Preparation method of nickel-based alloy welding wire

A nickel-based alloy and welding wire technology, which is applied in the field of nickel-based alloy welding wire preparation, can solve problems such as easy generation of hot cracks, adverse effects on mechanical properties of components, and poor thermal corrosion resistance of nickel-based alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

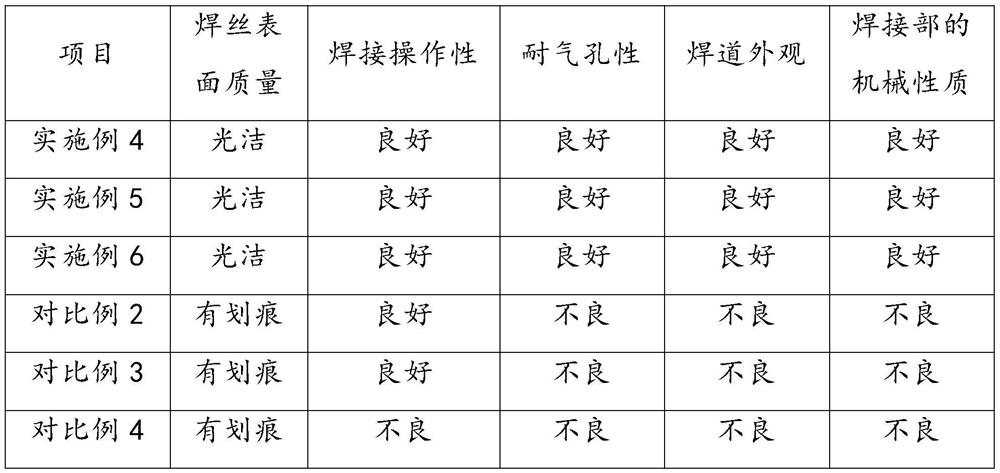

Examples

Embodiment 1

[0032] This embodiment provides a kind of auxiliary agent, is made by the following steps:

[0033] Step A1, prepare the following raw materials in parts by weight: 2.8 parts of phosphoric acid, 20 parts of rosin derivatives, 10 parts of diethylene glycol monobutyl ether, and 50 parts of polyethylene glycol;

[0034] Step A2: Put the raw materials in the above formula in a reaction kettle, heat up to 100°C for 10 minutes, then cool down to 65°C, stir and mix for 30 minutes, then cool down to room temperature, and grind 3 times to obtain additives.

[0035] Wherein, rosin derivative is made by following steps:

[0036] Step S1. Add 500g of masson pine rosin to the four-necked flask, and start to raise the temperature while introducing nitrogen. When the temperature rises to 180°C, add 131g of maleic anhydride in 5 times in equal amounts, with an interval of 5 minutes between each addition. After the addition, keep warm React for 4 hours, transfer to turpentine at 45°C while it...

Embodiment 2

[0041] This embodiment provides a kind of auxiliary agent, is made by the following steps:

[0042] Step A1, prepare the following raw materials in parts by weight: 3.0 parts of phosphoric acid, 23 parts of rosin derivatives, 12 parts of diethylene glycol monobutyl ether, and 55 parts of polyethylene glycol;

[0043] Step A2. Put the raw materials in the above formula in a reaction kettle, heat up to 100°C for 15 minutes, then cool down to 68°C, stir and mix for 32 minutes, then cool down to room temperature, and grind 4 times to obtain the additive.

[0044] Wherein, rosin derivative is made by following steps:

[0045] Step S1. Add 500g of masson pine rosin to the four-necked flask, and start to raise the temperature while introducing nitrogen. When the temperature rises to 180°C, add 132g of maleic anhydride in equal amounts in 5 times, with an interval of 5 minutes between each addition. After the addition, keep warm React for 4 hours, transfer it to turpentine oil at 48°...

Embodiment 3

[0050] This embodiment provides a kind of auxiliary agent, is made by the following steps:

[0051] Step A1, prepare the following raw materials in parts by weight: 3.2 parts of phosphoric acid, 25 parts of rosin derivatives, 18 parts of diethylene glycol monobutyl ether, and 60 parts of polyethylene glycol;

[0052] Step A2. Put the raw materials in the above formula in a reaction kettle, heat up to 100°C for 10-20 minutes, then cool down to 70°C, stir and mix for 35 minutes, then cool down to room temperature, and grind 5 times to obtain the auxiliary agent.

[0053] Wherein, rosin derivative is made by following steps:

[0054] Step S1. Add 500g of masson pine rosin to the four-necked flask, and start to raise the temperature while introducing nitrogen. When the temperature rises to 180°C, add 136g of maleic anhydride in equal amounts in 5 times, with an interval of 5 minutes between each addition, and keep warm after the addition React for 4 hours, transfer to turpentine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com