Heating cup body manufacturing method

A production method and technology for heating cups, which are applied in the directions of manufacturing tools, metal processing equipment, applications, etc., can solve problems such as the falling off of heating devices, and achieve the effects of preventing poor welding, good use safety, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

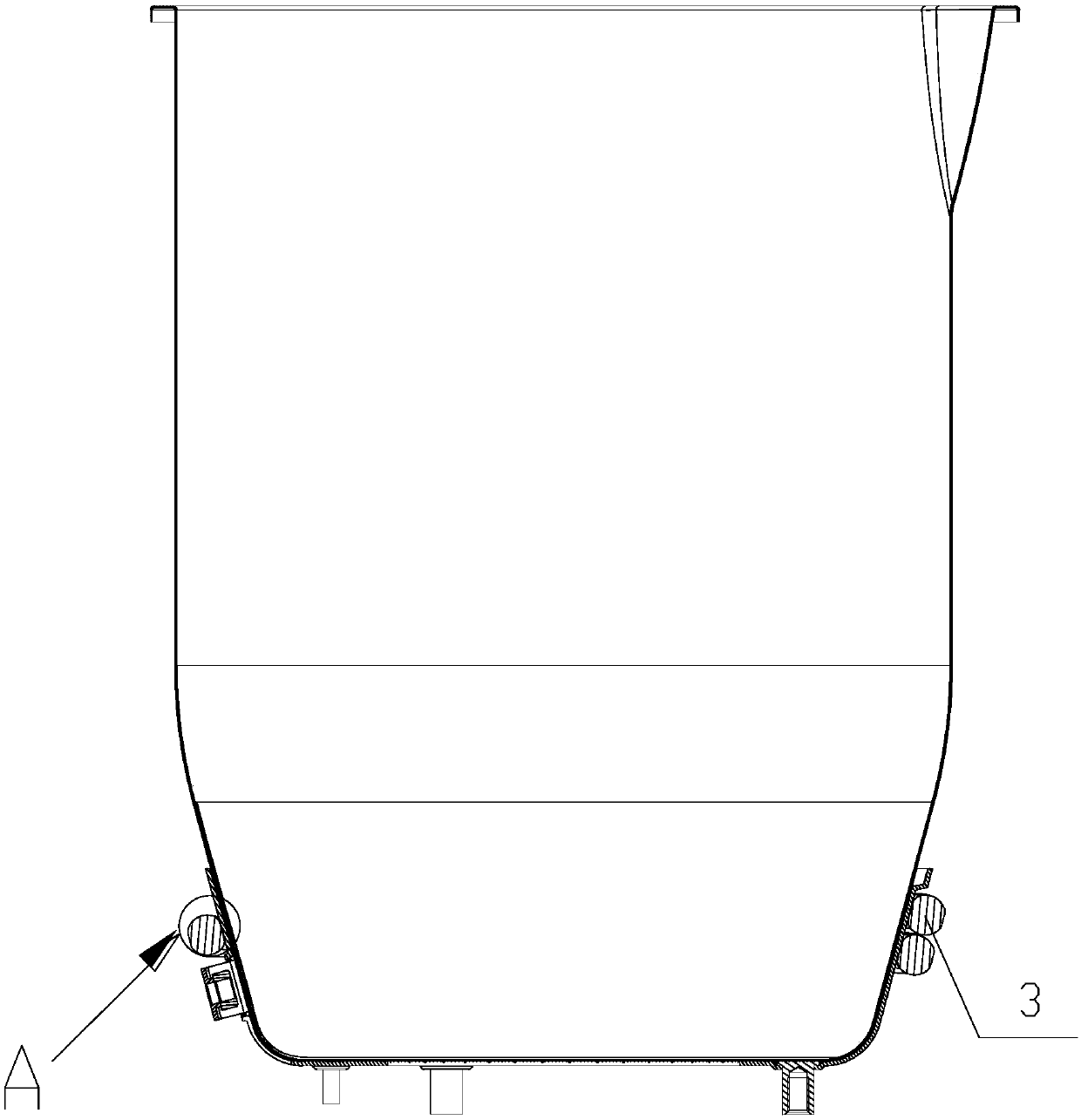

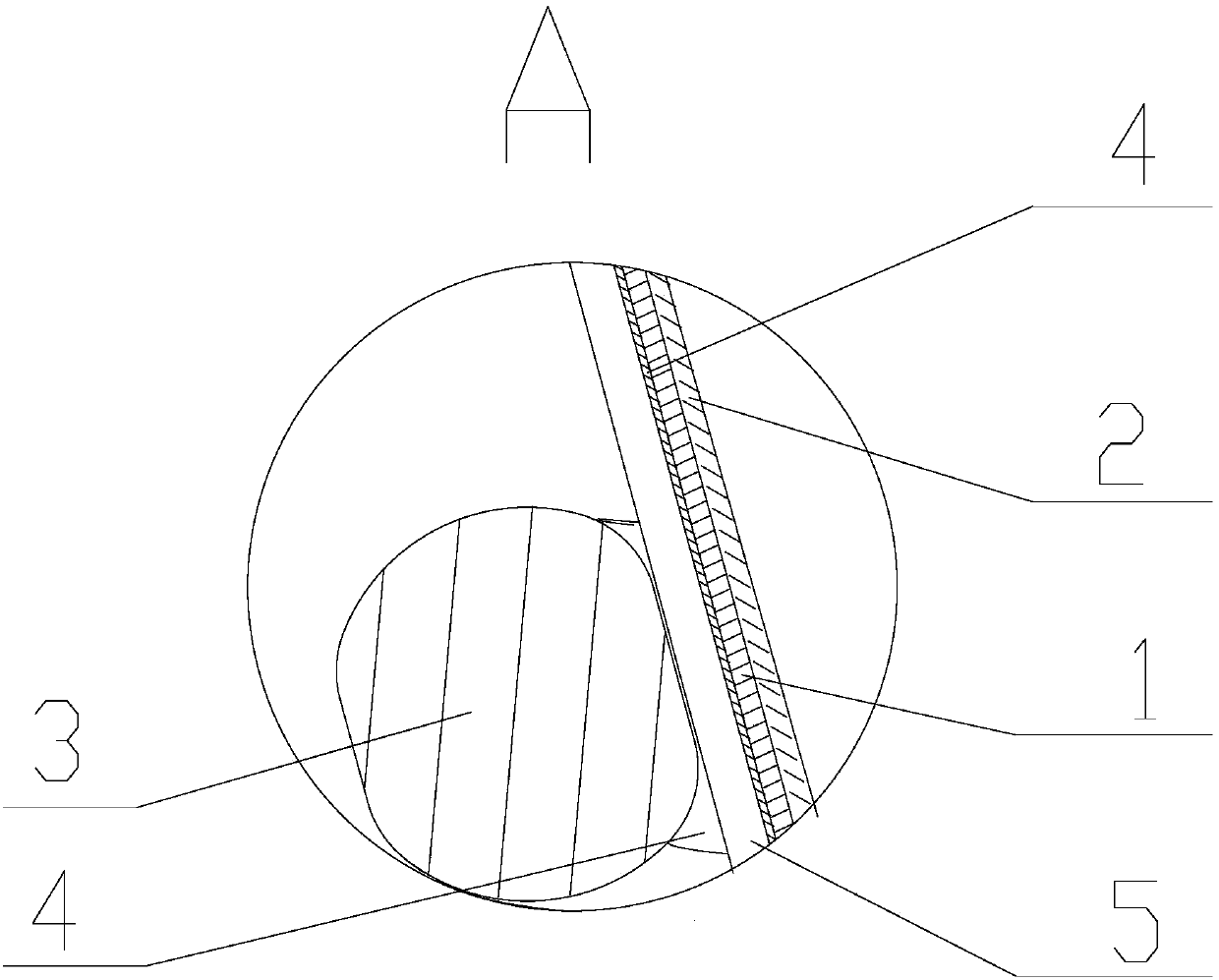

[0046] The safe heating cup body provided by the present invention, such as figure 1 and figure 2 As shown, it includes: a metal inner cup 1, which is sintered with a non-stick layer 2 on its inner surface; and a heating device, which is welded on the outer surface of the metal inner cup 1 by a welding medium 4; wherein, the heating device and the The melting point of the metal inner cup 1 is higher than the melting point of the welding medium 4 , and the melting point of the welding medium 4 is higher than the sintering temperature of the non-stick layer 2 .

[0047] In the safe heating cup body provided by the present invention, the heating device is welded on the outer surface of the metal inner cup 1 through the welding medium 4, and then the non-stick layer 2 is sintered on the inner surface of the metal inner cup 1, because the heating device and the metal The melting point of the inner cup 1 is higher than the melting point of the welding medium 4, and the melting poi...

Embodiment 2

[0065] The manufacturing method of the heating cup provided in this embodiment, such as Figure 4 shown, including:

[0066] Welding stage: welding the heating device on the outer surface of the metal inner cup through the welding medium;

[0067] Sintering stage: after the welding stage, a non-stick layer is sintered on the inner surface of the metal inner cup, the sintering temperature of the non-stick layer is T2;

[0068] Wherein, the melting point of the heating device and the metal inner cup is higher than the melting point T1 of the welding medium, and the melting point T1 of the welding medium is higher than the sintering temperature T2 of the non-stick layer.

[0069] In the manufacturing method of the heating cup body provided by the present invention, the heating device is welded on the outer surface of the metal inner cup by welding medium, and then the non-stick layer is sintered on the inner surface of the metal inner cup, due to the melting point of the heating...

Embodiment 3

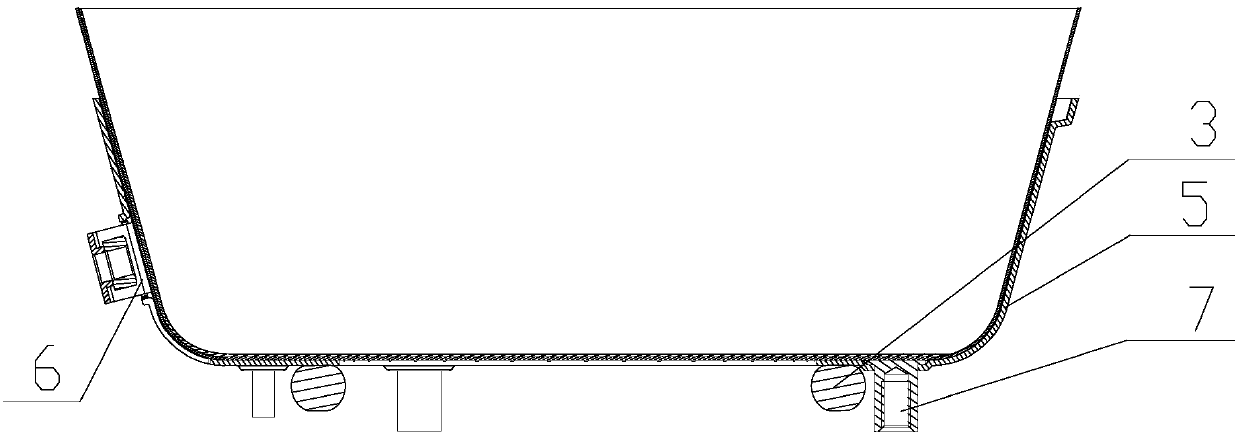

[0071] The manufacturing method of the heating cup provided in this embodiment, such as Figure 5 shown, including:

[0072] Welding stage: welding the heating device on the outer surface of the metal inner cup through the welding medium;

[0073] Cleaning stage: performing desoldering treatment on the surface of the metal inner cup after welding;

[0074] Sintering stage: sintering a non-stick layer on the inner surface of the metal inner cup after desoldering treatment, the sintering temperature of the non-stick layer is T2;

[0075] Sealing stage: after the temperature drops after sintering, seal the port of the heating device;

[0076] Wherein, the melting point of the heating device and the metal inner cup is higher than the melting point T1 of the welding medium, and the melting point T1 of the welding medium is higher than the sintering temperature T2 of the non-stick layer.

[0077] In the manufacturing method of the heating cup body provided by the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com