Surface mount structure and circuit board with same

A surface mount and circuit board technology, applied in the direction of printed circuits connected with non-printed electrical components, printed circuit components, electrical connection printed components, etc., can solve problems affecting the quality of electronic component placement, and improve signal quality The effect of transmitting quality, avoiding poor welding, and improving placement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The surface mount structure of the technical solution and the circuit board with the surface mount structure will be described in further detail below with reference to the drawings and embodiments.

[0019] The embodiment of the technical solution provides a surface mount structure, which is used for fixedly mounting electronic components with pins and solder chassis on a circuit board.

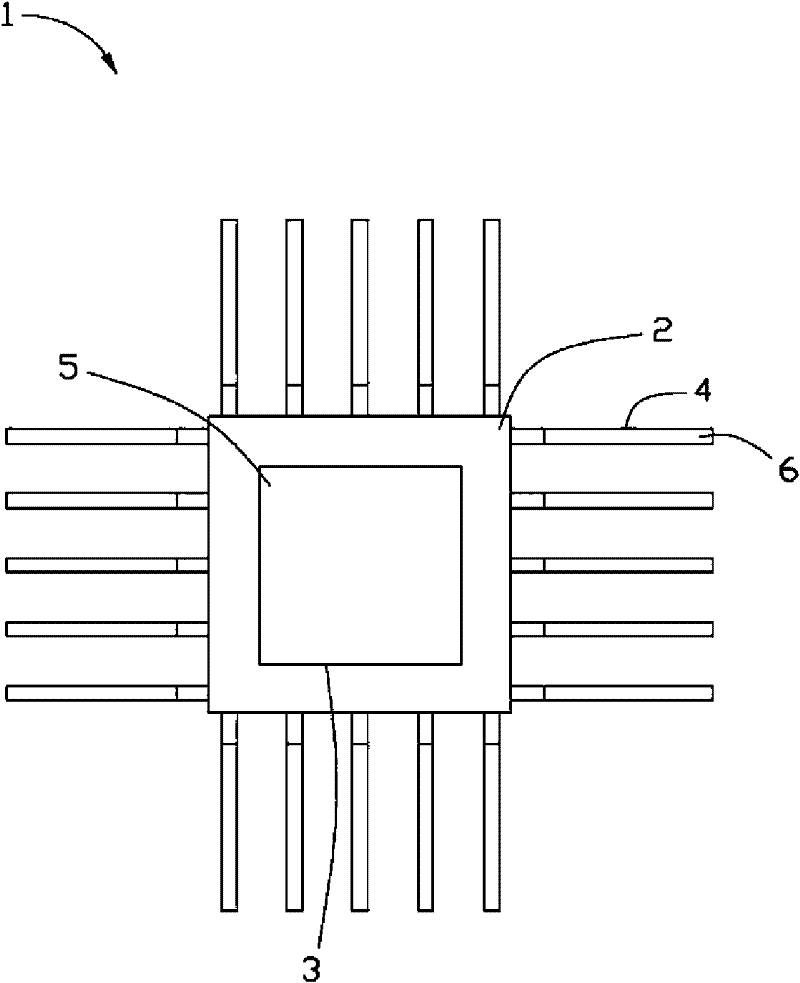

[0020] See figure 1 The above-mentioned electronic component 1 for mounting has a chip main body 2, a soldering chassis 3, and pins 4. Among them, the welding chassis 3 is formed on the bottom surface of the chip main body 2, and the pins 4 are formed on the peripheral edges of the chip main body 2. The welding chassis 3 has a first bottom surface 5 for welding. The pin 4 has a second bottom surface 6 for soldering.

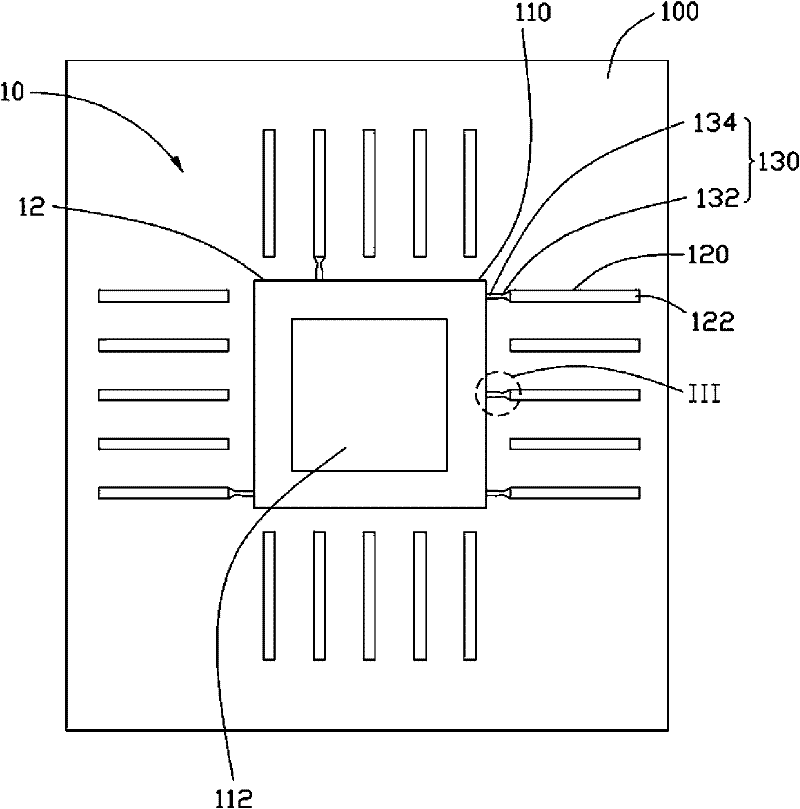

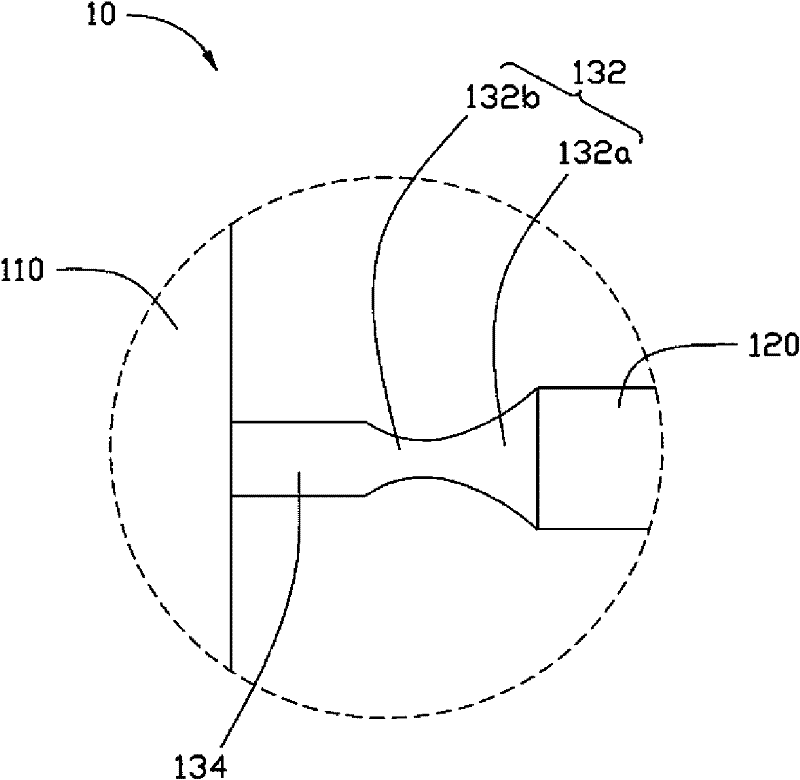

[0021] See figure 2 versus image 3 In the first embodiment, the surface mount structure 10 includes pads 12 formed on the circuit board 100. Wherein, the pad 12 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com