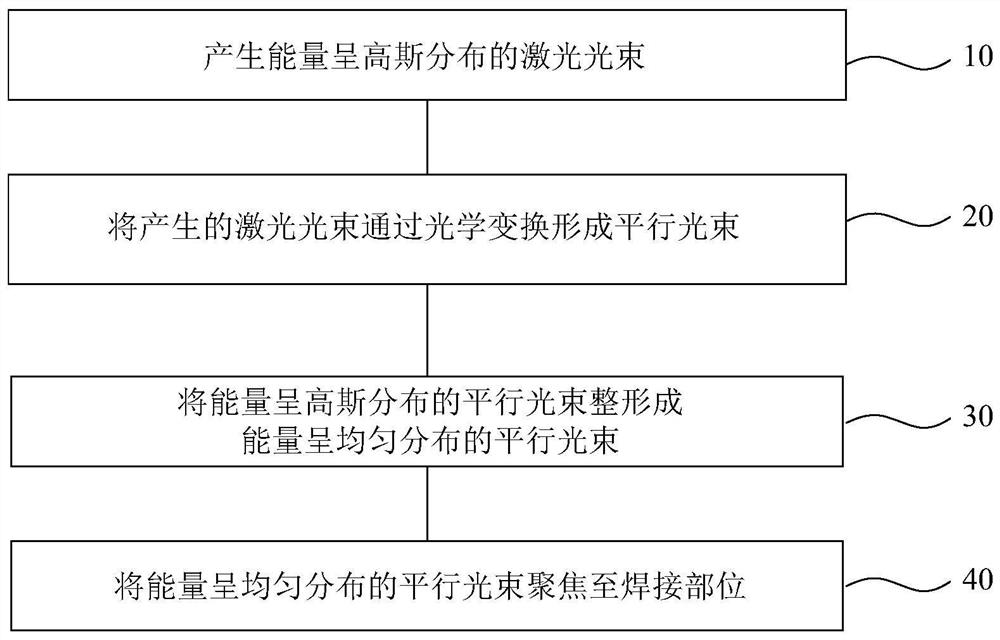

Laser welding method and device for laser welding

A laser welding and laser beam technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of beam energy loss, inability to change the focal length, increase the temperature of the shaping diffractive optical element, etc., to achieve small energy loss, Avoid bad soldering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

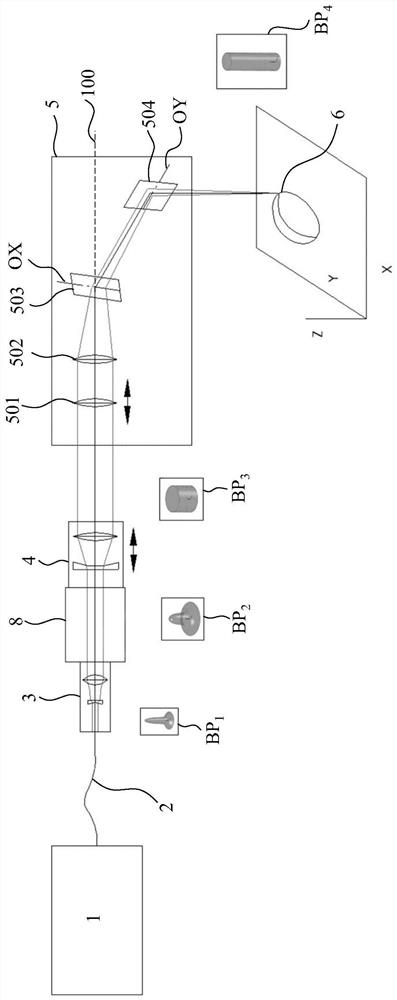

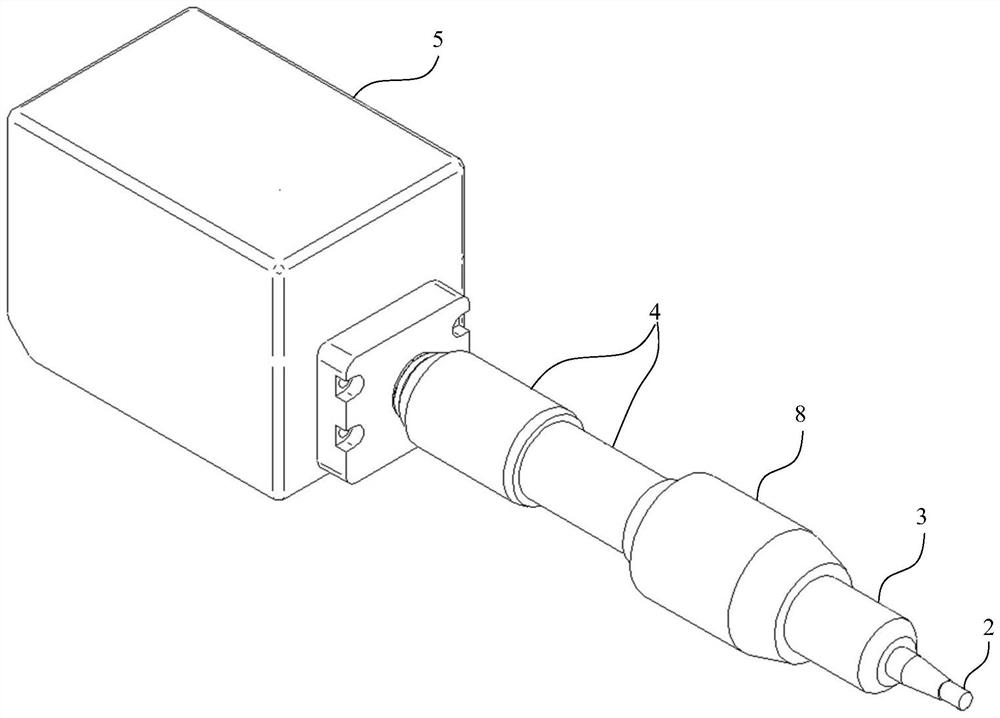

[0049]Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. The following description is merely exemplary in nature and is not intended to limit the invention and its application or uses. In the various views, corresponding components or parts are provided with the same reference signs.

[0050] In the present invention, in order to better describe the characteristics of the laser beam, different spot shapes are used to represent some features of the laser beam, wherein the spot shape is a three-dimensional configuration, and the bottom surface shape of the three-dimensional configuration represents the cross-sectional shape of the laser beam, The height of each point in the shape of the bottom surface of the three-dimensional configuration represents the beam intensity or energy value of each point in the cross-sectional shape of the laser beam.

[0051] In this article, the term "optical path" refers to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com