Electronic circuit installation wiring substrate manufacturing method based on lead-free soldering tin

A wiring substrate and lead-free solder technology are applied in the field of manufacturing wiring substrates for electronic circuit installation based on lead-free solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

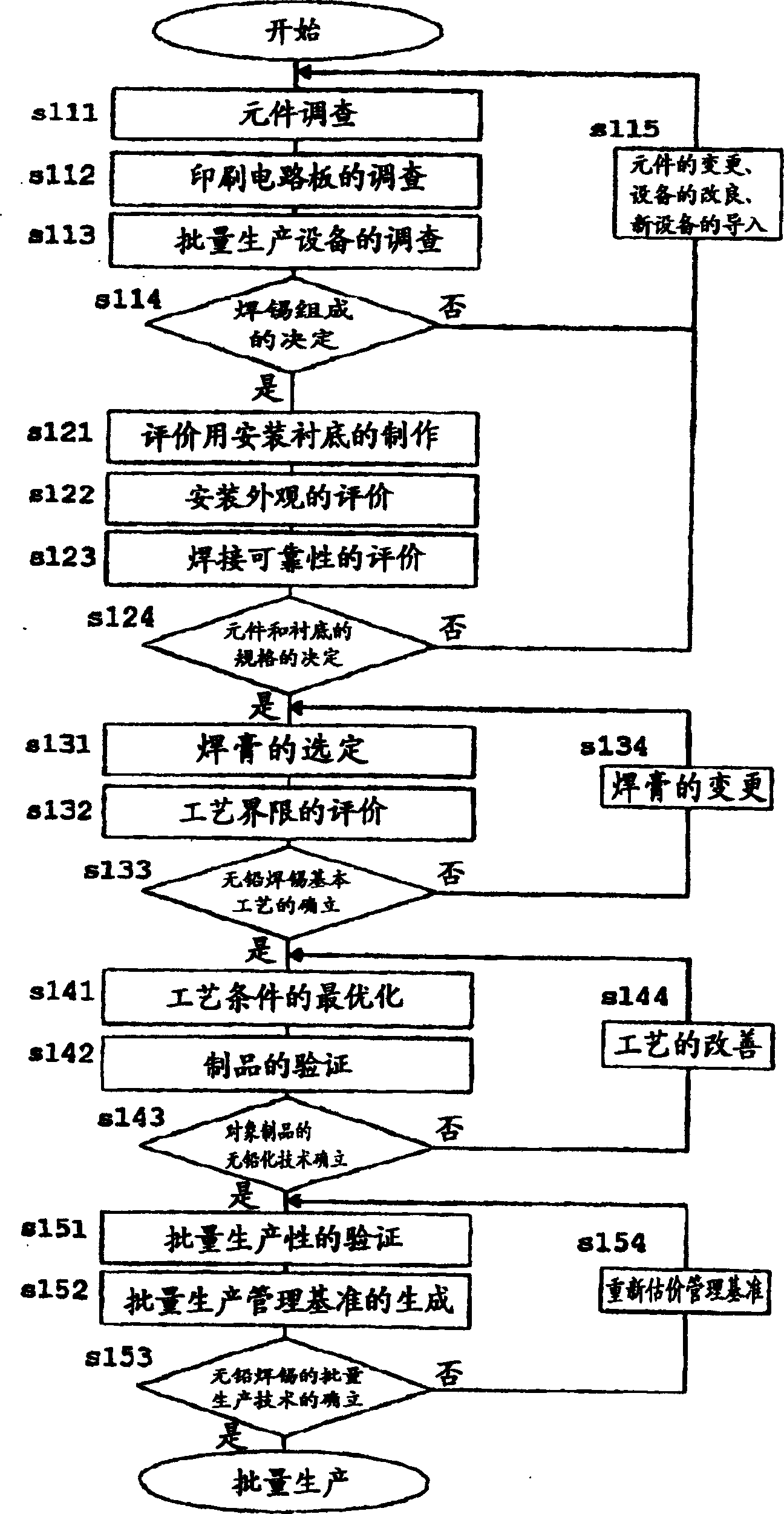

[0075] [Example 1: Reflow installation]

[0076] Below, refer to figure 1 is a flowchart illustrating a method of manufacturing a wiring substrate related to reflow mounting according to the present invention. In the following description, a method of manufacturing a wiring substrate using a soldering process based on reflow mounting will be described, but the steps in this flow chart will again study the process that has entered the mass production stage, making it easier to find out the cause of soldering failures. Although it can be used to improve manufacturing yield, this flow chart can also be applied when designing a manufacturing process of a manufacturing method of a mounted wiring substrate using reflow mounting.

[0077] (s111: Component investigation and confirmation steps)

[0078] The first step (s111) is a step of investigating and confirming components to be mounted or used on the mounting wiring board. In this step, the heat-resistant conditions of the comp...

Embodiment 2

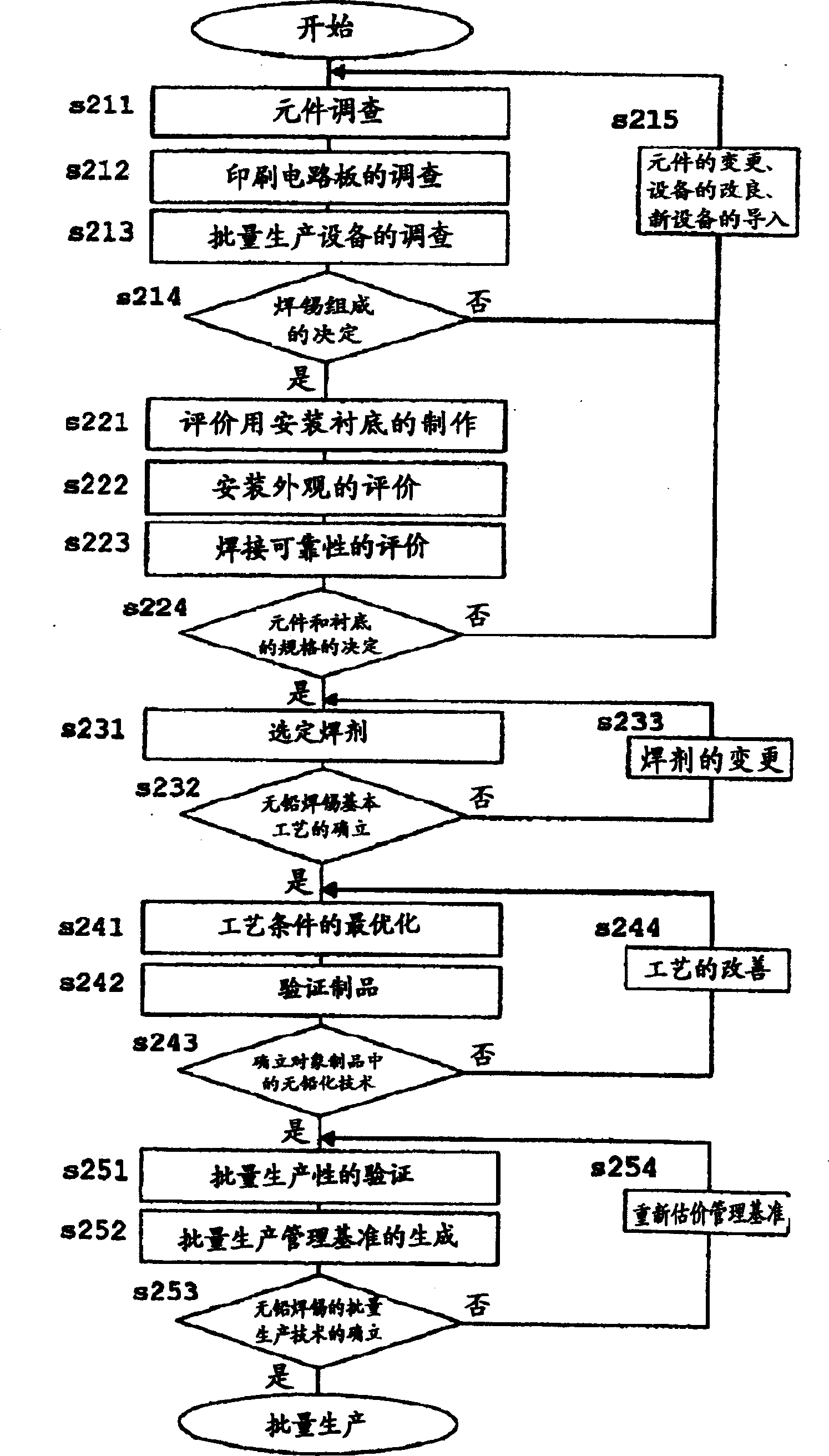

[0125] [Example 2: Process installation]

[0126] refer to figure 2The flowchart of the invention illustrates the manufacturing method of the wiring substrate related to flow mounting. In the following description, a method of manufacturing a wiring substrate using a soldering process based on flow mounting will be described, but the steps of this flow chart reconsider the process that has entered the mass production stage, so that it becomes easier to find out the cause of soldering failures. Although it can be used to improve the manufacturing yield, this flow chart can also be applied to the design of the manufacturing process of the manufacturing method of the mounted wiring substrate using flow mounting, as in the first embodiment.

[0127] (s211: Component investigation and confirmation steps)

[0128] The first step (s211) is a step of investigating and confirming components to be mounted or used on the mounting wiring board. In this step, the heat-resistant conditi...

Embodiment 3

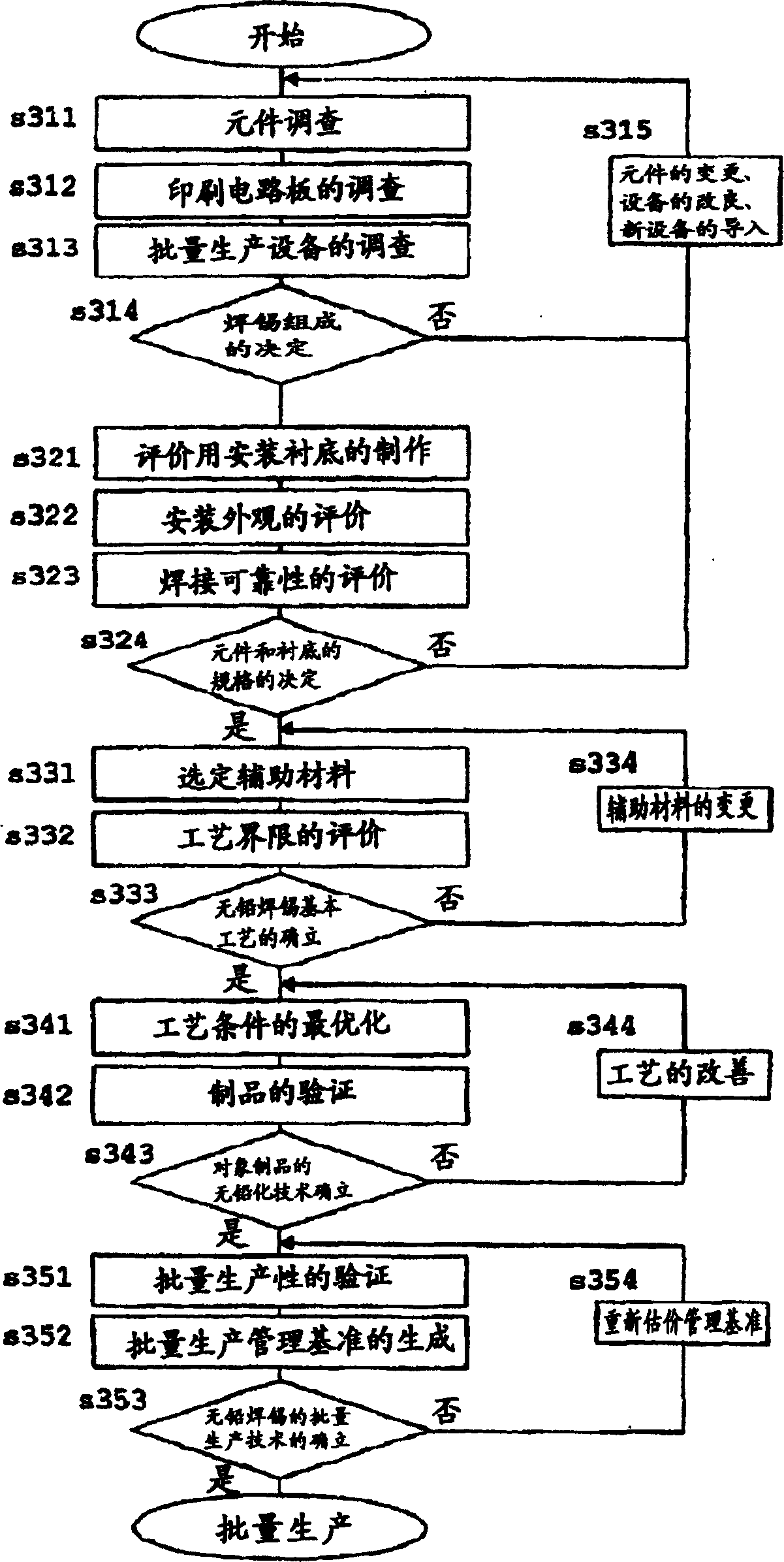

[0172] [Example 3: Hybrid installation]

[0173] refer to image 3 The flowchart of the invention illustrates the manufacturing method of the wiring substrate related to the hybrid mounting. In the following description, a method of manufacturing a wiring substrate using a soldering process based on mixed mounting will be described, but the steps of this flow chart will again study the process that has entered the mass production stage, so as to make it easier to find out the cause of soldering failures. Although it can be used to improve manufacturing yield, this flow chart can also be applied when designing a manufacturing process using a method of manufacturing a mounted wiring substrate for hybrid mounting.

[0174] (s311: Component investigation and confirmation steps)

[0175] The first step (s311) is a step of investigating and confirming components to be mounted or used on the mounting wiring board. In this step, investigate and confirm the heat-resistant conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com