Lithium-sulfur battery separator material, preparation method thereof and application thereof

A technology of lithium-sulfur batteries and diaphragm materials, which is applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of blocked lithium ion transmission channels, poor cycle performance of lithium-sulfur batteries, and low coulombic efficiency, and achieve improved Coulombic efficiency and cycle stability, good electrochemical advantages, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

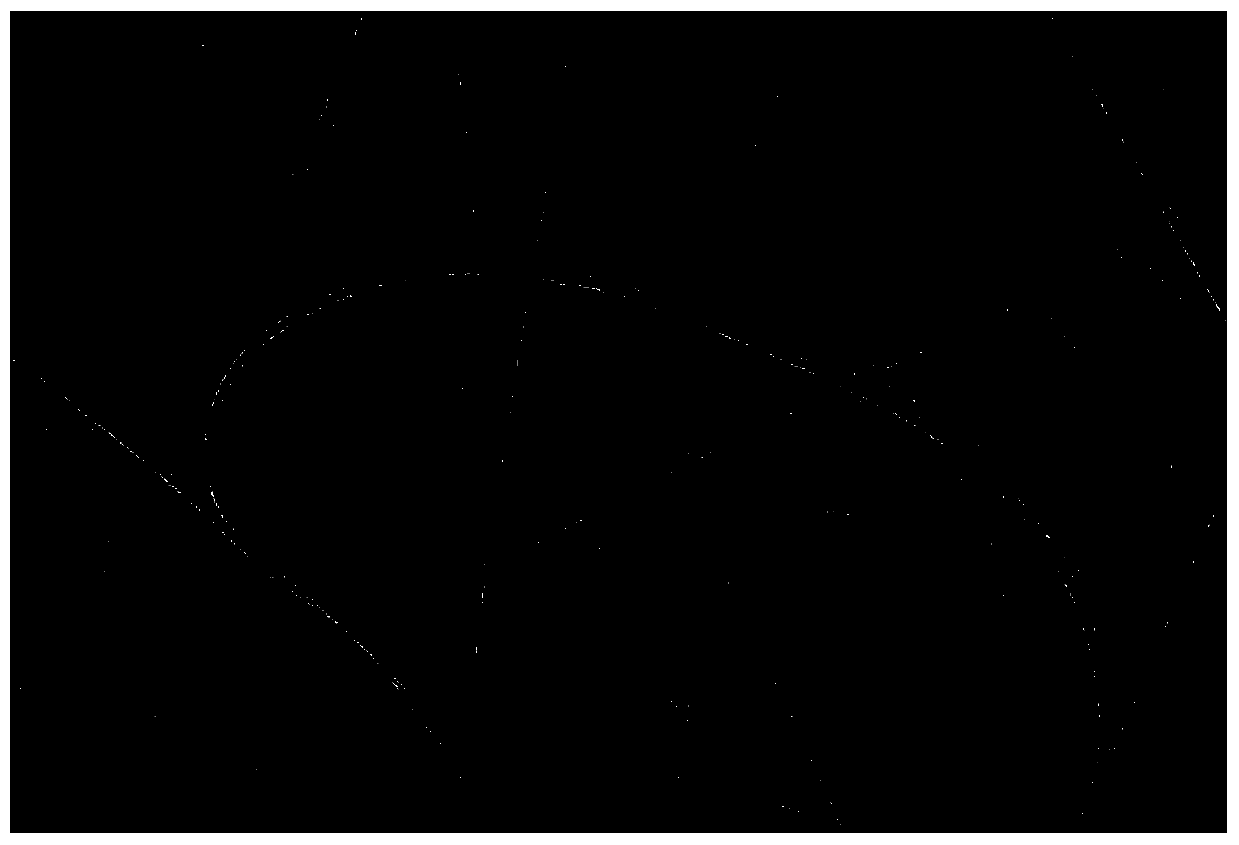

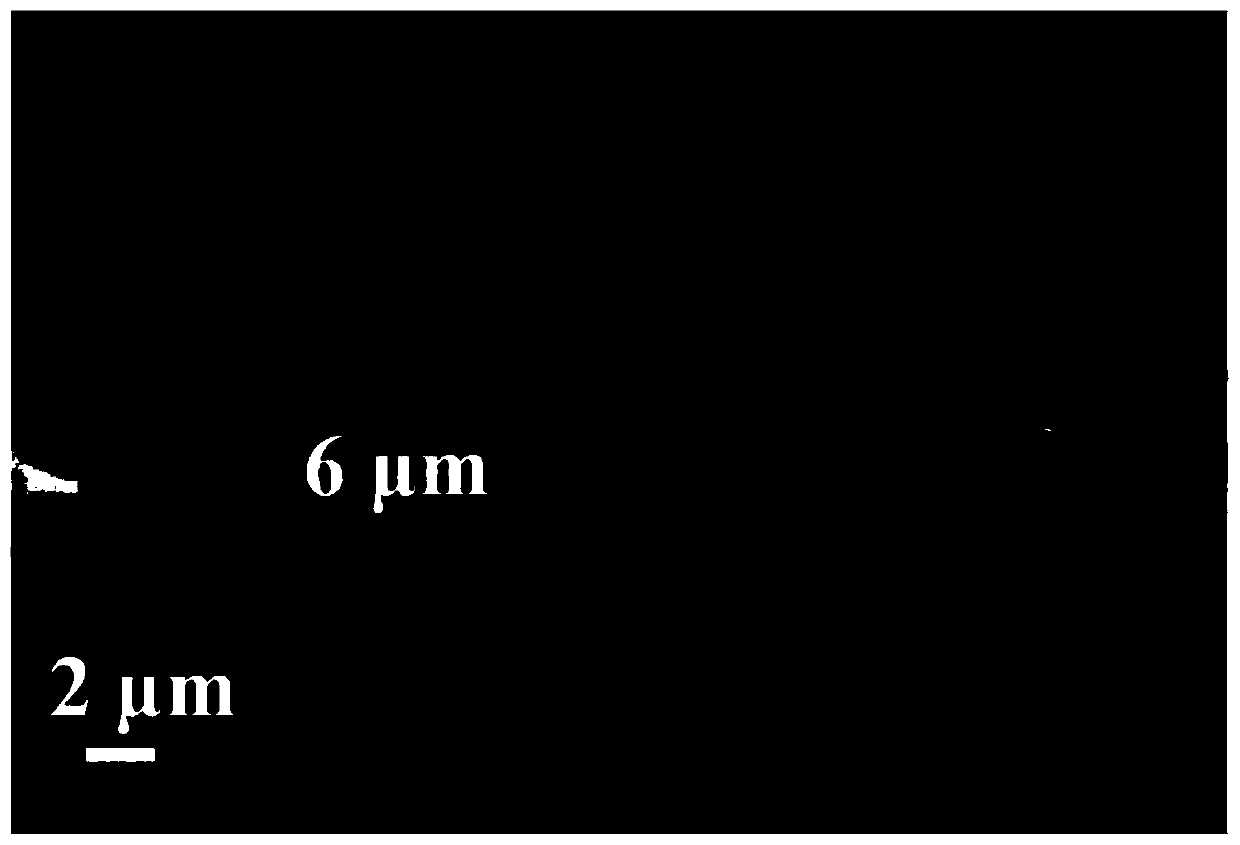

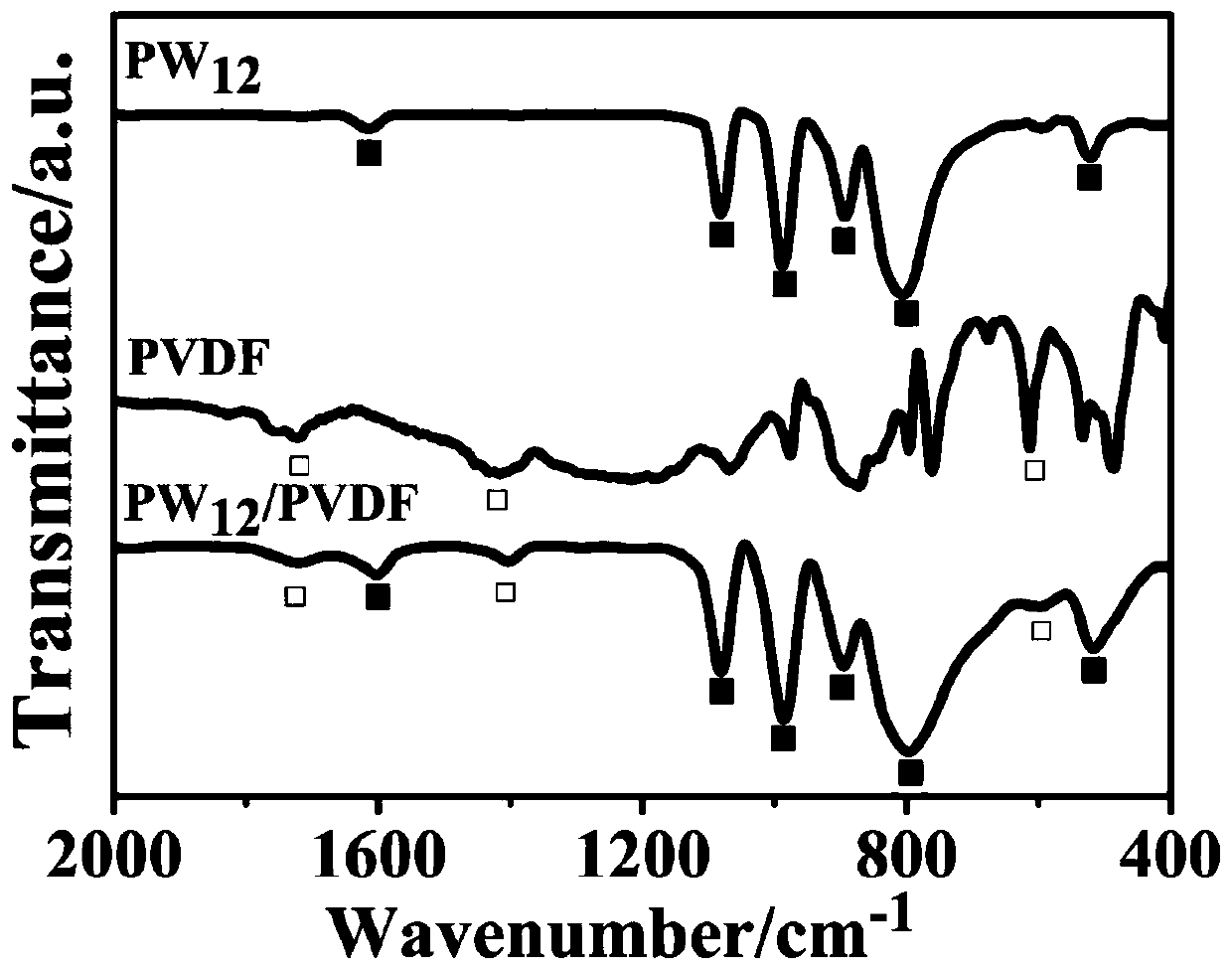

[0019] The preparation method of composite material of the present invention, comprises the steps:

[0020] Dissolve a certain amount of PW12 powder in a certain amount of DMF solution, and magnetically stir for several minutes until the PW12 12 The powder is completely dissolved to form a uniform and transparent mixed solution, and then a certain amount of PVDF powder is dissolved in the mixed solution, heated in an oil bath, stirred, and left to stand to prepare a uniform spinning solution, which is placed on the PP film through an electrospinning machine , dried in vacuum to obtain a new type of PW 12 / PVDF spun diaphragm composite.

Embodiment 1

[0022] 1) Preparation of PW 12 / Spinning solution for PVDF spinning diaphragm material:

[0023] Take 0.75gPW 12 Dissolve in 5mL DMF solution, heat the oil bath at 50°C, stir magnetically for 5 h, then add 0.5g PVDF powder, stir magnetically for 3 h at 50°C to form a uniform and transparent spinning solution, and let it stand for several minutes to prepare for static electricity Spinning use.

[0024] Select a certain amount of PW in this step 12 , DMF and PVDF, under these conditions can form a uniform spinning solution with a certain viscosity; control the heating temperature is for PW 12 , DMF and PVDF are better dissolved together to speed up the reaction, too high or too low temperature will have a great impact on the prepared spinning solution.

[0025] 2) Preparation of PW 12 / PVDF spinning diaphragm material:

[0026] The PW obtained in step 1) 12 / PVDF spinning diaphragm material spinning solution, by using an electrospinning machine, the distance between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com