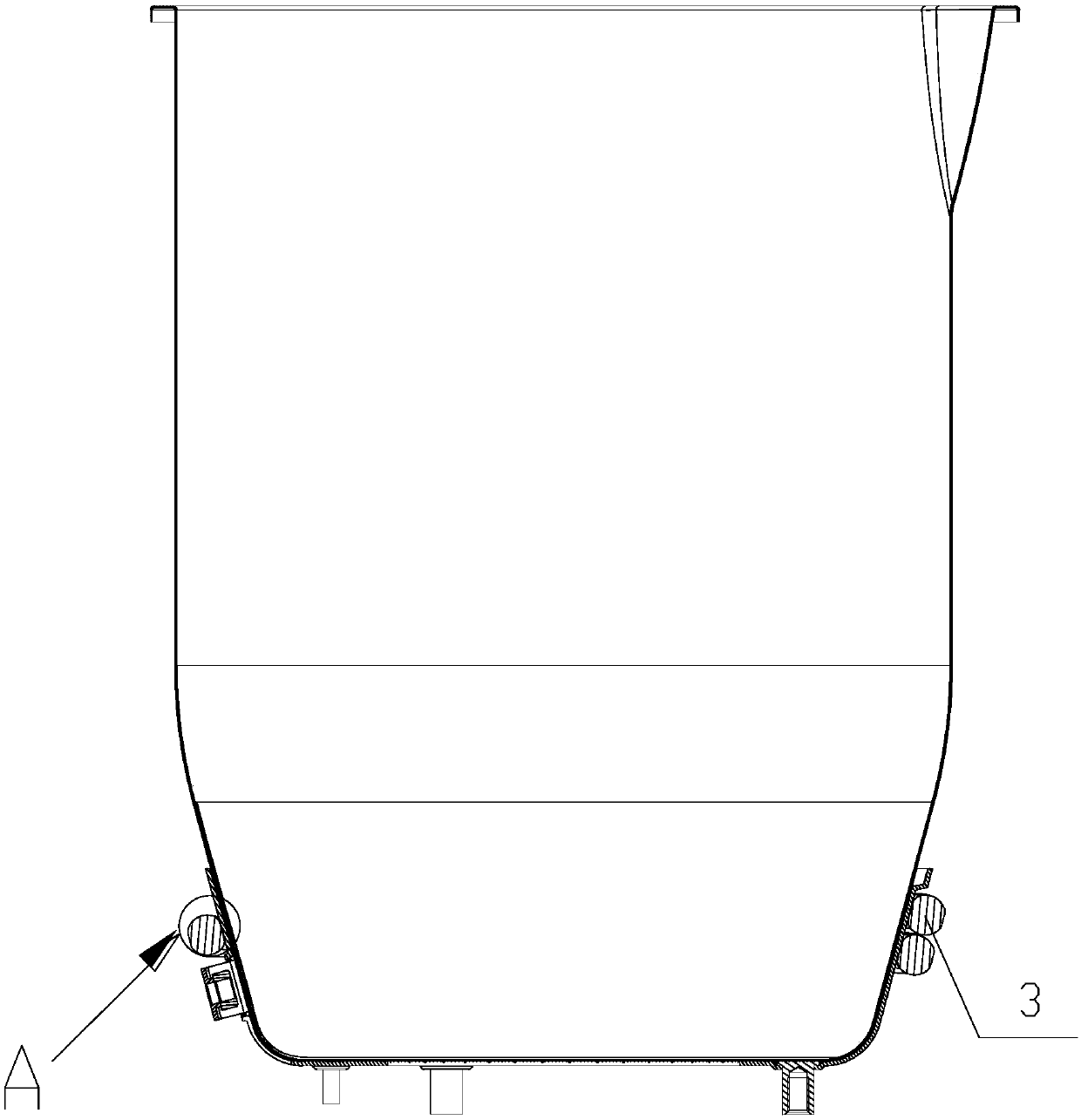

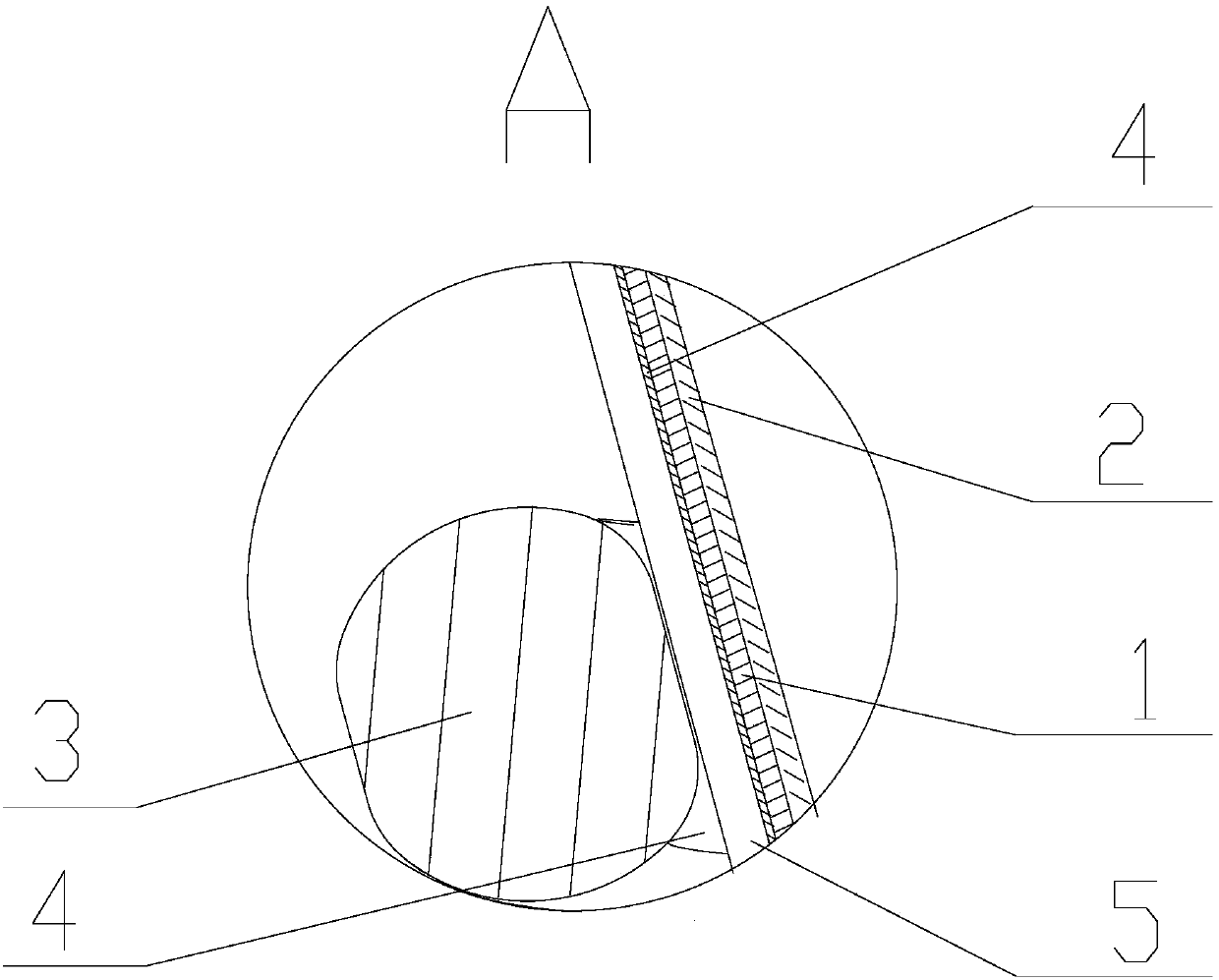

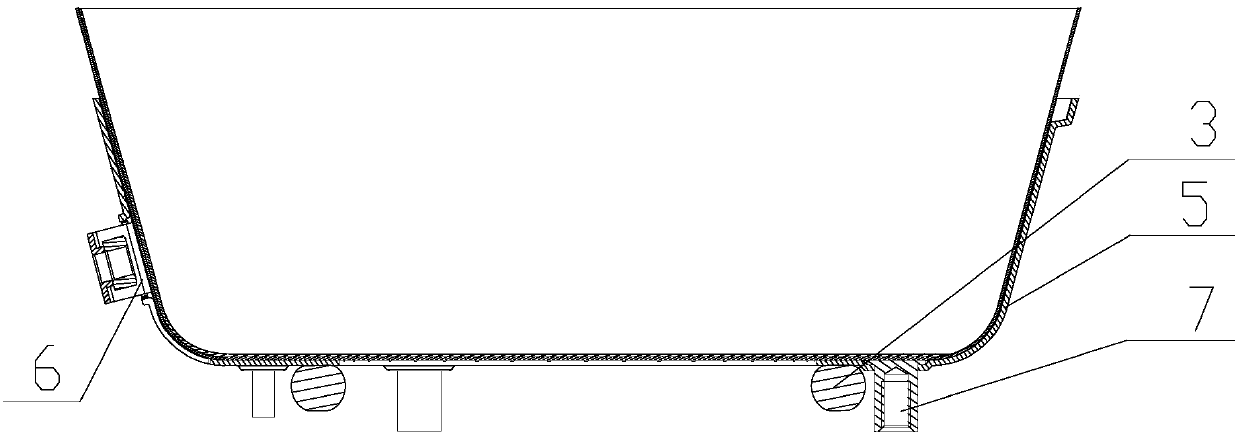

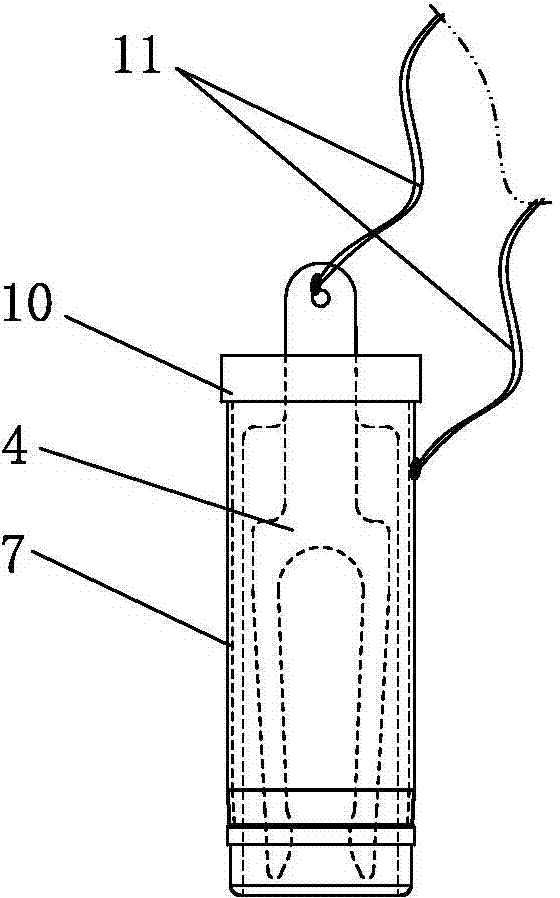

Thermal expansion valve

ActiveCN1932344AReliable weldingRealize energy savingOperating means/releasing devices for valvesFluid circulation arrangementElectrical resistance and conductanceStructural engineering

The present invention relates to a thermal expansion valve. It includes the following several main portions: valve core, diaphragm, air tight chamber and seal head. Said invention also provides the concrete structure of the above-mentioned every portion and the connection mode of all the above-mentioned portions. Besides, said also provides the concrete working principle of said thermal expansion valve and its concrete application method.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

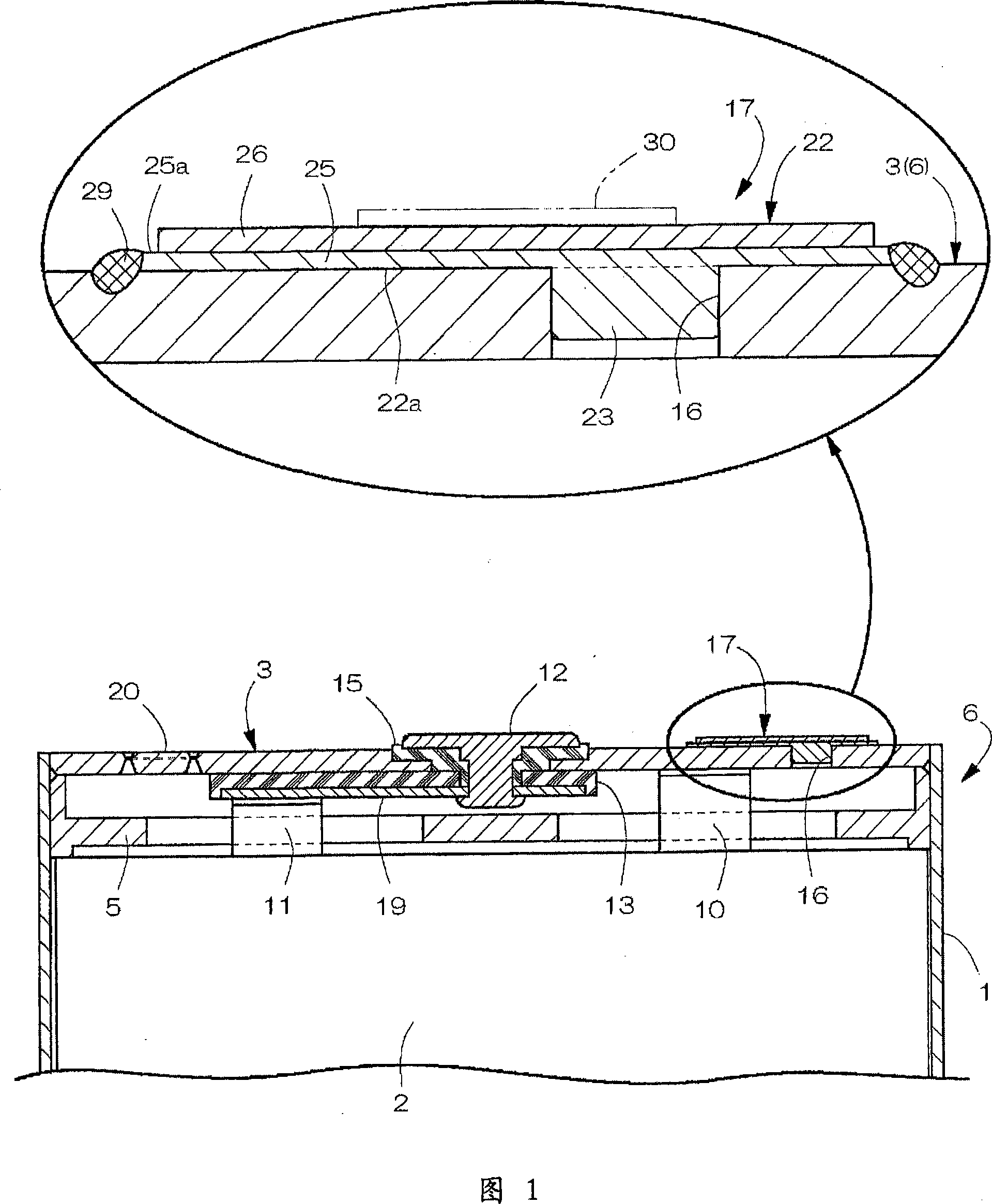

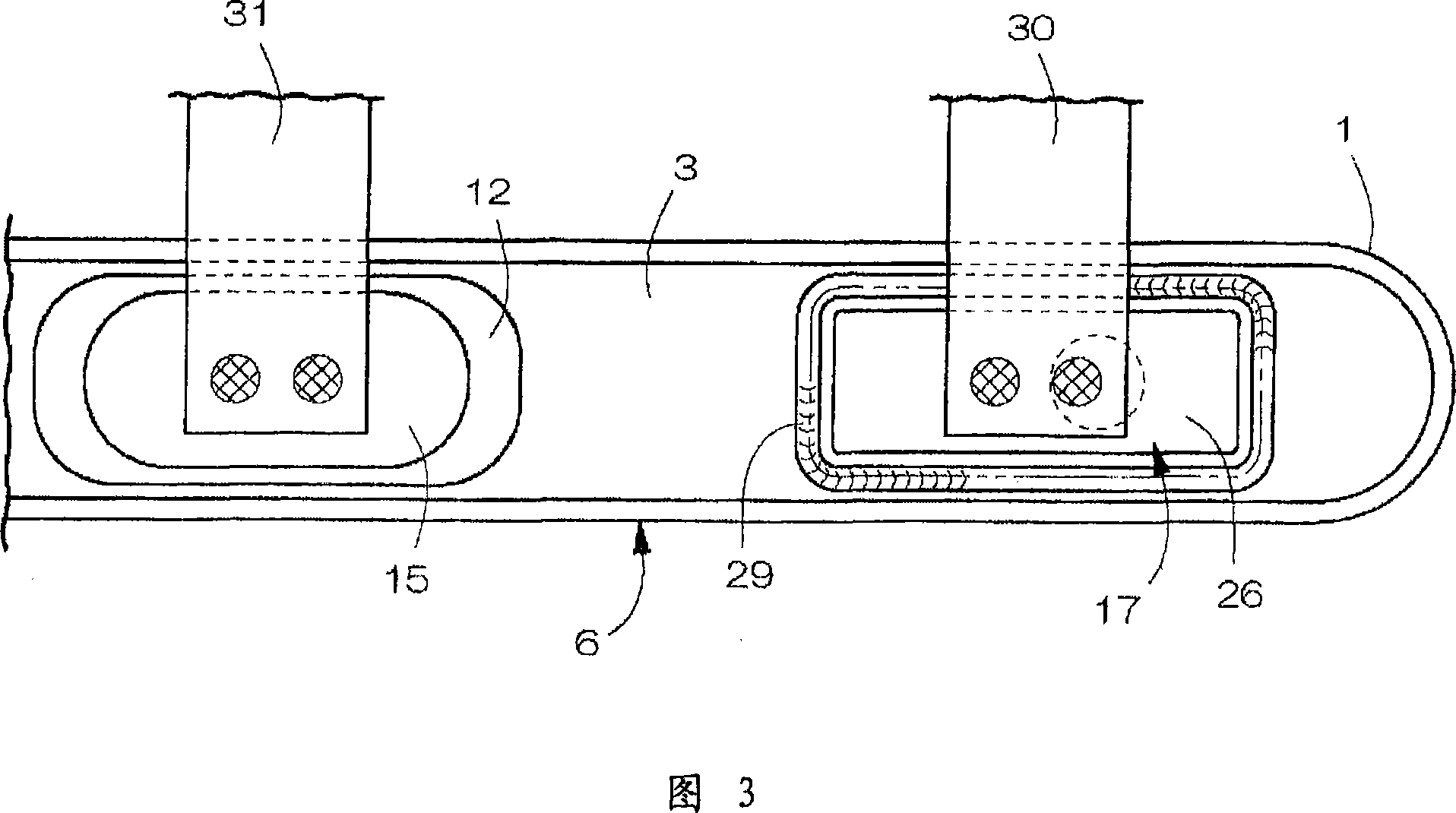

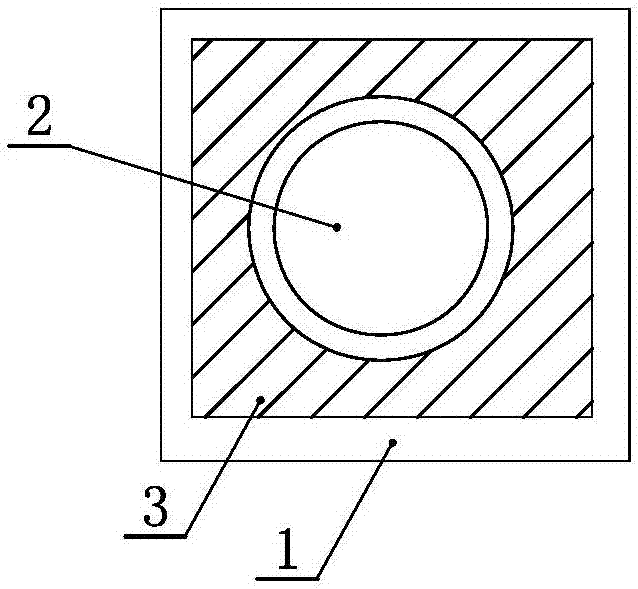

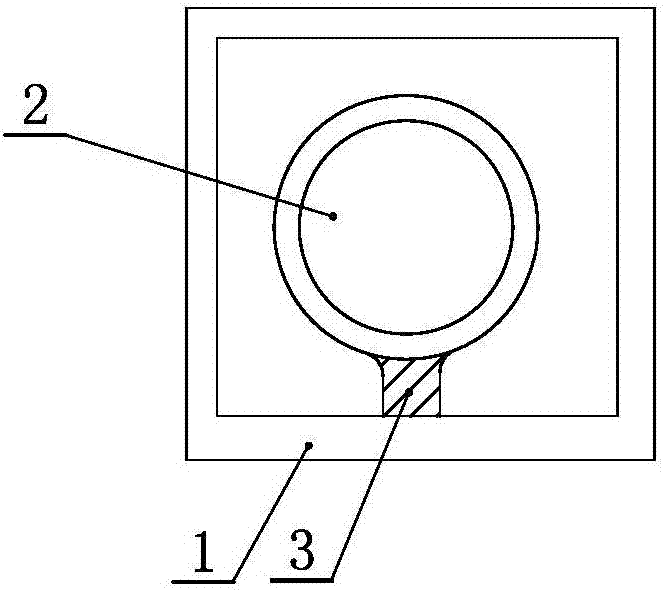

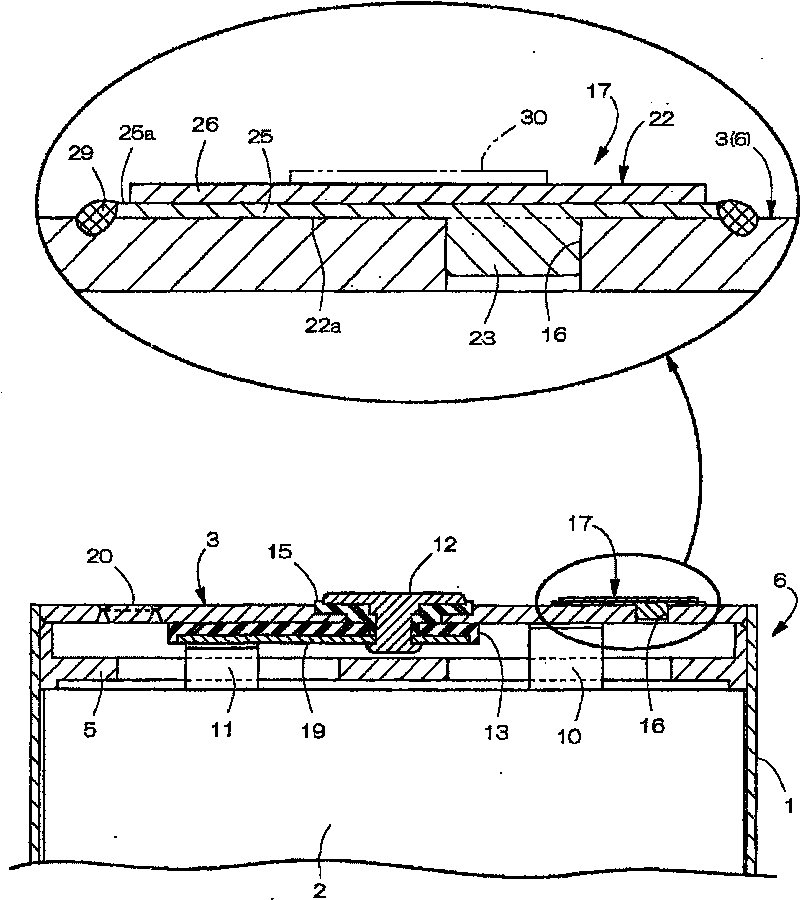

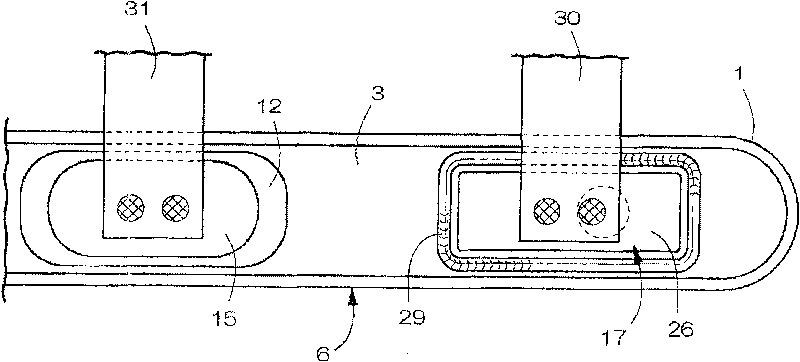

Sealing cell

ActiveCN101079475AEasy to weldPrevent the decrease of welding strengthFinal product manufactureSecondary cellsWelding defectMaterials science

To surely weld a sealing body to a battery case by reducing welding defects. After an electrolyte is injected into a battery case 6 from an electrolyte injection hole 16, the electrolyte injection hole 16 is closed by a sealing plug 17, and the sealing plug 17 is welded to a peripheral part of the electrolyte injection hole 16, whereby the electrolyte injection hole 16 is sealed. The sealing plug 17 is formed of a clad material formed by vertically joining an aluminum layer 25 to a nickel layer 26; the aluminum layer 25 is arranged on the battery case 6 side; and a peripheral part 25a of the aluminum layer 25 is projected to the outside of the sealing plug 17 relative to an edge of the nickel layer 26 and welded to a peripheral part of the electrolyte injection hole 16 by laser.

Owner:MAXELL HLDG LTD

Method for producing molybdenum component for magnetron cathode

InactiveCN101097825AUniform crystallizationGood consistency of densityCold cathode manufactureWire rodMiddle frequency

The invention discloses a method for producing molybdenum element of cathode of magnetron, mainly comprising that first, fills molybdenum powder into a special mould, to be compressed into a molybdenum end cap blank, then sinters the molybdenum end cap blank in inertia gas in a middle-frequency sensitive sinter furnace, while the sinter temperature is between 1650-1800Deg. C, and the sinter time is 2-6h, to obtain an upper molybdenum end cap and a lower molybdenum end cap which bent resistance strength is higher than 35kg / mm2, second, uses laser welding to weld the upper and lower molybdenum end caps respectively with an annular welding sheets together, third, welds the upper molybdenum end cap welded with the annular welding sheet with a central molybdenum lead wire rod together, and welds the lower molybdenum end cap welded with the annular welding sheet with a side molybdenum lead wire rod together. The molybdenum produced by The invention can reduce the fraction defective in welding process, reduce the production time and cost.

Owner:顾进跃

PCB character process

InactiveCN106961804AShort processShorten production timeNon-metallic protective coating applicationManufacturing technologyHeating time

The invention belongs to the technical field of printed circuit board manufacture, and relates to a PCB character process. The PCB character process comprises the steps of soldering resisting developing, A-surface printing, A-surface baking, B-surface printing, soldering resisting baking and cutting molding. Compared with prior art, the PCB character process has advantages of reducing a technological flow, reducing production time, realizing remarkable delivery time advantage, reducing heating time, reducing energy consumption, reducing exhaust processing cost, satisfying a low-carbon development requirement, preventing defective welding caused by pollution in multiple time of board baking, and improving product reliability.

Owner:PLOTECH TECH KUNSHAN CO LTD

Low alloy steel welding rod and manufacturing method thereof

InactiveCN104889591AReasonable ingredientsQuality improvementWelding/cutting media/materialsSoldering mediaManganeseRutile

The invention discloses a low alloy steel welding rod. The low alloy steel welding rod comprises a metal welding core and a covering, wherein the metal welding core comprises a working part and a clamping part which are fixedly connected; the diameters of the working part and the clamping part are the same; the working part is an iron alloy wire; the clamping part is an aluminum magnesium alloy wire; the atomic ratio of aluminum to magnesium in the aluminum magnesium alloy wire is 3:2; the covering comprises the following components in parts by weight: 1-2 parts of feldspar, 2-5 parts of synthetic mica, 6-8 parts of rutile, 5-10 parts of fluorite, 2-4 parts of electrolytic manganese, 1-3 parts of sodium carbonate, 6-8 parts of nickel powder, 1-3 parts of zircon sand, 13-16 parts of iron powder and 30-40 parts of marble serving as a base. The components of the covering are rational, the quality of a weld joint can be effectively improved, and full combustion of the welding rod can be realized; automatic separation of a discharge electrode can be realized when the welding rod is used up, so the remaining of the discharge electrode is completely avoided, and the welding rod is particularly suitable for manual electric arc welding of a complex structure.

Owner:赵兰

Welding technology for improving flatness of welding head

The invention provides a welding technology for improving the flatness of a welding head. Unnecessary diffusion of soldering tin can be avoided, and poor welding caused by unflatness of the welding head can also be avoided. An aluminum sheet is added between the welding head and a welded product, the lower plane of the aluminum sheet is tightly attached to soldering tin, the welding head transfersheat for welding to the soldering tin through the aluminum sheet, and therefore the welded product can be welded into a whole through the soldering tin.

Owner:SUZHOU ANJIE TECH

Stainless steel welding rod and manufacturing method thereof

InactiveCN104889603AAutomatic disengagementAvoid residueWelding/cutting media/materialsSoldering mediaChemical industryFriction welding

The invention discloses a stainless steel welding rod and a manufacturing method thereof. The stainless steel welding rod comprises a metal welding core and a covering, wherein the metal welding core comprises a working part and a clamping part which are fixedly connected; the working part and the clamping parts have same diameter; the working part is an iron alloy wire; the clamping part is an aluminum-magnesium alloy wire; the working part comprises the following components in percentage by weight: smaller than or equal to 0.03 percent of C, 0.4-1.2 percent of Mn, 0.5-1.0 percent of Si, 13-15 percent of Cr, 5-6 percent of Ni and the balance of iron and inevitable impurities. According to the method, the working part and the clamping part are in friction welding to form the welding core, and the outer surface is coated with the covering. The stainless steel welding rod can realize automatic separation of the clamping part and a weld joint. The material of the covering of the working part is improved to be more suitable for welding of stainless steel to adapt to welding of various containers and pipelines in the fields such as chemical industry, energy sources and foods.

Owner:赵兰

Carbon steel welding rod and manufacturing method thereof

InactiveCN104942465AAutomatic disengagementAvoid residueWelding/cutting media/materialsSoldering mediaCopper platingMagnetite

The invention discloses a carbon steel welding rod and a manufacturing method thereof. The carbon steel welding rod comprises a metal core and a coating. The metal core comprises a work part and a clamping part which are fixedly connected. The outer surface of the work part is coated with the coating, the coating contains 17.0-20.0% of magnetite, 13.0-14.0% of ferromanganese, 12.0-16.0% of starch, 4.0-6.0% of ilmenite, 6.0-8.0% of rutile, 5.0-7.0% of magnesia, 4.0-7.0% of manganese carbonate, 1.0-2.0% of magnesuim-aluminium alloy and the balance microcrystalline cellulose. The work part is made of iron alloy wires, and the clamping part is made of copper-coated aluminum wires. The method includes the step that the work part and the clamping part are coated with the coating after rubbing with each other and being welded. According to the structure of copper-coated aluminum, on one hand, the clamping portion of welding tongs has good conductivity; meanwhile, oxidation failure of the clamping portion is also effectively avoided; moreover, color of a copper-coated layer has remarkable identifiability compared with a welding rod coating and a steel structure.

Owner:赵兰

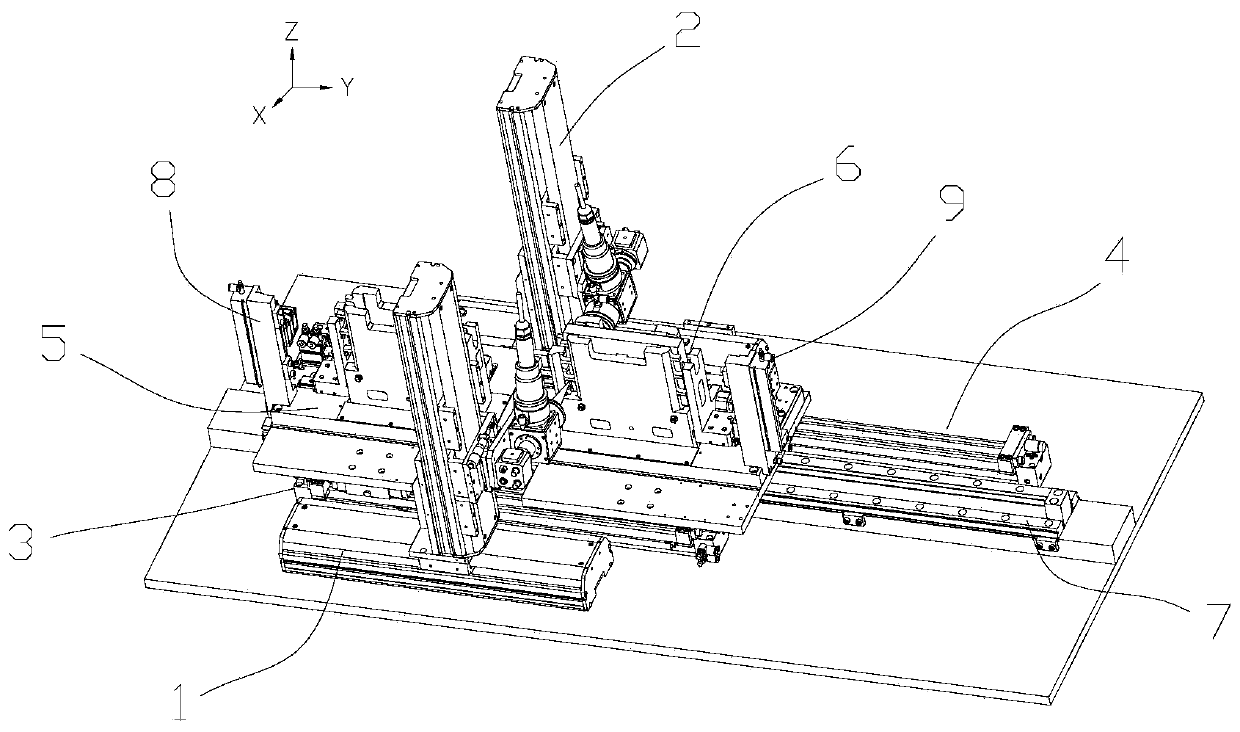

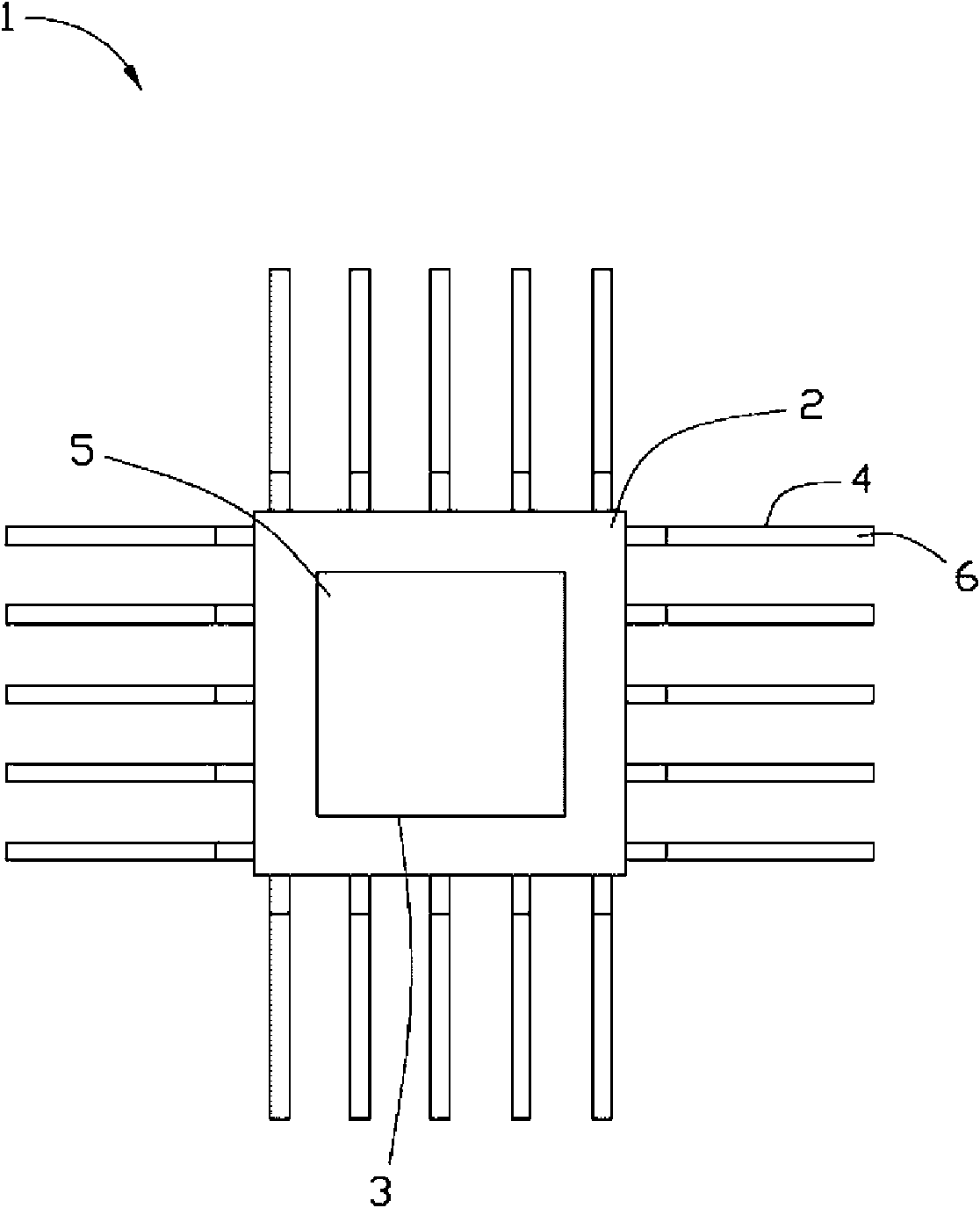

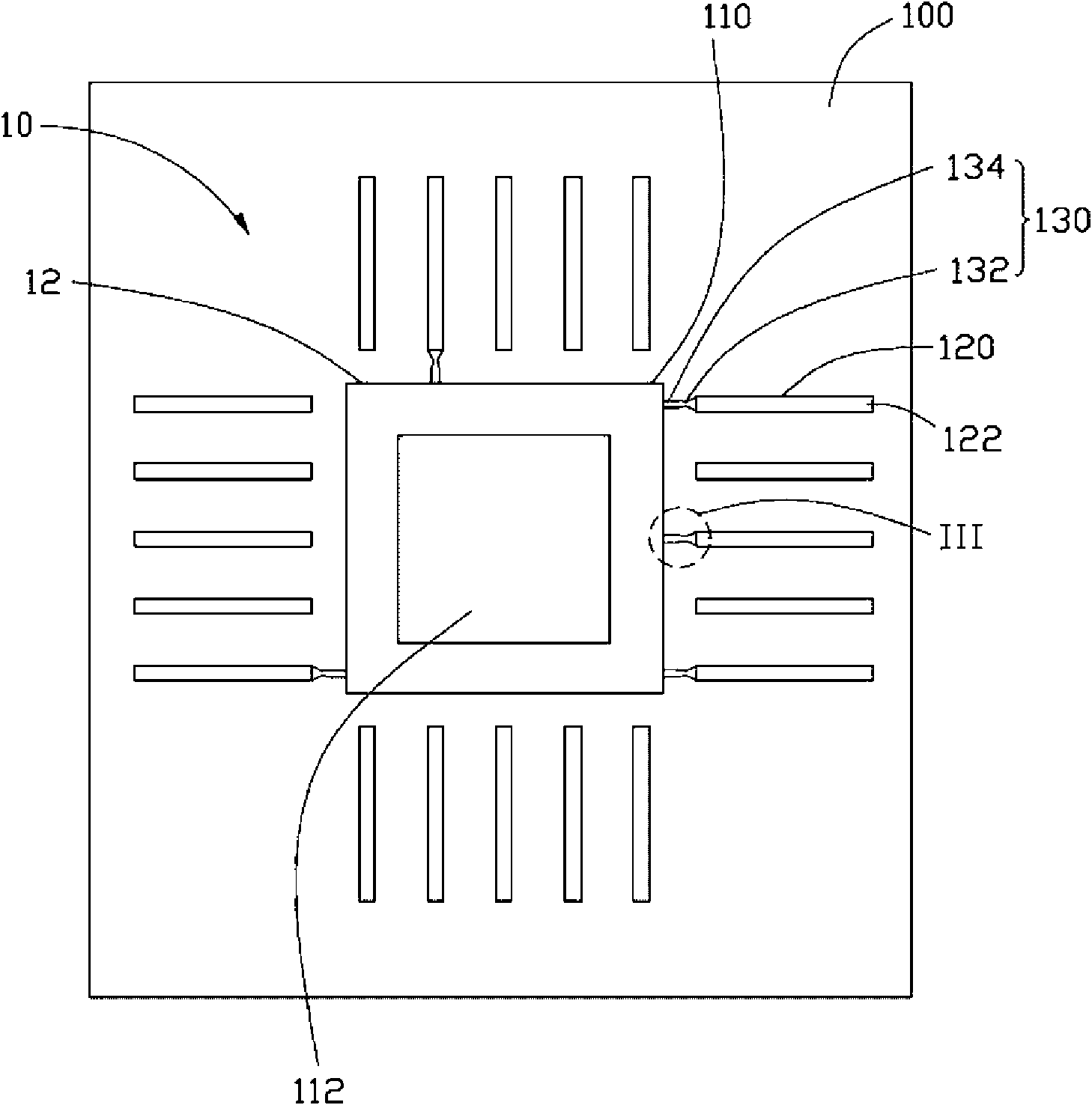

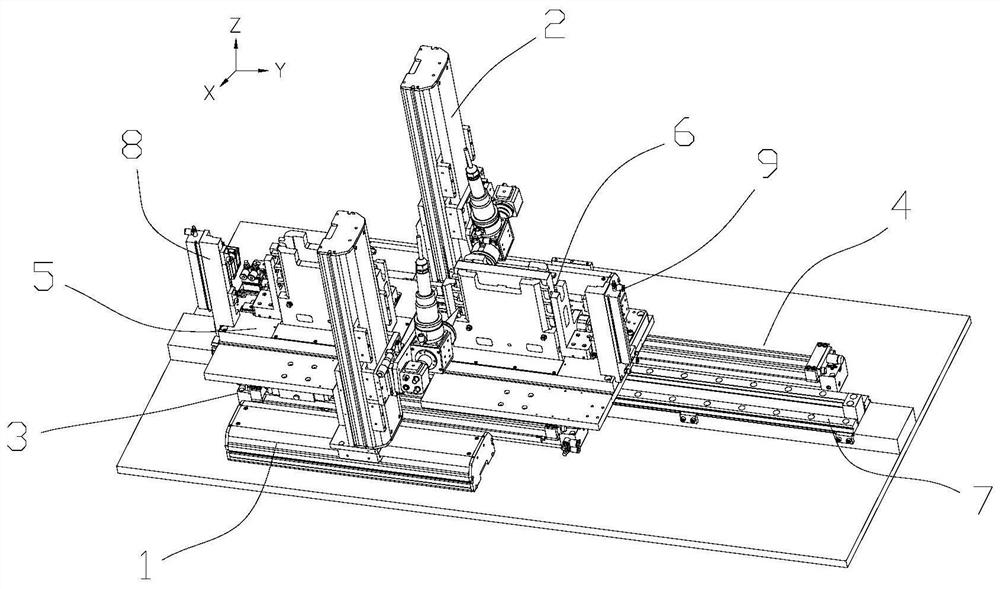

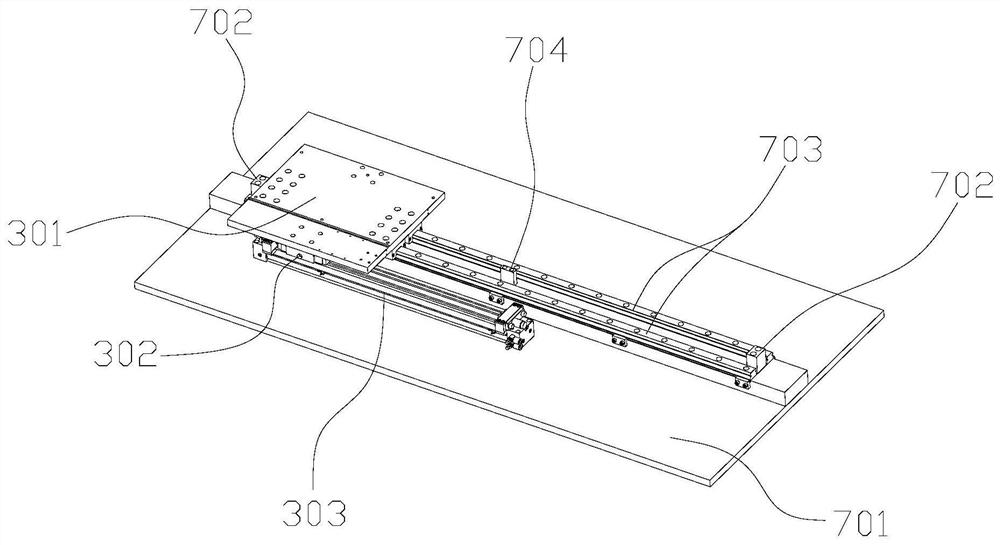

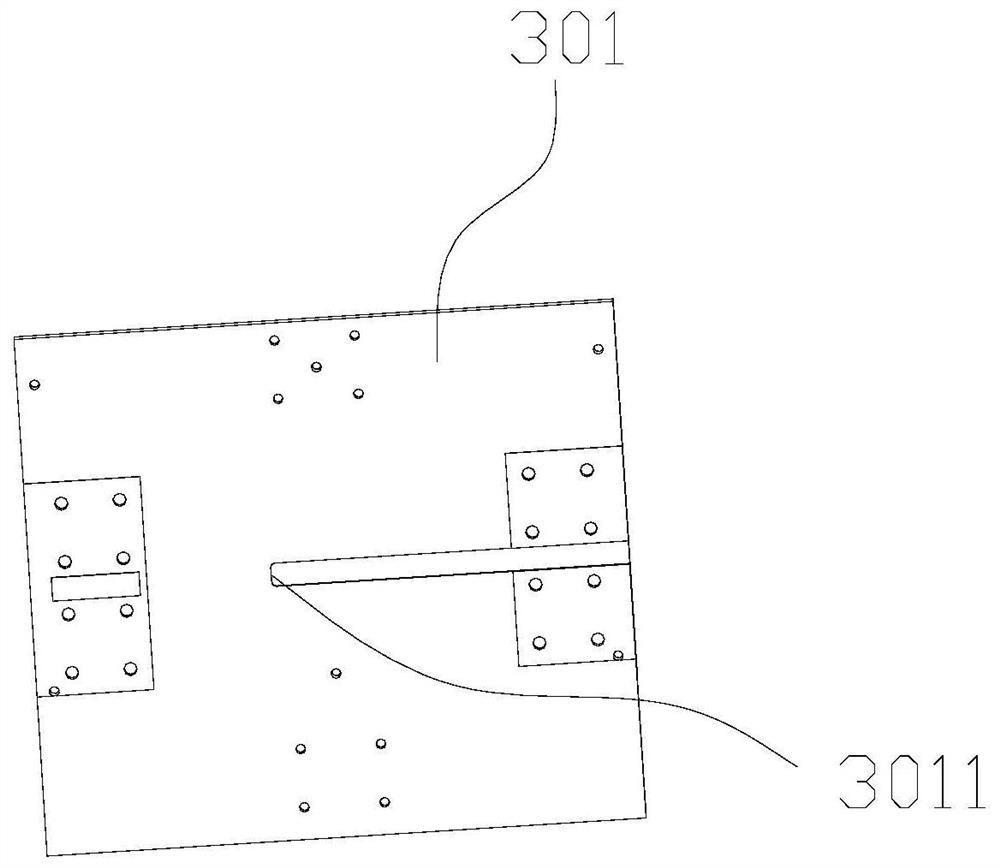

Power battery precise welding method and device

ActiveCN110814609AReduce mistakesPrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesPower batteryElectrical and Electronics engineering

The invention discloses a power battery precise welding device. The device comprises a rack, and further comprises two shifting mechanisms, two welding fixtures, two distance measuring modules and twowelding modules, wherein the two shifting mechanisms are movably mounted on the rack, and can be alternately positioned at a welding station and a discharging station; the two welding fixtures are installed on the two shifting mechanisms correspondingly and used for power battery clamping and positioning; the two distance measuring modules are installed on the two welding fixtures correspondinglyand used for measuring the distances between the distance measuring modules and the end faces of a power battery clamped in the welding fixtures; and the two welding modules are installed on the twosides of the shifting mechanisms correspondingly and carry out welding on the power battery in the welding fixtures simultaneously according to the measurement values of the distance measuring modules. A power battery precise welding method is also disclosed. According to the welding device and the welding method, a shell with low manufacturing precision and large self-deformation can be accurately positioned, and effective inspection and elimination of defective products after welding can be realized.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

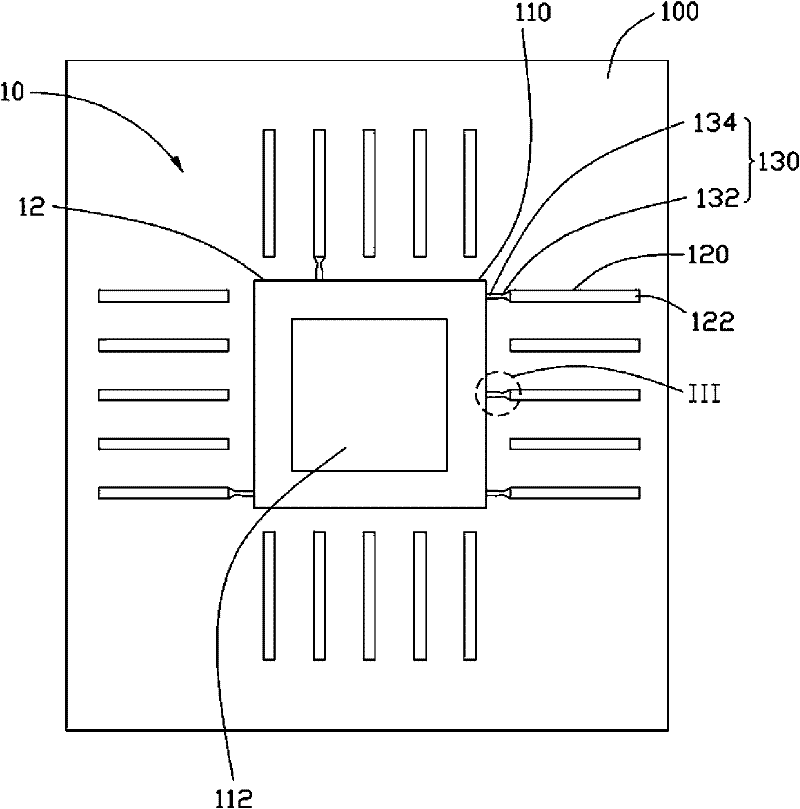

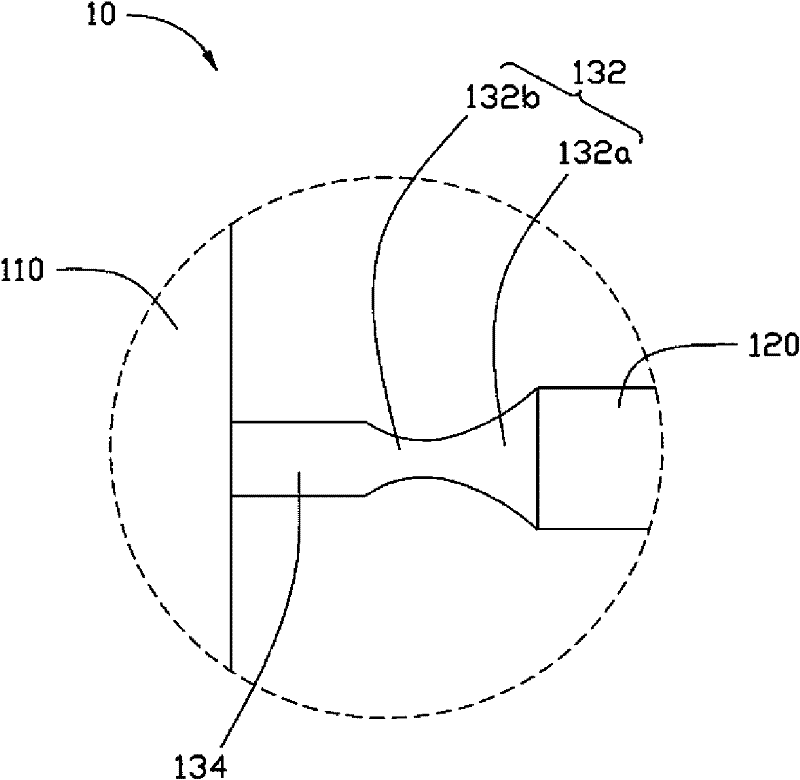

Surface mount structure and circuit board with same

ActiveCN102056405ABlock flowImprove placement qualityElectrical connection printed elementsPrinted circuit non-printed electric components associationWire widthCurrent limiting

The invention provides a surface mount structure used for fixedly mounting an electronic element with a pin and a welding chassis onto a circuit board. The surface mount structure comprises a pad formed on the circuit board, wherein the pad comprises a first pad welded with the bottom surface of the pin, a second pad welded with the bottom surface of the welding chassis and a connecting wire for connecting the first pad and the second pad. The structure is characterized in that the area of the surface of the second pad, which is opposite to the bottom surface of the welding chassis, is larger than the area of the surface of the first pad, which is opposite to the bottom surface of the pin; the space between the first pad and the second pad is smaller than 0.3mm; the connecting wire comprises a current-limiting part and a non-current-limiting part; the current-limiting part is connected with the first pad, and the non-current-limiting part is connected with the second pad; and the partial or overall wire width of the current-limiting part is smaller than the wire width of the non-current-limiting part.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

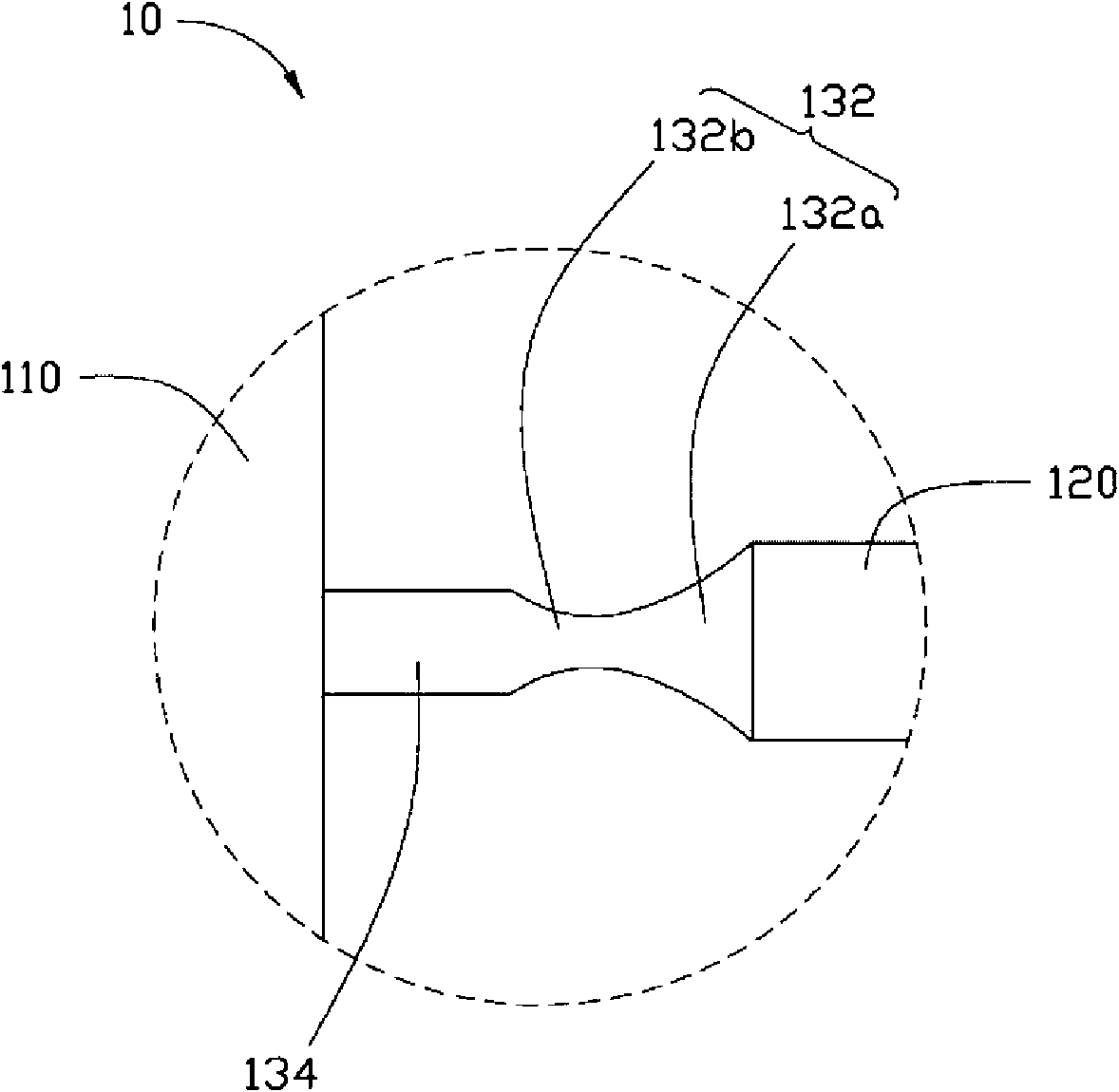

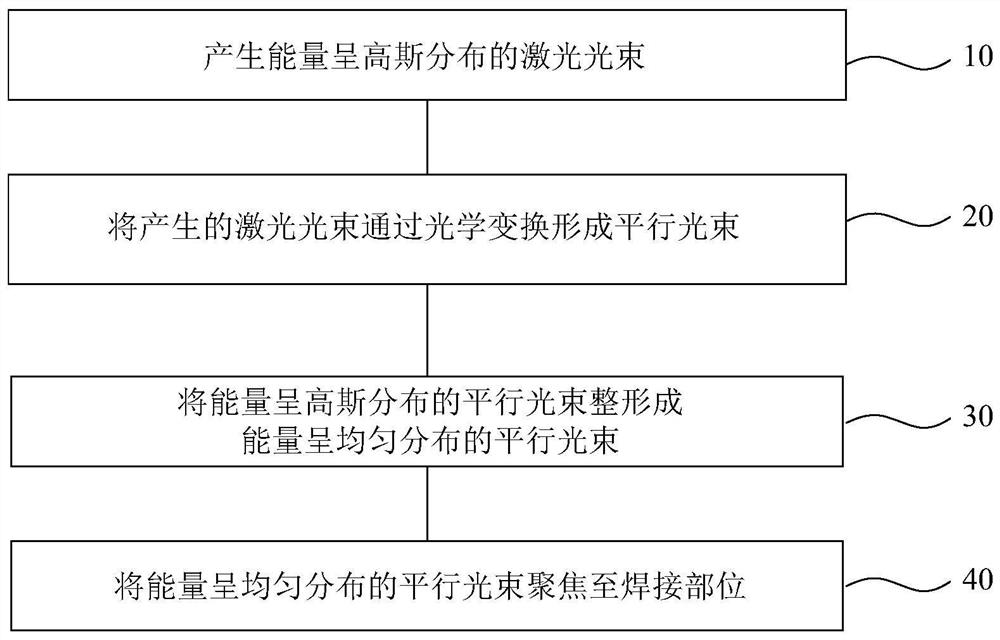

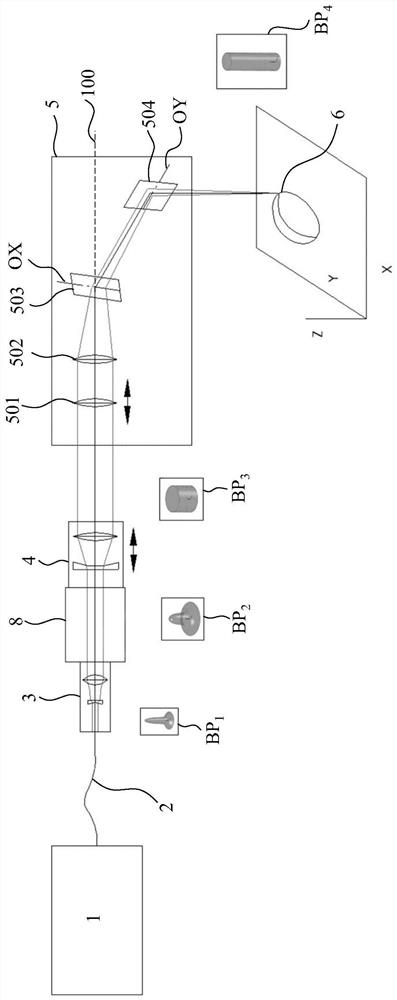

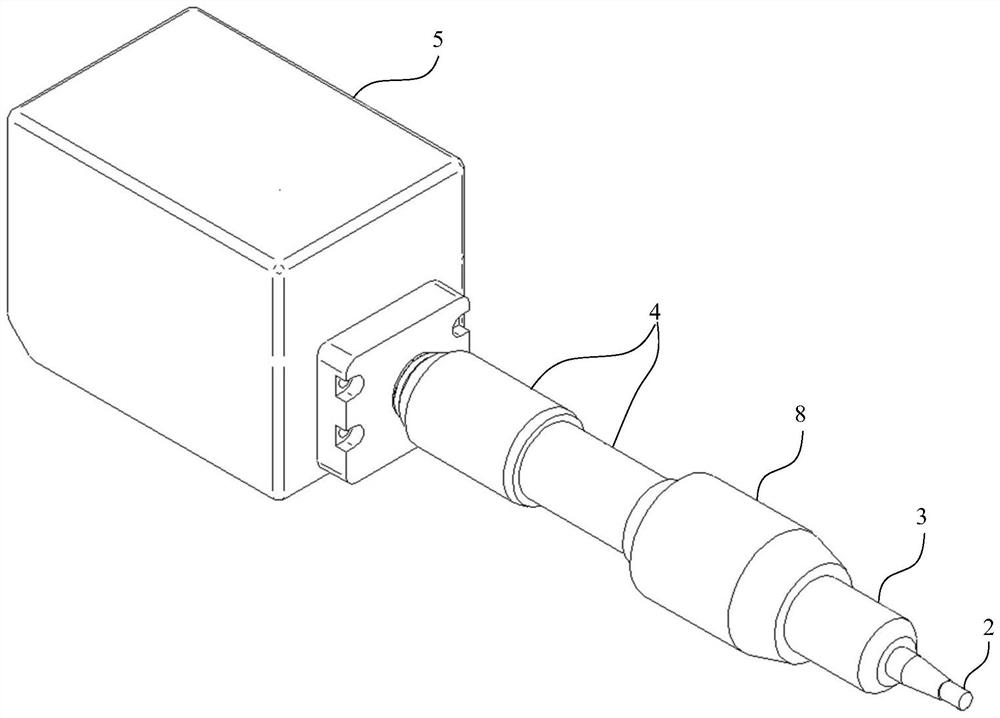

Laser welding method and device for laser welding

InactiveCN112548324AAvoid poor solderingReduce energy lossLaser beam welding apparatusPhysicsLaser soldering

The invention relates to a laser welding method. The method comprises the following steps: generating laser beams with energy in Gaussian distribution; enabling the generated laser beams to form parallel beams through optical transformation, wherein the energy of the parallel beams is in Gaussian distribution; shaping the parallel beams with energy in Gaussian distribution into parallel beams withenergy in uniform distribution; and focusing the parallel beams with energy in uniform distribution to a welding part. The invention also relates to a device for laser welding using the method. Withthe method and the device, the welding defects caused by uneven heating can be reduced, and meanwhile, the device for laser welding is simplified, so that welding is carried out under the condition that the relative position between the device and a welding piece is not changed.

Owner:BRANSON ULTRASONICS SHANGHAI

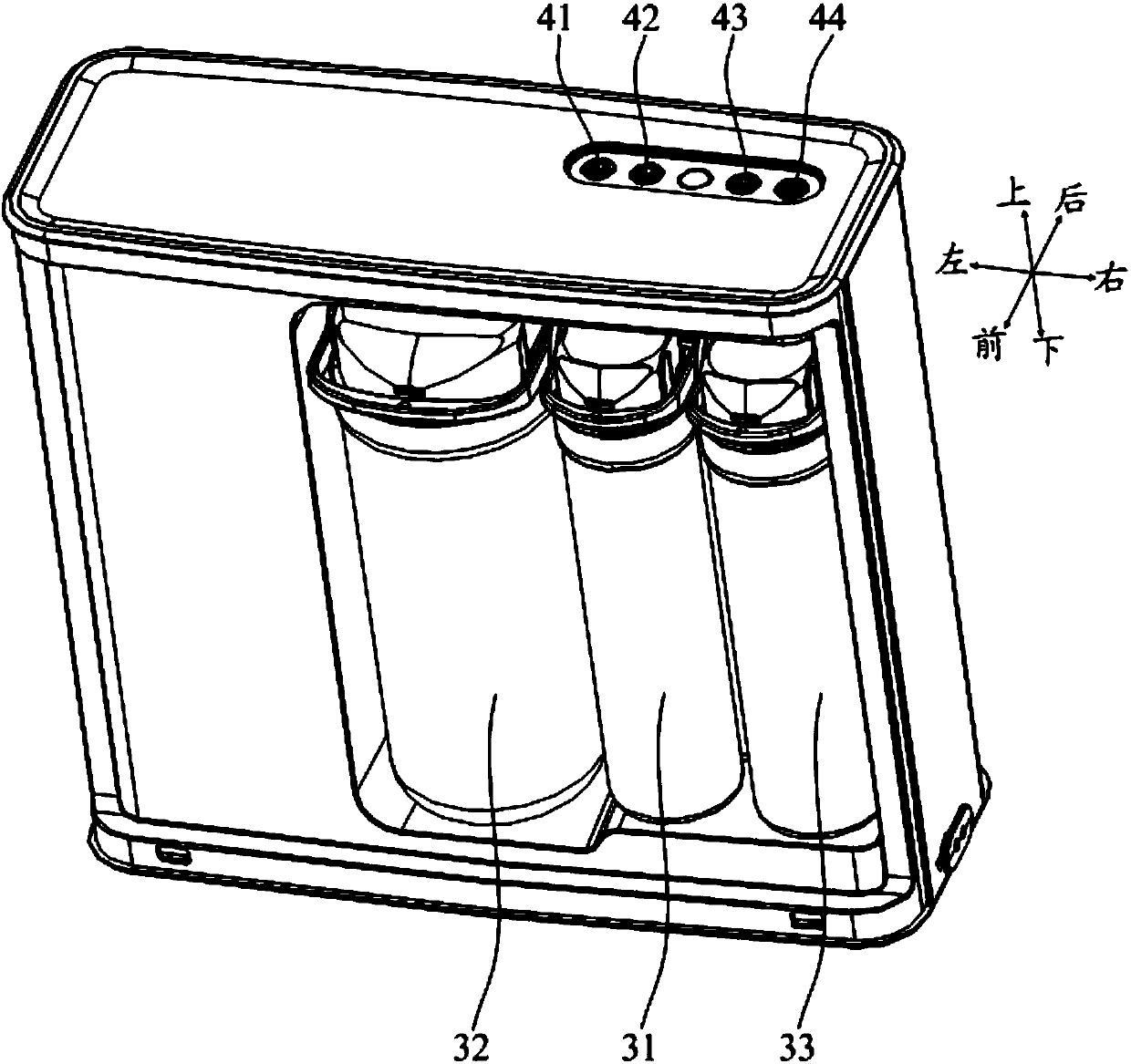

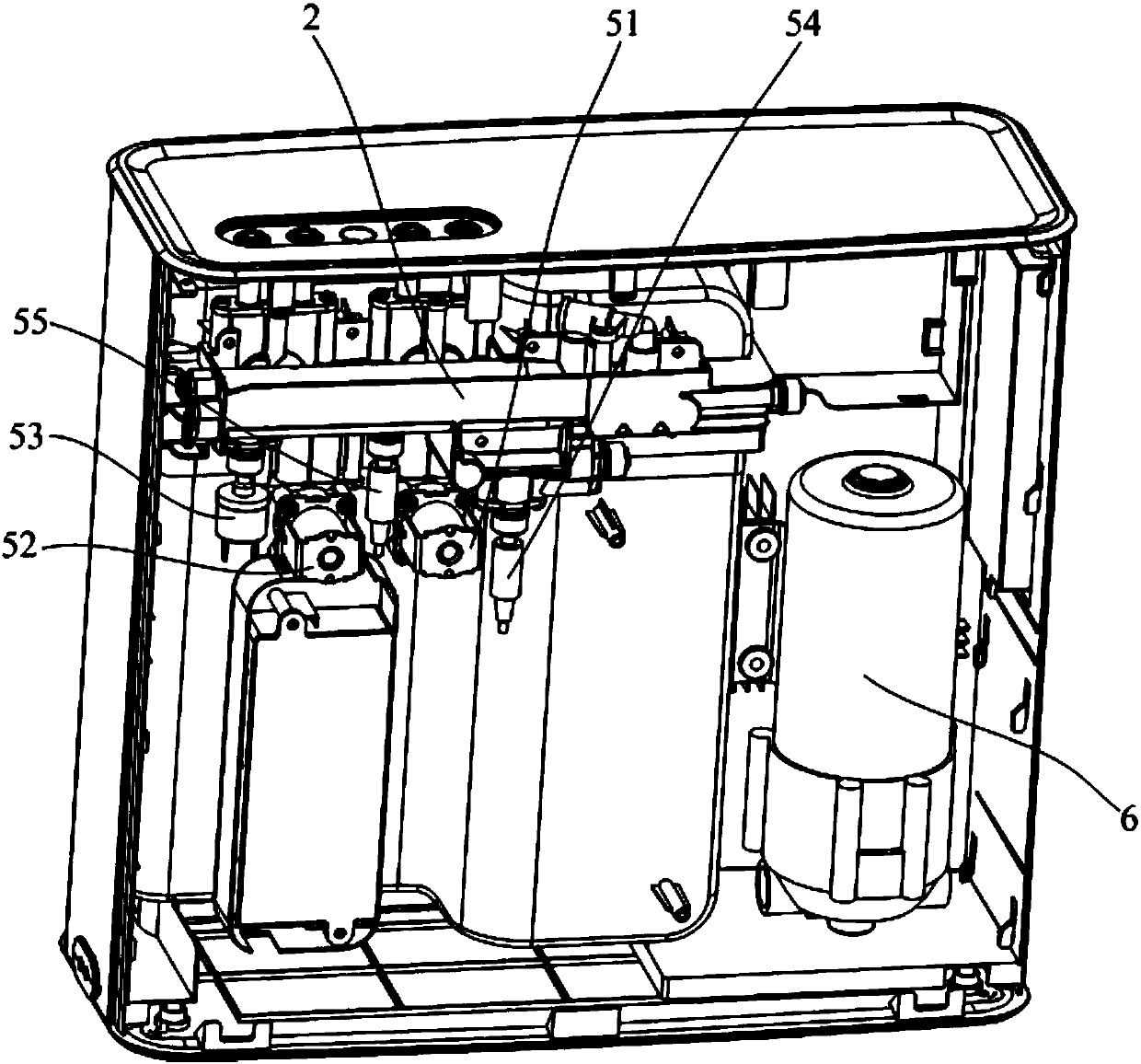

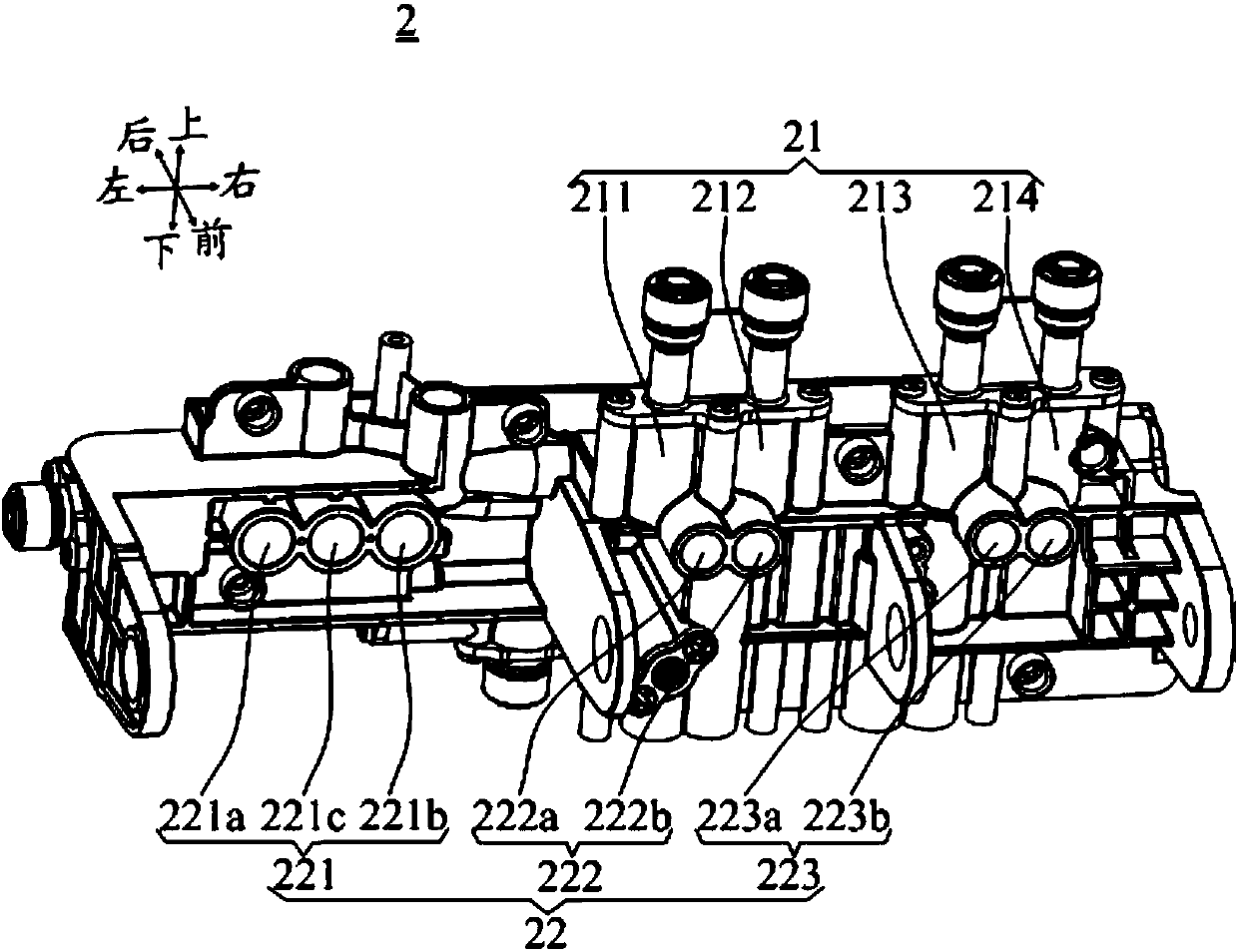

Integrated water path member and water purifier

ActiveCN107902773ALow mass production costRealize the assemblyGeneral water supply conservationTreatment involving filtrationEnvironmental engineeringControl valves

The invention discloses an integrated water path member and a water purifier. The integrated water path member comprises a member body, wherein a plurality of filtration core straight flow channels capable of extending forward and a plurality of control valve straight flow channels capable of extending downward are formed in the member body, the filtration core straight flow channels are used forconnecting the filtration core of a water purifier, and the control valve straight flow channels are used for connecting the control valve of the water purifier. With the technical scheme of the present invention, the assembly efficiency of the water purifier can be improved.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

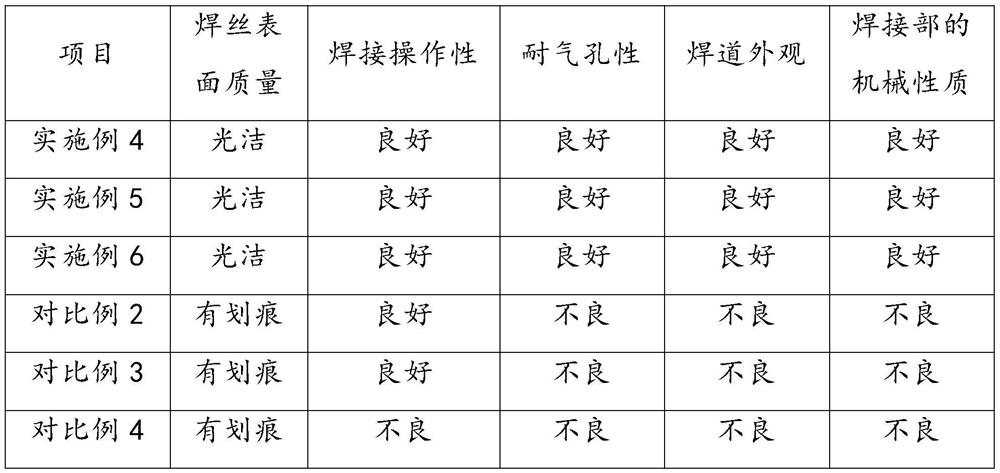

Preparation method of nickel-based alloy welding wire

ActiveCN113953716AReduce corrosionExtended service lifeWelding/cutting media/materialsSoldering mediaOxidation resistantCorrosion

The invention relates to a preparation method of a nickel-based alloy welding wire, and belongs to the technical field of welding material preparation. The preparation method comprises the following steps that 1, alloy smelting is carried out, specifically, the alloy comprises the following components of C, Si, Cr, Ti, Nb, W, Al, Fe, Mn, MO and the balance Ni; 2, ingot casting is carried out; 3, hot forging cogging is carried out, specifically, the alloy ingot is put into a heating furnace to be heated, forging is carried out, and an alloy blank is obtained; 4, hot rolling annealing is conducted, specifically, the alloy blank is hot-rolled into a disc round wire; 5, acid pickling, coping and cold drawing are conducted; 6, dehydrogenation annealing is conducted; and 7, auxiliary coating is carried out, specifically, the welding wire penetrates through a container containing auxiliaries, drying is carried out at the temperature of 18-30 DEG C, and the nickel-based alloy welding wire is obtained. According to the method, through the steps of metal raw material selection, alloy smelting, ingot casting, hot forging cogging, hot rolling annealing, acid pickling, coping, cold drawing, dehydrogenation annealing and auxiliary coating, the nickel alloy welding wire has good mechanical property, corrosion resistance and oxidation resistance.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

Heating cup body manufacturing method

ActiveCN109773361AAvoid poor solderingEasy to cleanCooking-vessel materialsWelding apparatusChromiumMelting point

The invention provides a heating cup body manufacturing method. The heating cup body manufacturing method comprises the steps that a heating device is welded to the outer surface of a metal inner cupthrough a welding medium; and a non-stick layer is sintered onto the inner surface of the metal inner cup. The melting point of the heating device and the melting point of the metal inner cup are higher than the melting point of the welding medium, and the melting point of the welding medium is higher than the sintering temperature of the non-stick layer. When the non-stick layer is sintered ontoa heating cup body, the welding medium is not melted, thus, it is ensured that the heating device is firmly welded to the metal inner cup, and the problem that heating device welding is poor or the heating device is disengaged after welding is solved; and in addition, manganese, chromium and other elements contained in stainless steel do not seep into slurry, and the edible safety of the slurry iseffectively ensured.

Owner:JOYOUNG CO LTD

Duplex metal welding rod and manufacturing method thereof

InactiveCN104889590AAutomatic disengagementAvoid residueWelding/cutting media/materialsSoldering mediaMolten stateBond interface

The invention discloses a duplex metal welding rod and a manufacturing method thereof. The duplex metal welding rod comprises a metal core wire and a coating, the metal core wire comprises an operating part and a clamping part which are fixedly connected, the diameter of the operating part is the same as that of the clamping part, the operating part is made from iron alloy wires, the clamping part is made from aluminum magnesium alloy wires, and the atomic ratio of aluminum and magnesium in the aluminum magnesium alloy wires is 3:2. The method comprises the steps of welding the operating part and the clamping part to form the core wire in a friction way, and coating the coating on the outer surface of the core wire. According to the duplex metal welding rod provided by the invention, the clamping part and a welded joint can be automatically separated; furthermore, the aluminum magnesium alloy is served as the clamping part, on one aspect, the clamping end planes of soldering pliers have good conductivities; meanwhile, spinel phase welding slag of MgO (Magnesium Oxide) and Al2O3 (Aluminum Oxide) is formed on a bonding interface of the clamping part when the total operating part is molten in the welding process, and the duplex metal welding rod has a stronger separating capacity from the welded joint of a molten state.

Owner:赵兰

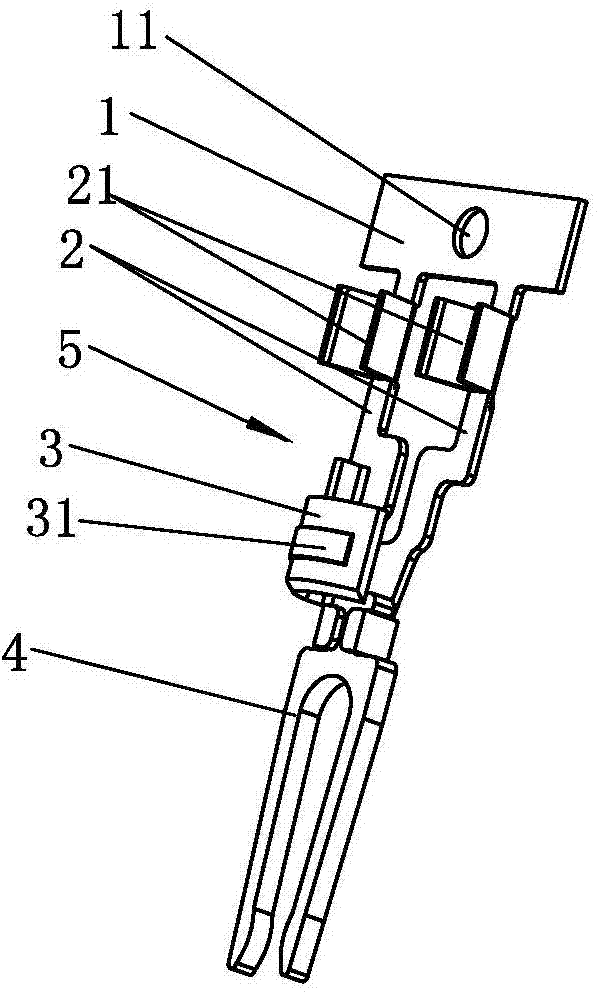

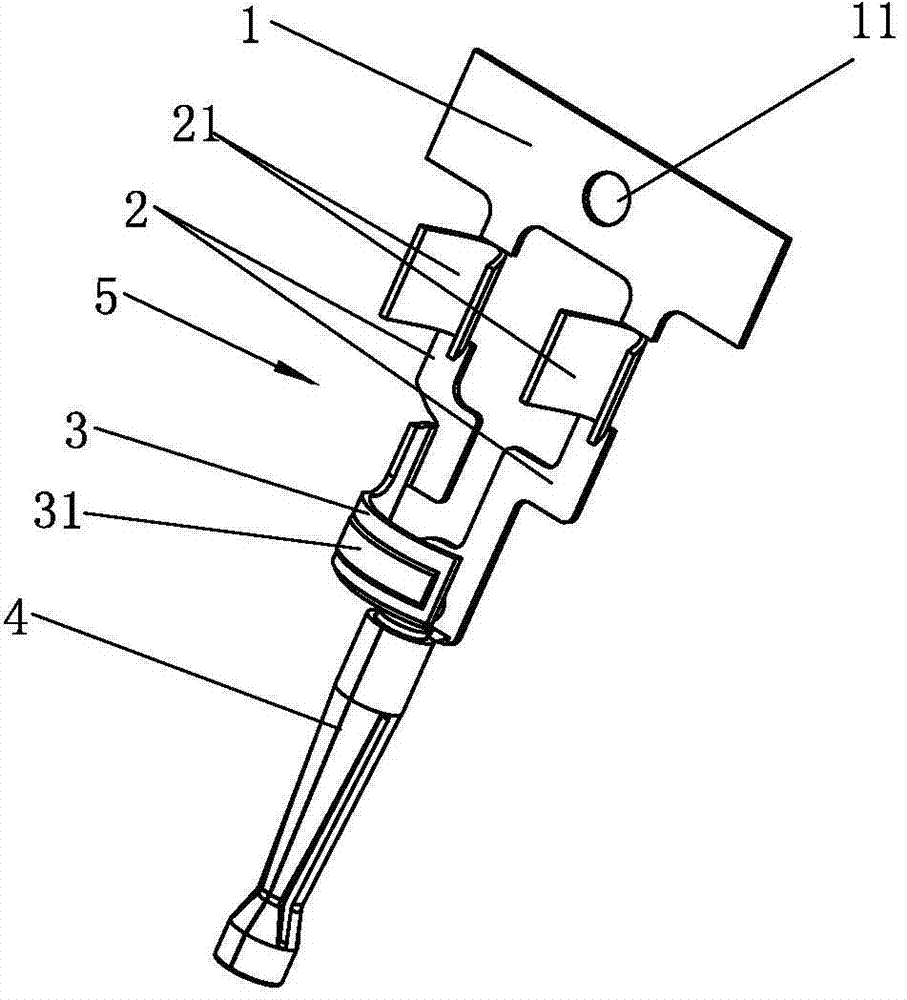

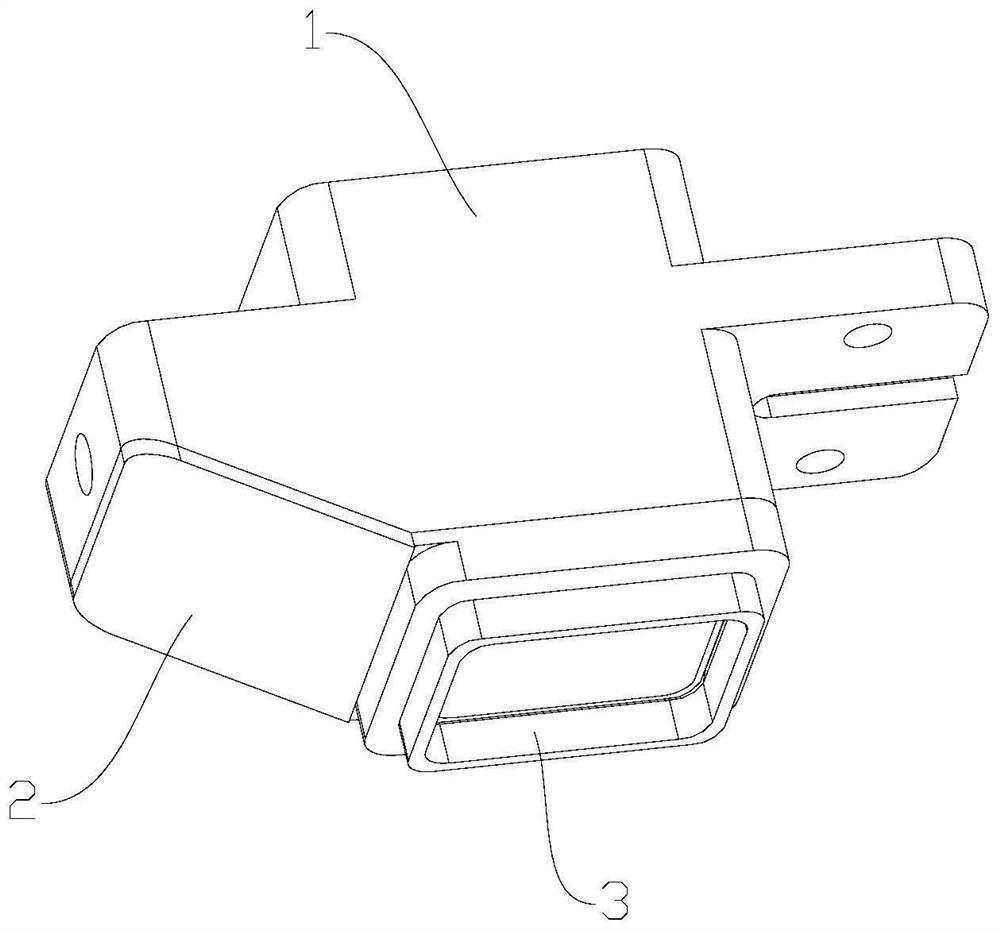

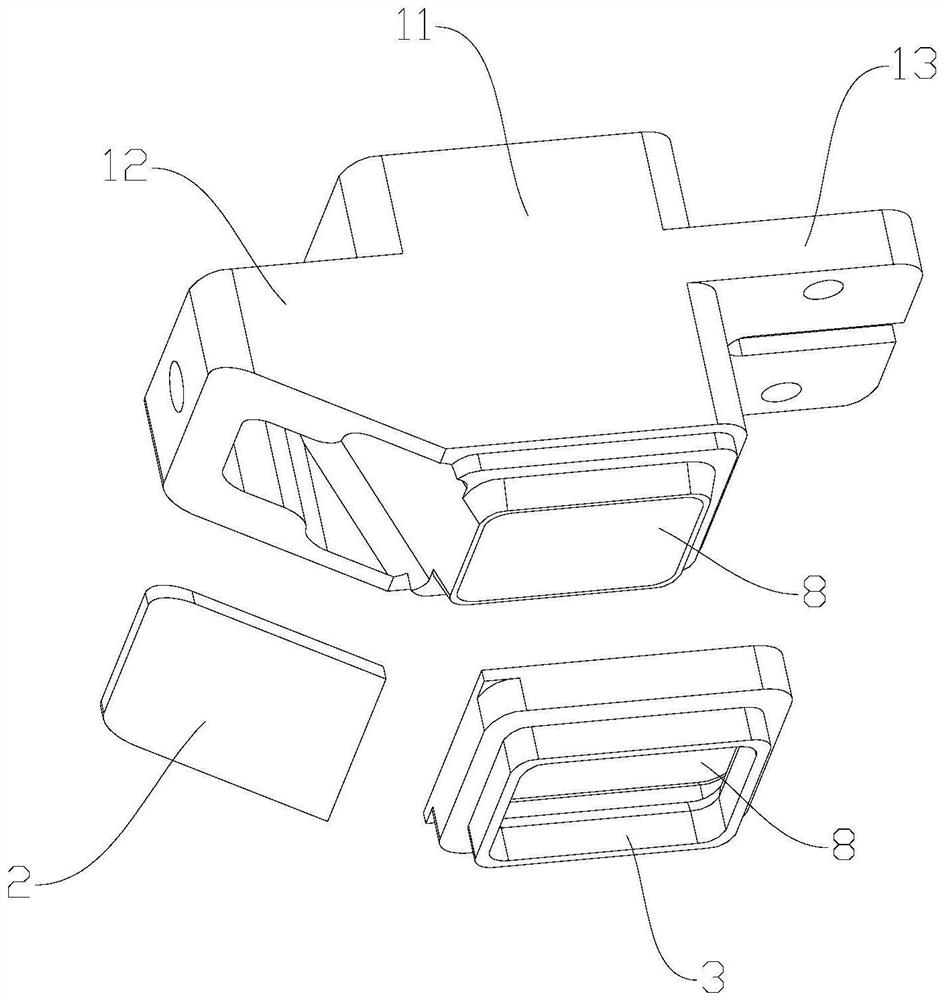

DC plug metal contact and metal contact flat cable capable of automatically crimping

InactiveCN103794901AClosely connectedAvoid poor solderingContact member manufacturingCoupling contact membersMetalElectrical and Electronics engineering

The invention relates to the technical field of a DC plug, and particularly relates to a DC plug metal contact and a metal contact flat cable capable of automatically crimping. According to the DC plug metal contact, a half-ring-shaped contact plate and an inner elastic contact plate are connected with transverse connect plates through two connect plates, the connect plates are provided with wire riveting positions near the position of the transverseconnect plates, when the DC plug is produced, an interpolation core formed by the metal contact is arranged inside an insulation coat shell in an inserting mode, and the half-ring-shaped contact plate is in contact with a bare contact part of the coat shell. Two wires which are required to be connected are crimped on the riveting positions of the connect plates of the half-ring-shaped contact plate and the inner elastic contact respectively through an automatic crimping machine, and the two wires are cut on the transverseconnect plates, so that the tight connection is assured, quality problem caused by traditionally welding is avoided, and production efficiency is improved. When a DC plug flat cable is formed by a whole chain of transverse connect plates, the transverse connect plates can be formed into a tray and can be arranged on the crimping machine to automatically crimp the wires, and work efficiency is improved.

Owner:东莞市中普电子科技有限公司

Copper clad welding rod and manufacturing method thereof

InactiveCN104889607AAvoid residueImprove conductivityWelding/cutting media/materialsSoldering mediaCopper platingRare earth

The invention discloses a copper clad welding rod and a manufacturing method thereof, wherein the copper clad welding rod comprises a metal core and a welding flux covering; the metal core comprises a working part and a holding part that are fixedly connected with each other; the welding flux covering is covered outside the working part; the working part is an iron alloy wire; and the holding part is a copper-plated aluminum wire; the length ratio between the holding part and the working part is 1:7-8; and the welding flux covering comprises the following components: 20-25 parts by weight of albite, 10-12 parts by weight of potassium carbonate, 6-10 parts by weight of calcium carbonate, 20-25 parts by weight of sodium silicate, 1-3 parts by weight of nanometer titanium dioxide, 2-3 parts by weight of nanometer ferric oxide, 1-1.5 parts by weight of manganese dioxide, 0.5-1 part by weight of rare earth lanthanum, 8-12 parts by weight of kaolin, and 6-10 parts by weight of Zuoyuntu (a raw material for electroceramics originating in Zuoyun County, Shanxi Province, China). The method comprises the steps of frictionally welding the working part with the holding part, and then coating the welding flux covering. By employing the contact interface design of the working part and the holding part of the welding rod, and utilizing the different characteristics of the metal and the welding flux covering, automatically releasing the welding rod head is achieved when the welding rod is about to run out, thereby thoroughly avoiding the residual of the welding rod head.

Owner:赵兰

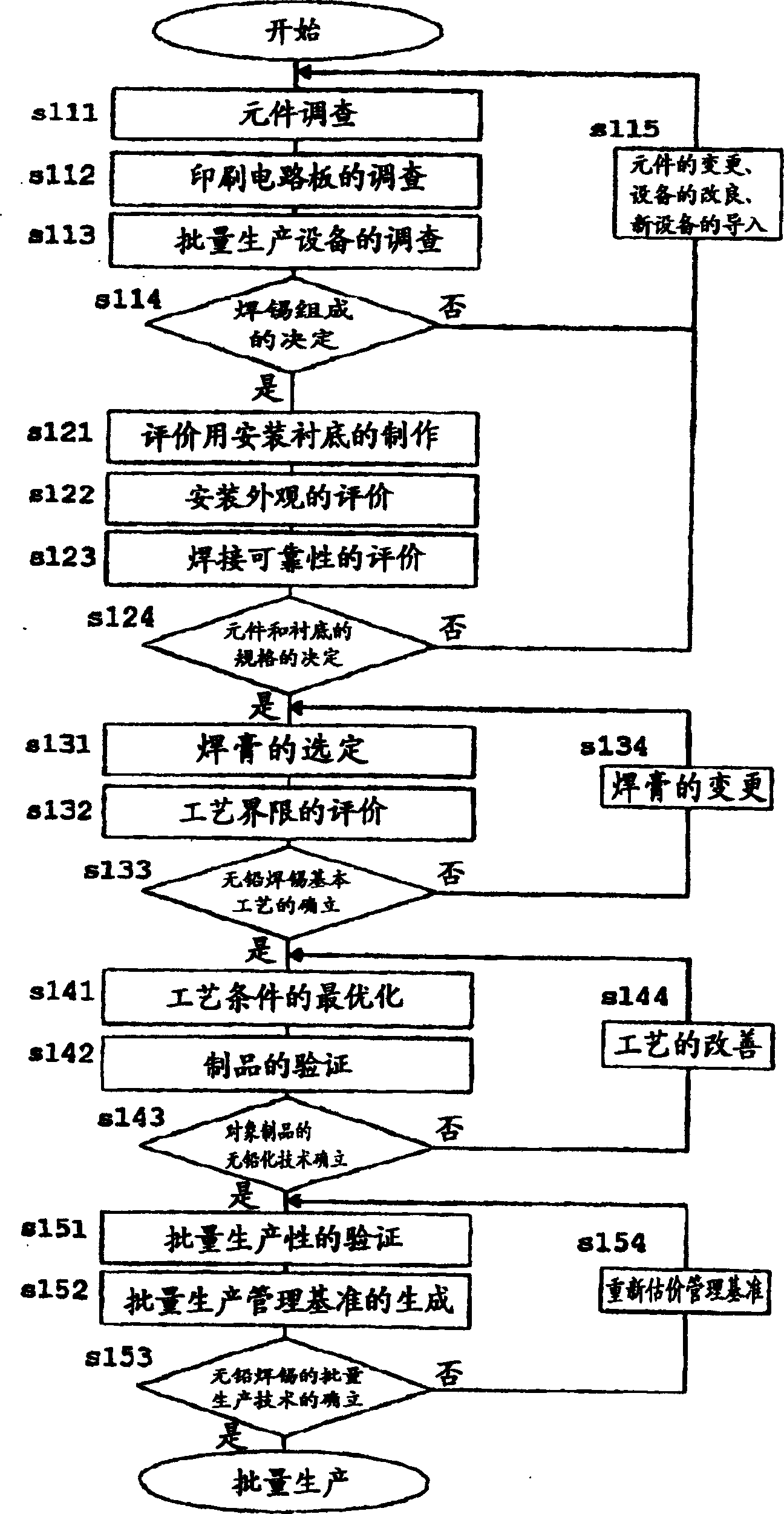

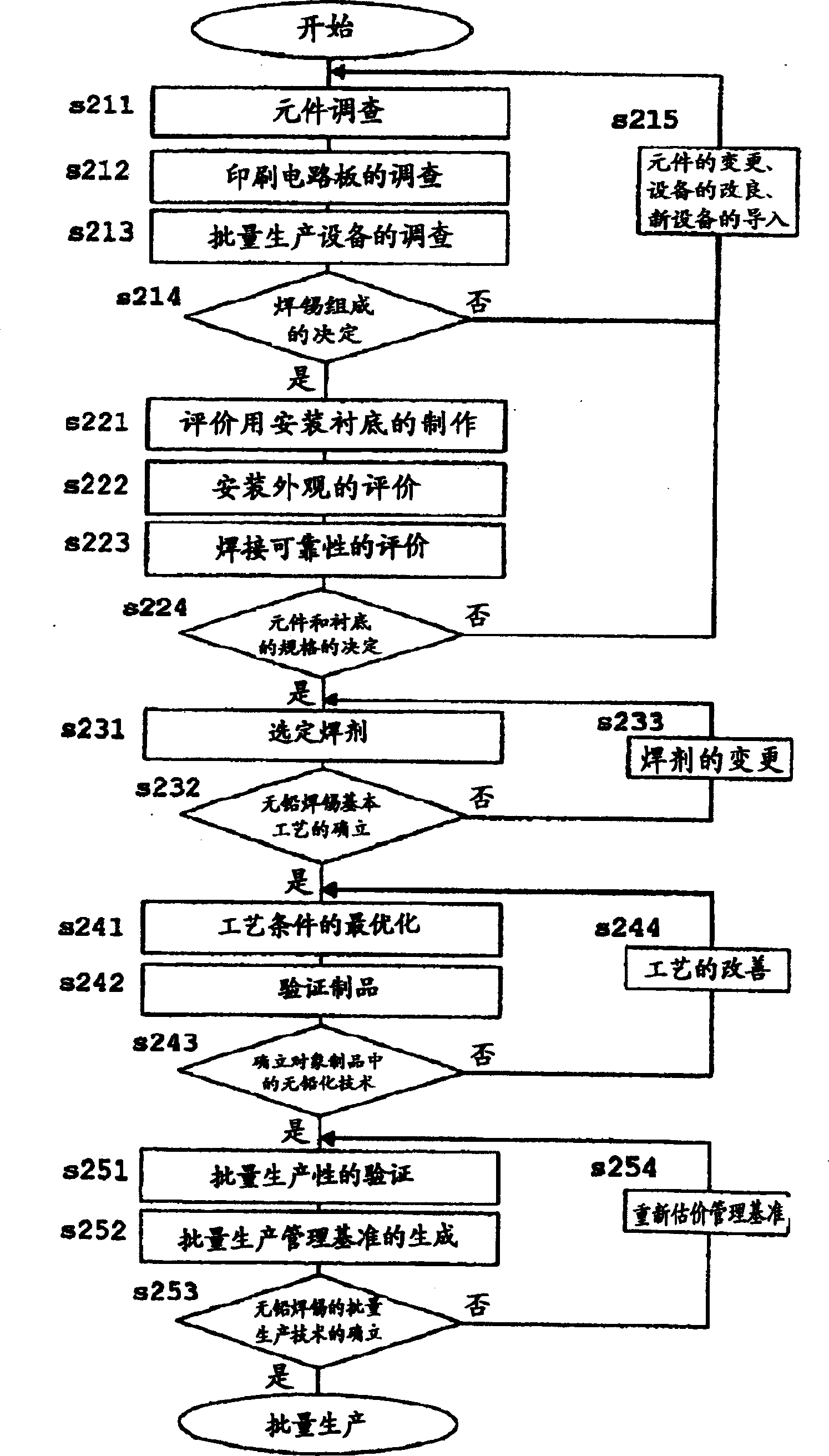

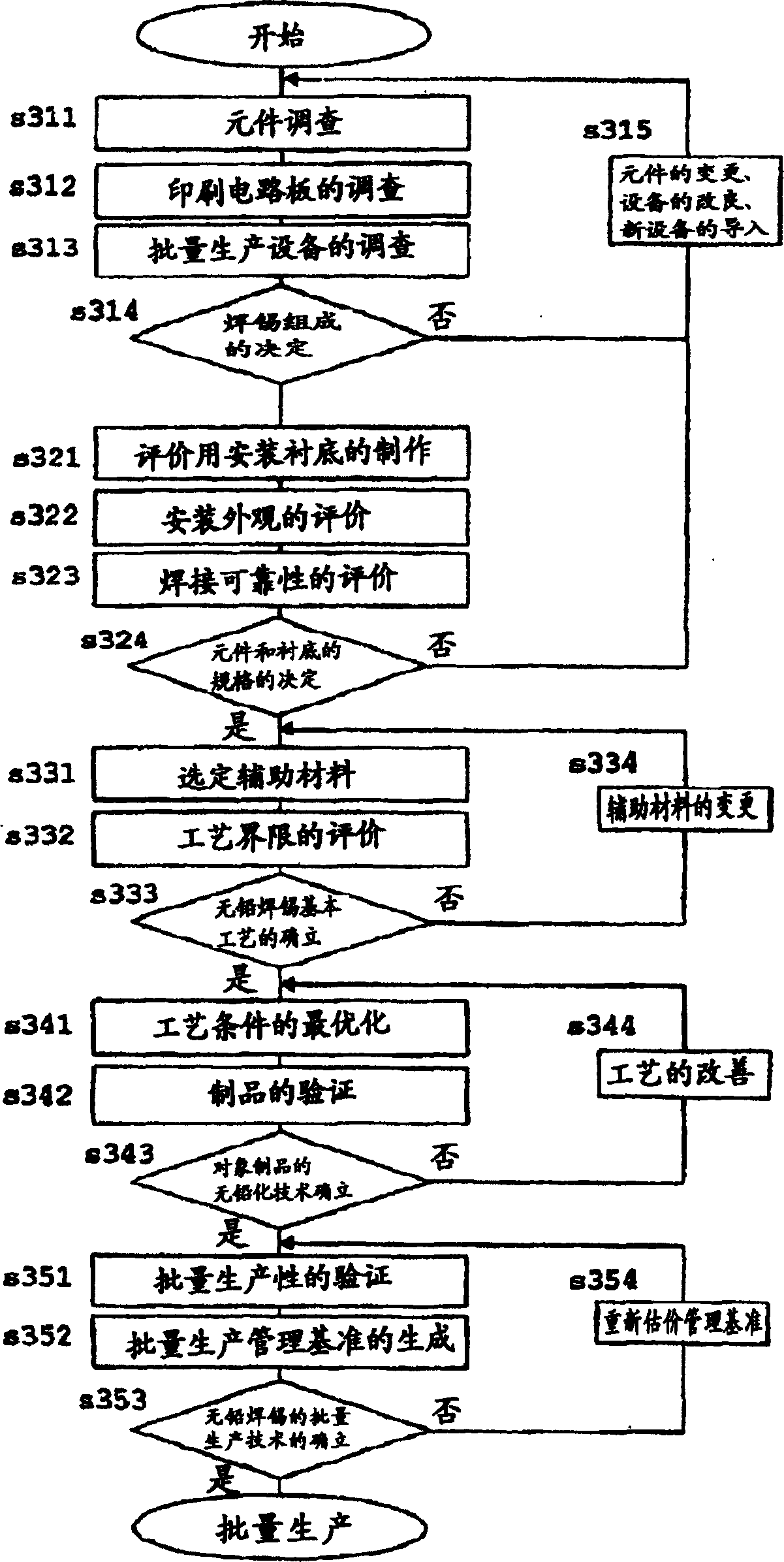

Electronic circuit installation wiring substrate manufacturing method based on lead-free soldering tin

InactiveCN1505460AImprove yieldAvoid poor solderingPrinted circuit assemblingInspection/indentification of circuitsProcess conditionsSolder paste

Provided is an electronic circuit installation wiring substrate manufacturing method based on lead-free soldering tin for preventing a decrease in yield due to a defect of soldering. This manufacturing method includes a processes for investigating mounted components, investigating printed boards, investigating mass-producing facilities, determining the composition of lead-free solder according to information on them, selecting paste and flux, optimizing process conditions, judging whether or not the process conditions are practical according to the evaluation obtained through the processes; optimizing the temperature profile of soldering, verifying products, examining whether or not a solder defect is caused and judging whether or not the technique is proper as a lead-free technique, verifying mass-productivity, generating and confirming mass-production management standard, and judging whether a mass-production technique has been established in those processes.

Owner:KK TOSHIBA

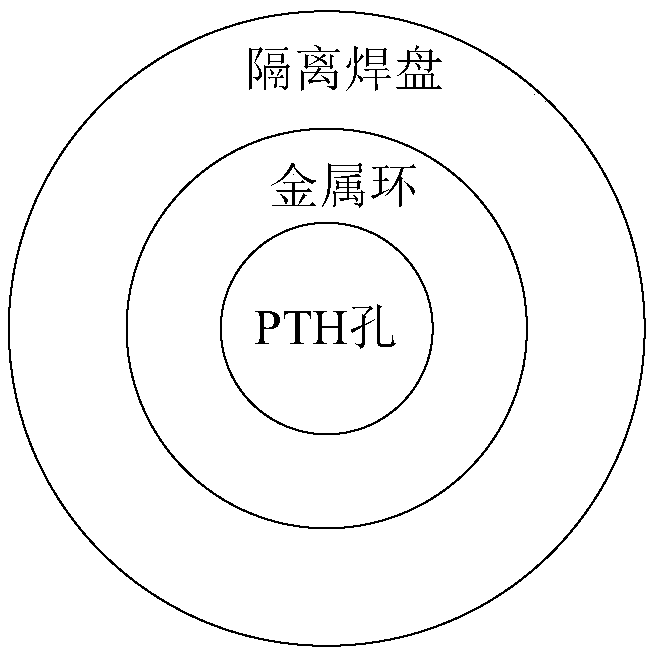

Automatic mounting and tin block addition-based through hole reflow soldering

InactiveCN108289389AImprove reliabilityAvoid poor solderingPrinted circuit assemblingDip solderingEngineering

The invention relates to the design field of a circuit, and particularly relates to an automatic mounting and tin block addition-based through hole reflow soldering. By applying automatic mounting andtin block addition-based through hole reflow soldering, a tin block material is loaded by a braided band, so that automatic material taking and tin block mounting and adding are realized; and the problems of less tin and poor soldering caused by the generated tin balls in the through hole reflow soldering are solved, reliability of through hole reflow soldering is improved, the processing qualityof a PCBA board is improved, the repair cost in manpower tin-supplementing soldering is lowered, and the hidden risk of short circuit caused by tin ball residue is eliminated.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

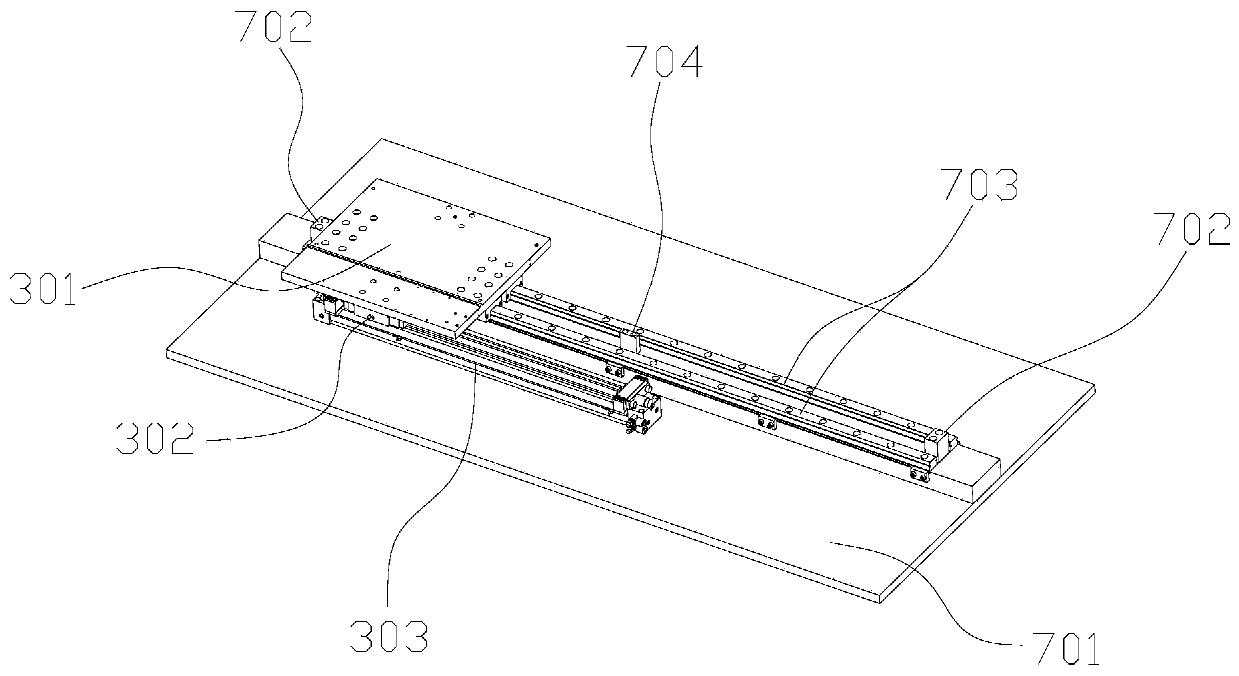

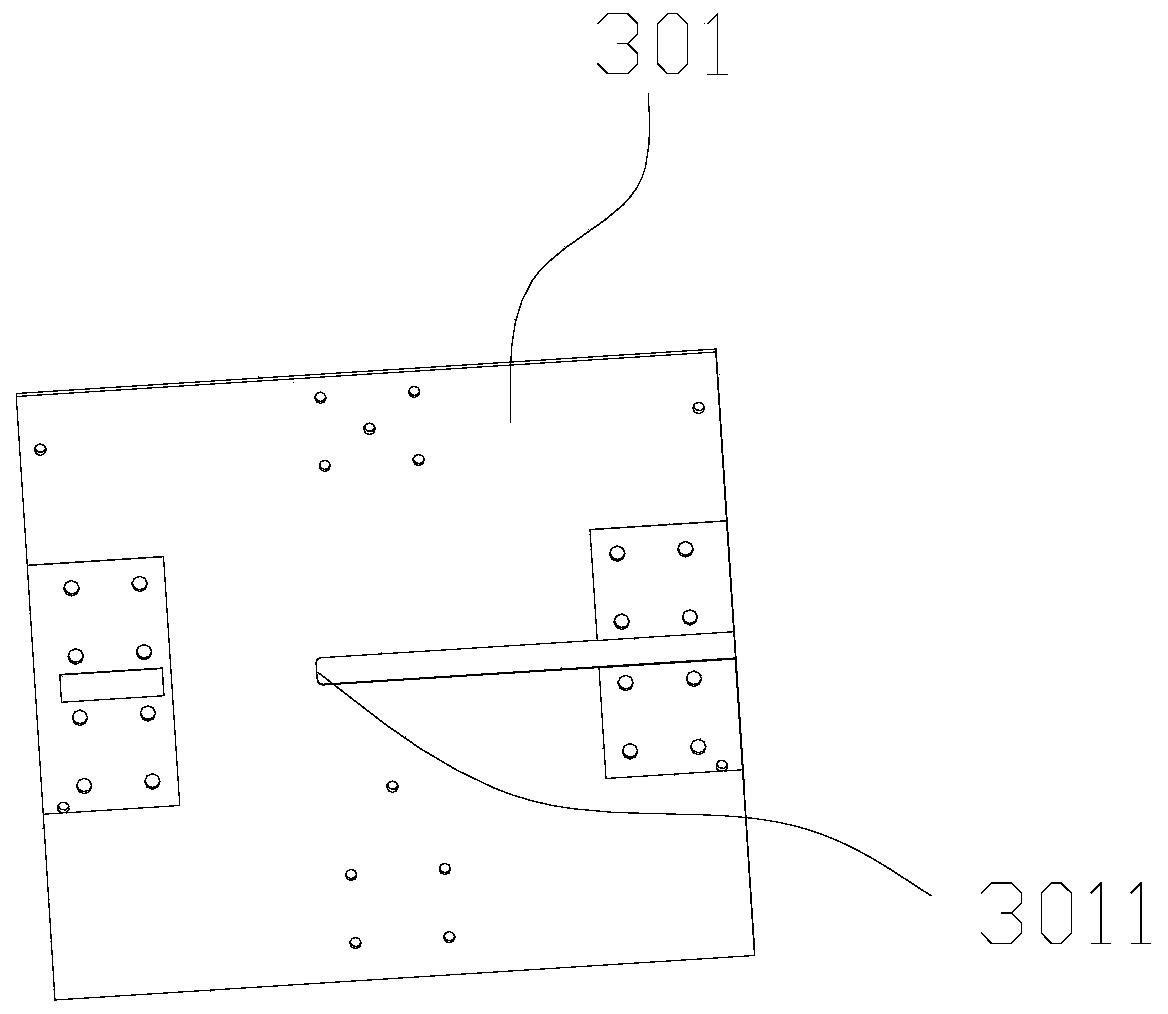

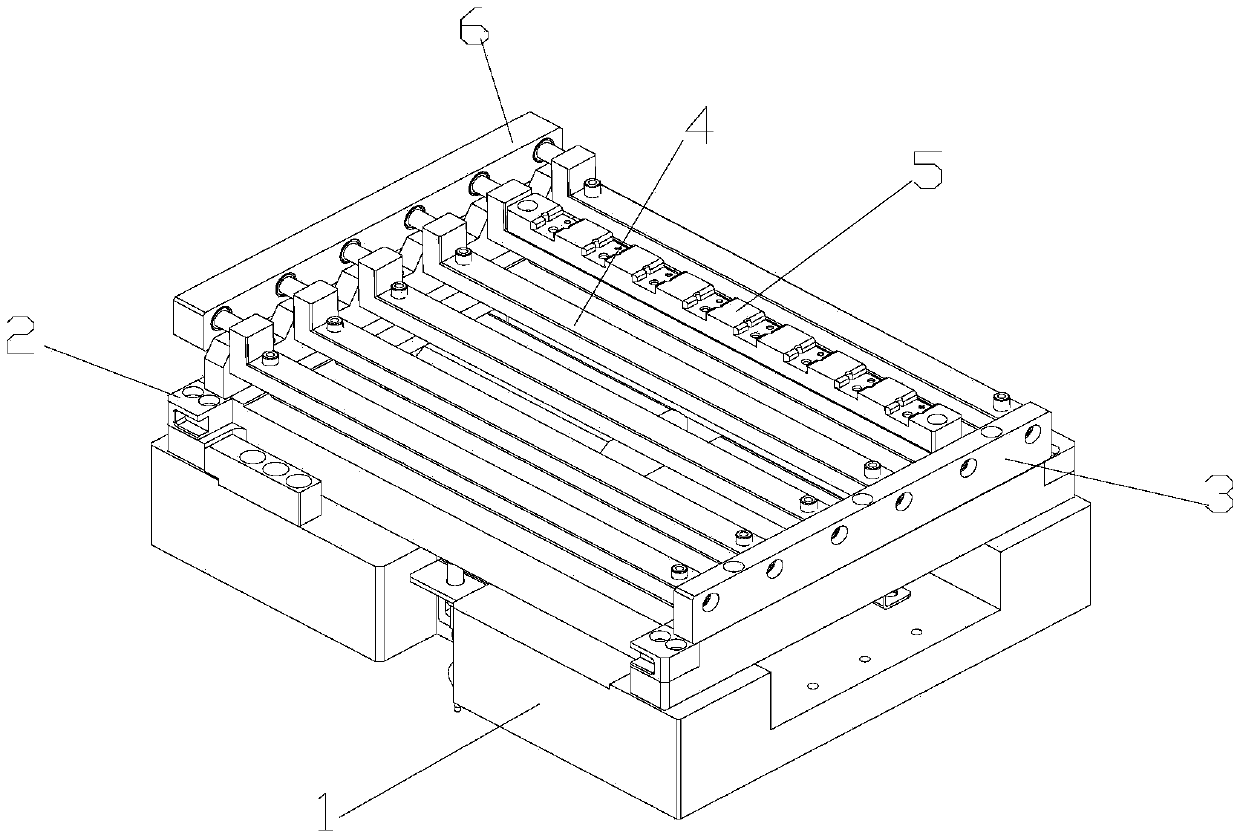

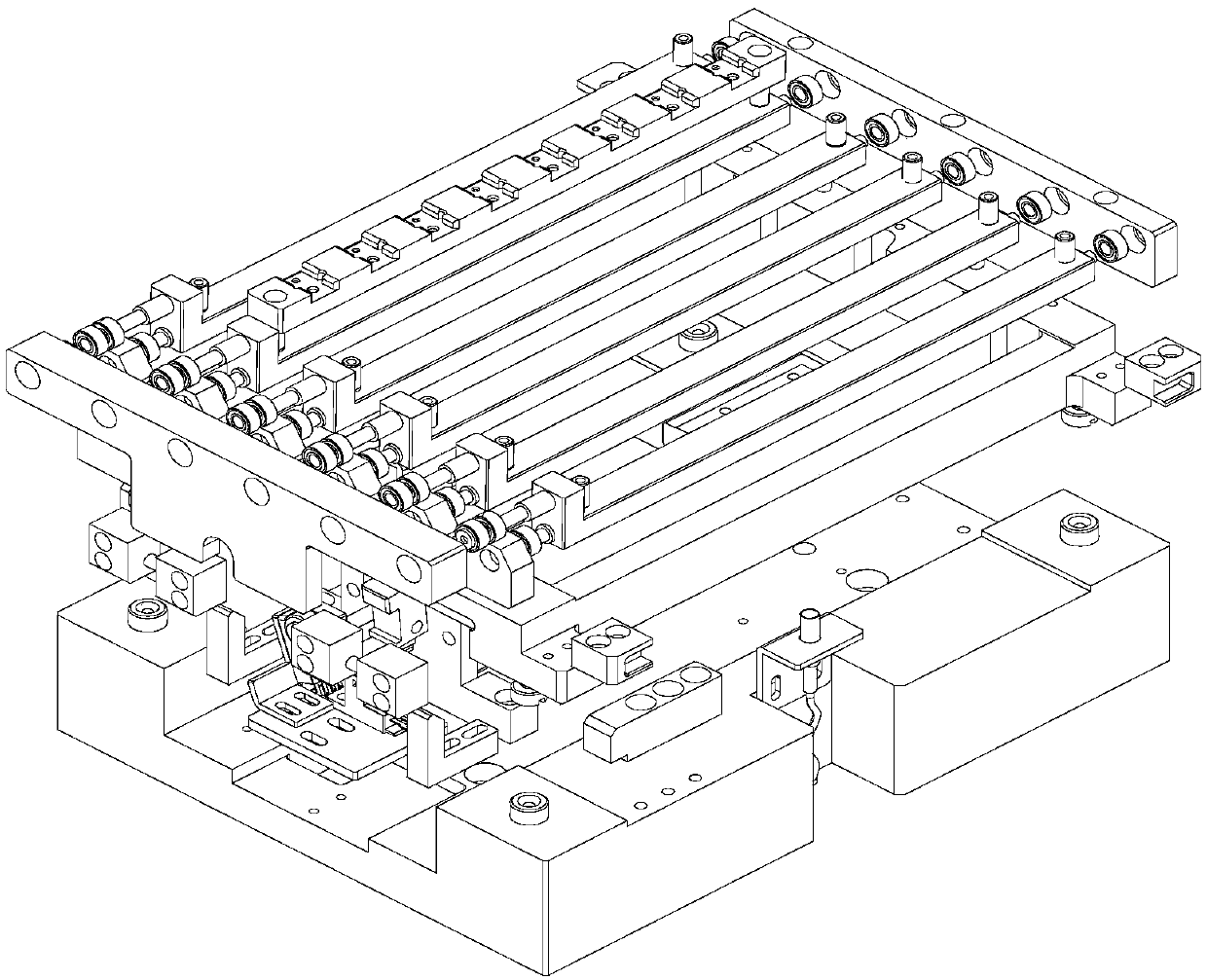

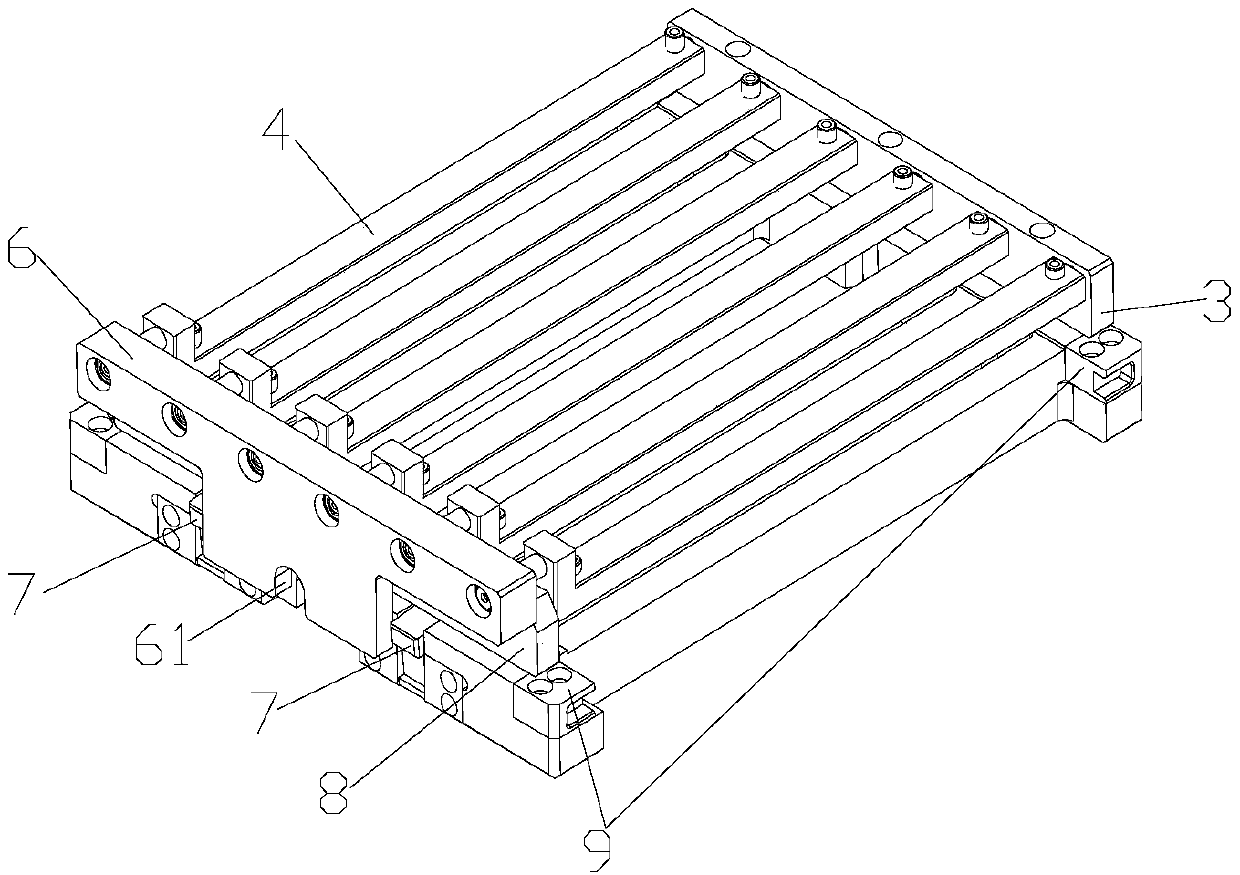

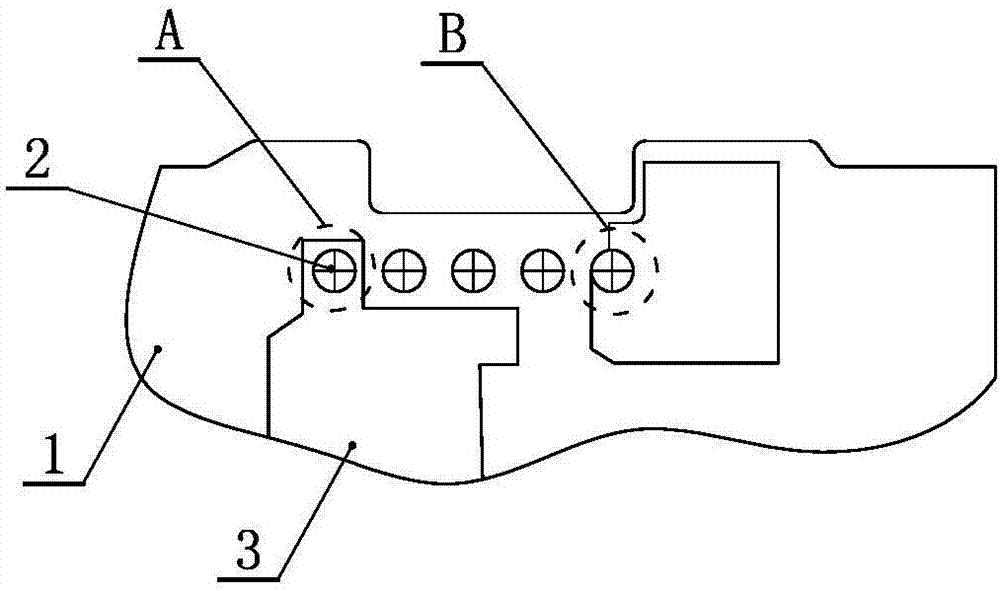

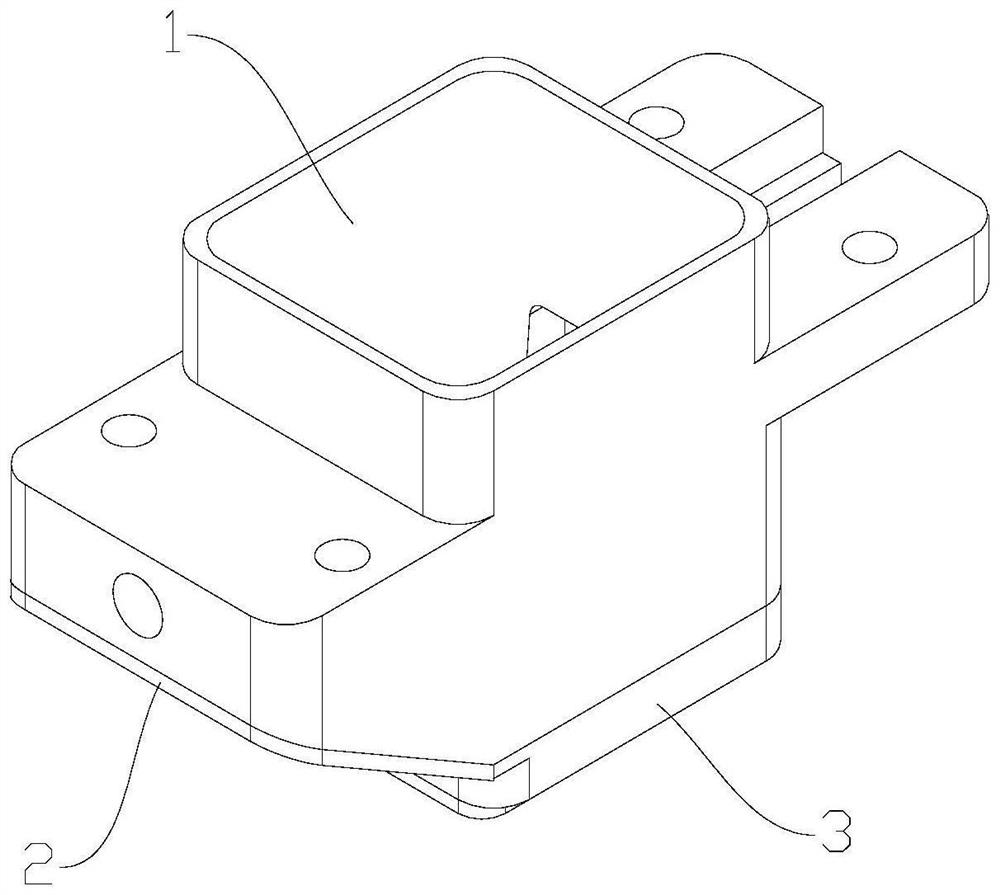

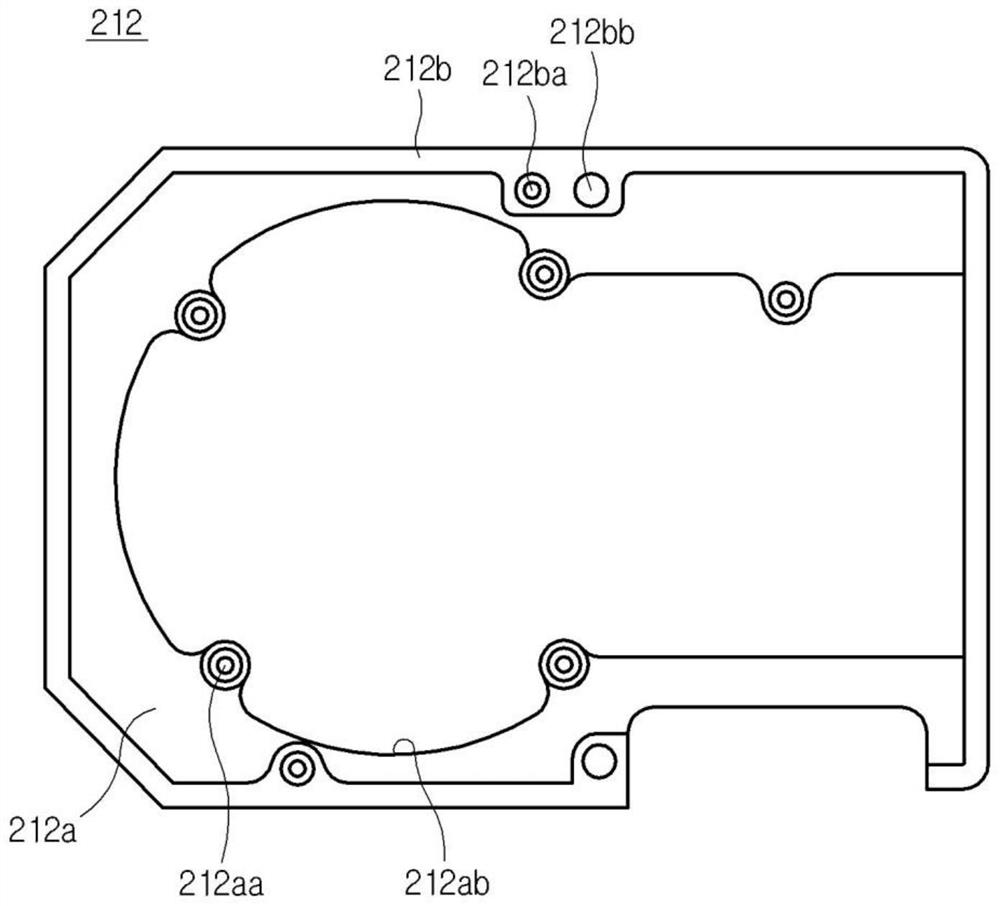

Mobile phone camera module welding and fixing device and welding fixing method thereof

PendingCN109648243AAvoid poor solderingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDrive motor

The invention discloses a mobile phone camera module welding and fixing device and a welding and fixing method thereof. The mobile phone camera module welding and fixing device comprises a base and atray mechanism connected with the base and used for fixing the camera module before welding, the tray mechanism comprises a tray support and multiple fixing strips capable of synchronously rotating, two ends of the fixing strips are rotatably connected with the tray support, a transmission part enabling the fixing strips to synchronously rotate is arranged at the same ends and is provided with anopening, and the opening is matched with an eccentric wheel or swing arm connected with a driving motor. During use, through the transmission part, all modules fixed to the fixing strips synchronouslyrotate by the specific angle for welding, after welding, the modules are taken out. Due to the fact that the fixing device enables the modules to synchronously rotate by the same angle, as long as during setting, the module fixing angles are adjusted, it must be ensured that the deviation angles of modules at the welding station are same, poor welding caused by different angles can be avoided, and the welding efficiency is improved.

Owner:SHENZHEN ANEWBEST ELECTRONICS TECH

Battery connector for solving poor welding, and manufacturing method thereof

InactiveCN107172811AReduce heat gainGood tinning effectPrinted circuit assemblingLine/current collector detailsCopper platingEngineering

The invention discloses a battery connector for solving poor welding, and a manufacturing method thereof. The battery connector comprises a PCB, wherein copper foil is arranged between Pins and the PCB, the copper foil outside Pin jacks is line-shaped, one end of the line-shaped copper foil is in contact with each Pin, and the rest part of the copper foil is attached to and fixed on the PCB. The manufacturing method comprises the steps of: S1, drilling through holes / blind holes in the PCB, wherein part of the through holes serve as the Pin jacks; S2, plating copper to form in-hole copper foil; S3, plating copper to form outer-hole copper foil; S4, and inserting the Pins into the Pin jacks subjected to copper plating. According to the battery connector and the manufacturing method thereof, the area of the copper foil is reduced while other parts remain unchanged, and the original surface-type copper foil is changed into the line-shaped copper foil, thus the reduction of heat absorbed by the cooper foil in a welding region is realized, the tin soldering effect is improved, and the welding quality is ensured. That is, the large copper foil area in the welding region is reduced to decrease the heat absorbed by the cooper foil, the absorption ability of the copper foil is decreased when the area of the copper foil is reduced, and the heat dissipation of the Pins welded on the connector is slowed down, thereby achieving the effect of satisfying the tin soldering requirement.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Sealing cell

ActiveCN101079475BEasy to weldPrevent the decrease of welding strengthFinal product manufactureSecondary cellsEngineeringElectrolyte

The present invention relates to a sealed battery, which reduces jointing badness and can seal sealed body to battery case. After injecting electrolyte into battery case (6) through injecting hole (16), to seal the injecting hole (16) through plugging up the injecting hole (16) using sealed pin (17) and joint the sealed pin (17) around the injecting hole (16). The sealed body (17) is made from metal envelope material of aluminum layer (25) and nickel layer (26), the aluminum layer (25) sets on the side of the battery case (6), and the margin part (25a) of the aluminum layer (25)is more extruding towards the external lateral of the sealed body (17) than the one of the nickel layer (26), and is jointed on the border of the injecting hole (16) using laser.

Owner:MAXELL HLDG LTD

Automatic control method and device of PCB layout

ActiveCN109600938AAvoid poor solderingLimit the number of connection layersComputer designed circuitsElectrical connection printed elementsAutomatic controlElectricity

The invention discloses an automatic control method and device of printed circuit board PCB layout. The method comprises the following steps: in the PCB layout process, when a new conducting layer isincreased, for a predetermined PTH hole, judging whether the amount of conducting layer currently connected by a PTH hole has reached the preset maximum amount of layer, if the amount of conducting layer currently connected by a PTH hole has reached the preset maximum amount of layer, electrically isolating the PTH hole from the newly added conducting layer. Through the scheme disclosed by the invention, the amount of connecting layer of the PTH hole can be accurately and efficiently restricted, thereby avoiding the problem that the tinning is bad due to overmuch amount of connecting layer ofthe PTH hole.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

A precision welding method and device for a power battery

ActiveCN110814609BReduce mistakesPrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesPower batteryElectrical and Electronics engineering

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Pressing cylinder structure and laser welding equipment

The invention belongs to the technical field of laser welding, and relates to a pressing cylinder structure and laser welding equipment. The laser welding device is applied to laser welding of a power battery module and comprises a first pressing cylinder, a cover plate and a second pressing cylinder. The second pressing cylinder is arranged at the bottom of the first pressing cylinder, an air inlet is formed in one side of the first pressing cylinder, the cover plate is arranged on the side, located on the air inlet, of the first pressing cylinder, and an air channel is formed among the first pressing cylinder, the cover plate and the second pressing cylinder. The air channel is communicated with the air inlet, air outlets are formed in the lower end of the first pressing cylinder and the lower end of the second pressing cylinder, the air inlet is used for blowing in protective gas, and the protective gas passes through the air channel and is blown out of the air outlets. The shielding gas can cover each welding area more uniformly, so that each welding area is protected more comprehensively, the situations that a welding object splashes and the surplus height of a welding seam is too high during welding are well reduced, the welding effect is improved to a great extent, and the welding object is more attractive after being welded.

Owner:深圳市大族锂电智能装备有限公司

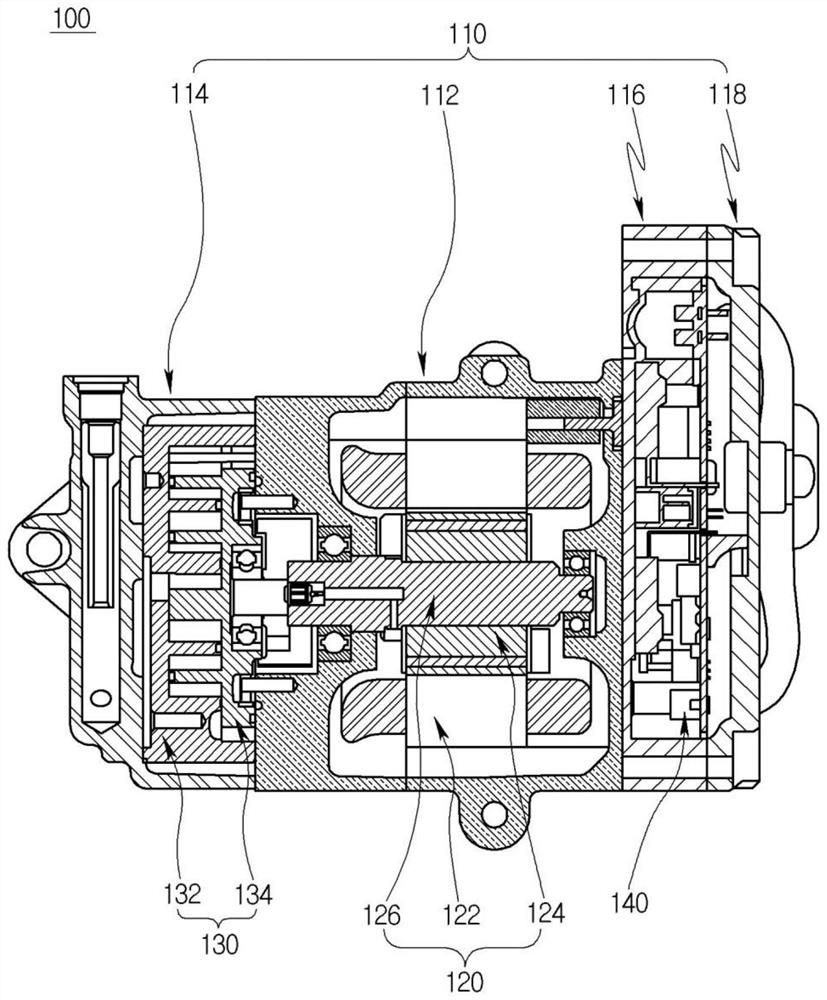

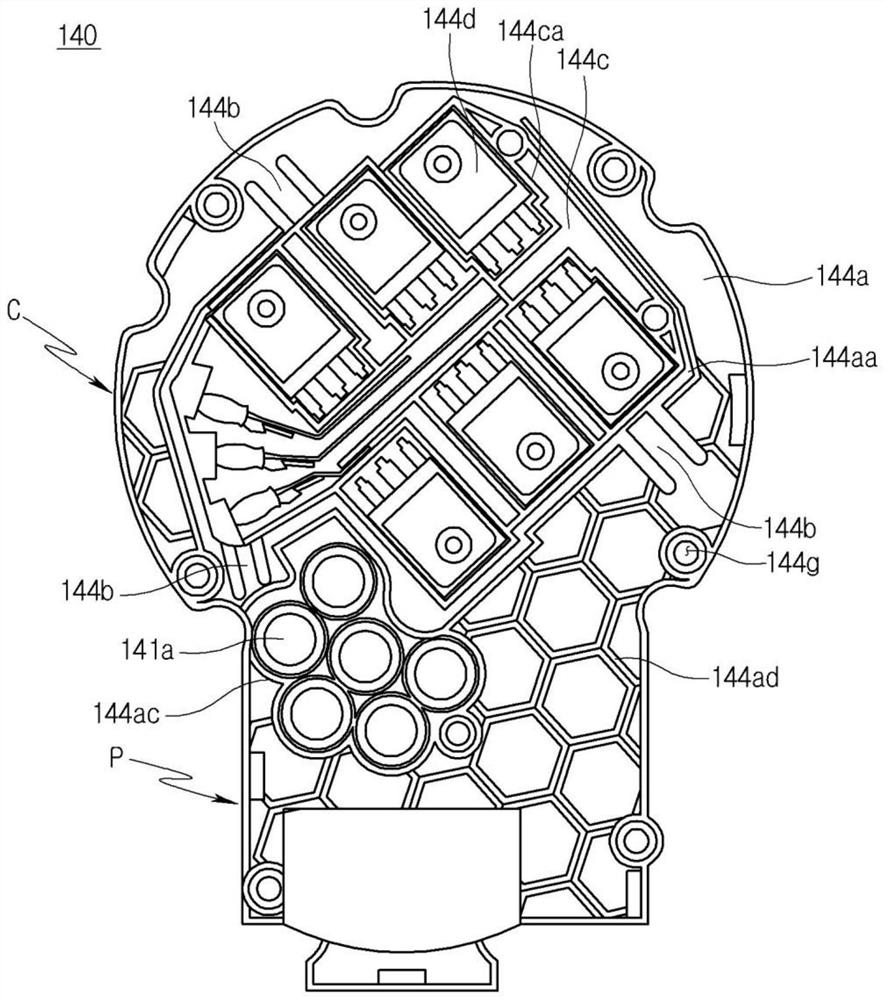

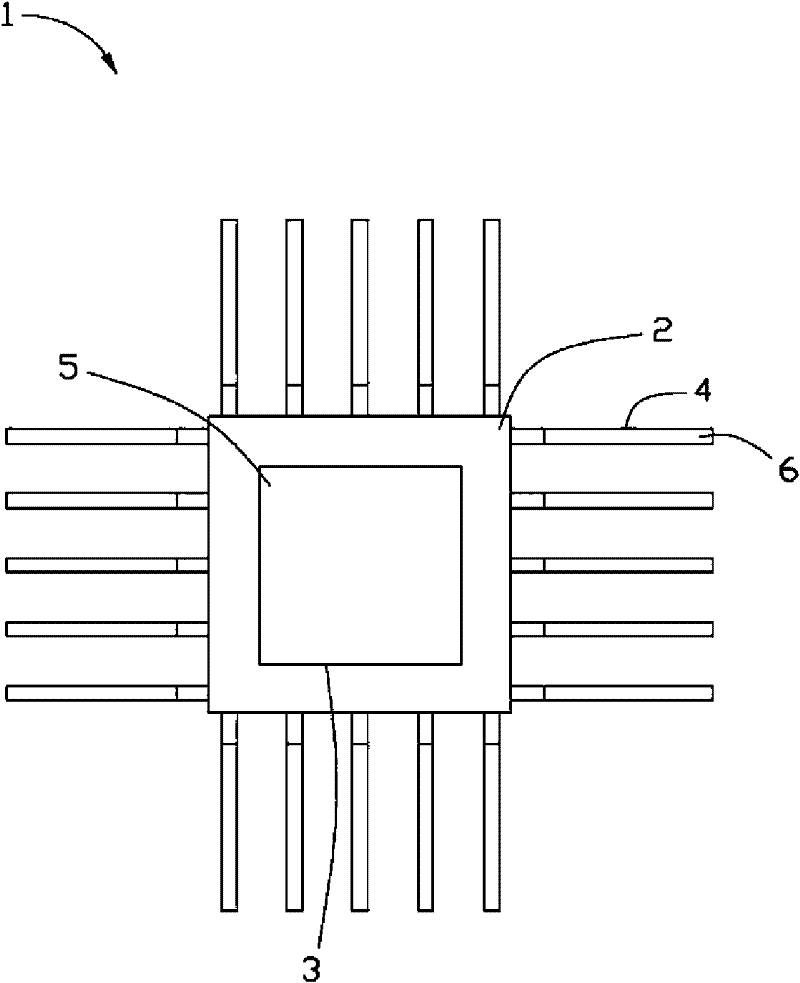

Electric compressor, inverter manufacturing apparatus and inverter manufacturing method

PendingCN114080504APrevent disengagementAvoid poor solderingRotary/oscillating piston combinations for elastic fluidsAssociation with control/drive circuitsThermodynamicsManufactured apparatus

The present invention relates to an electric compressor, an inverter manufacturing apparatus and an inverter manufacturing method. An inverter of an electric compressor comprises: a substrate having a plurality of elements mounted thereon; and a frame coupled to the substrate. The frame comprises: a support plate; a side plate portion protruding from the support plate toward the substrate; an array plate on which switching elements connecting to the substrate are arrayed; and a connecting bar for connecting the support plate and array plate. The inverter manufacturing apparatus comprises: a first dummy plate fixed to the frame; and a second dummy plate which is coupled to the first dummy plate, comes into contact with the switching elements, and fixes the plurality of elements and switching elements and dissipates the heat thereof. The inverter manufacturing method comprises the steps of: placing an inverter on the first dummy plate; fixing the plurality of elements and switching elements by coupling the second dummy plate to the first dummy plate, and connecting the switching elements to a heat dissipation plate of the second dummy plate; and soldering the plurality of elements. Therefore, a soldering defect and element damage can be prevented.

Owner:HANON SYST

Surface mount structure and circuit board with same

ActiveCN102056405BBlock flowImprove placement qualityElectrical connection printed elementsPrinted circuit non-printed electric components associationWire widthCurrent limiting

The invention provides a surface mount structure used for fixedly mounting an electronic element with a pin and a welding chassis onto a circuit board. The surface mount structure comprises a pad formed on the circuit board, wherein the pad comprises a first pad welded with the bottom surface of the pin, a second pad welded with the bottom surface of the welding chassis and a connecting wire for connecting the first pad and the second pad. The structure is characterized in that the area of the surface of the second pad, which is opposite to the bottom surface of the welding chassis, is largerthan the area of the surface of the first pad, which is opposite to the bottom surface of the pin; the space between the first pad and the second pad is smaller than 0.3mm; the connecting wire comprises a current-limiting part and a non-current-limiting part; the current-limiting part is connected with the first pad, and the non-current-limiting part is connected with the second pad; and the partial or overall wire width of the current-limiting part is smaller than the wire width of the non-current-limiting part.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com