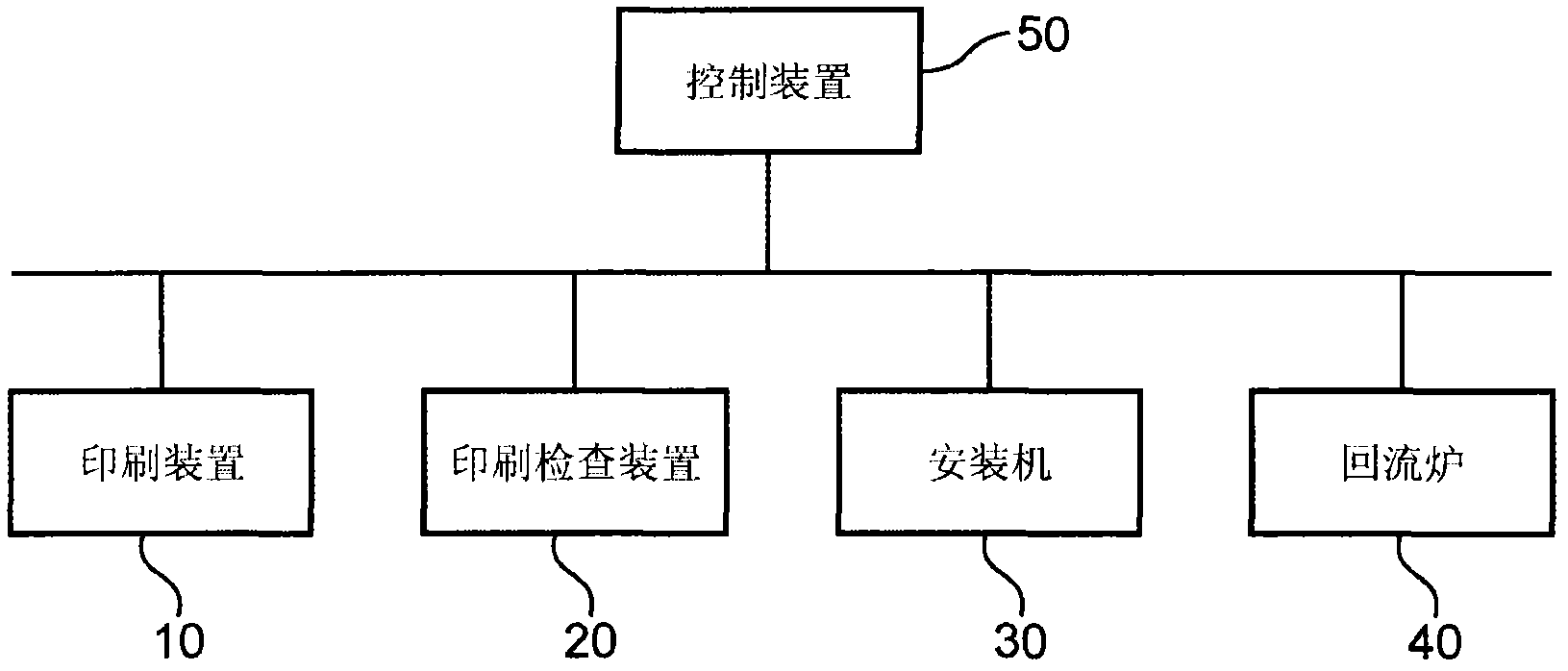

Element mounting device and element mounting method

A technology of installation device and installation position, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, and can solve problems such as poor welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

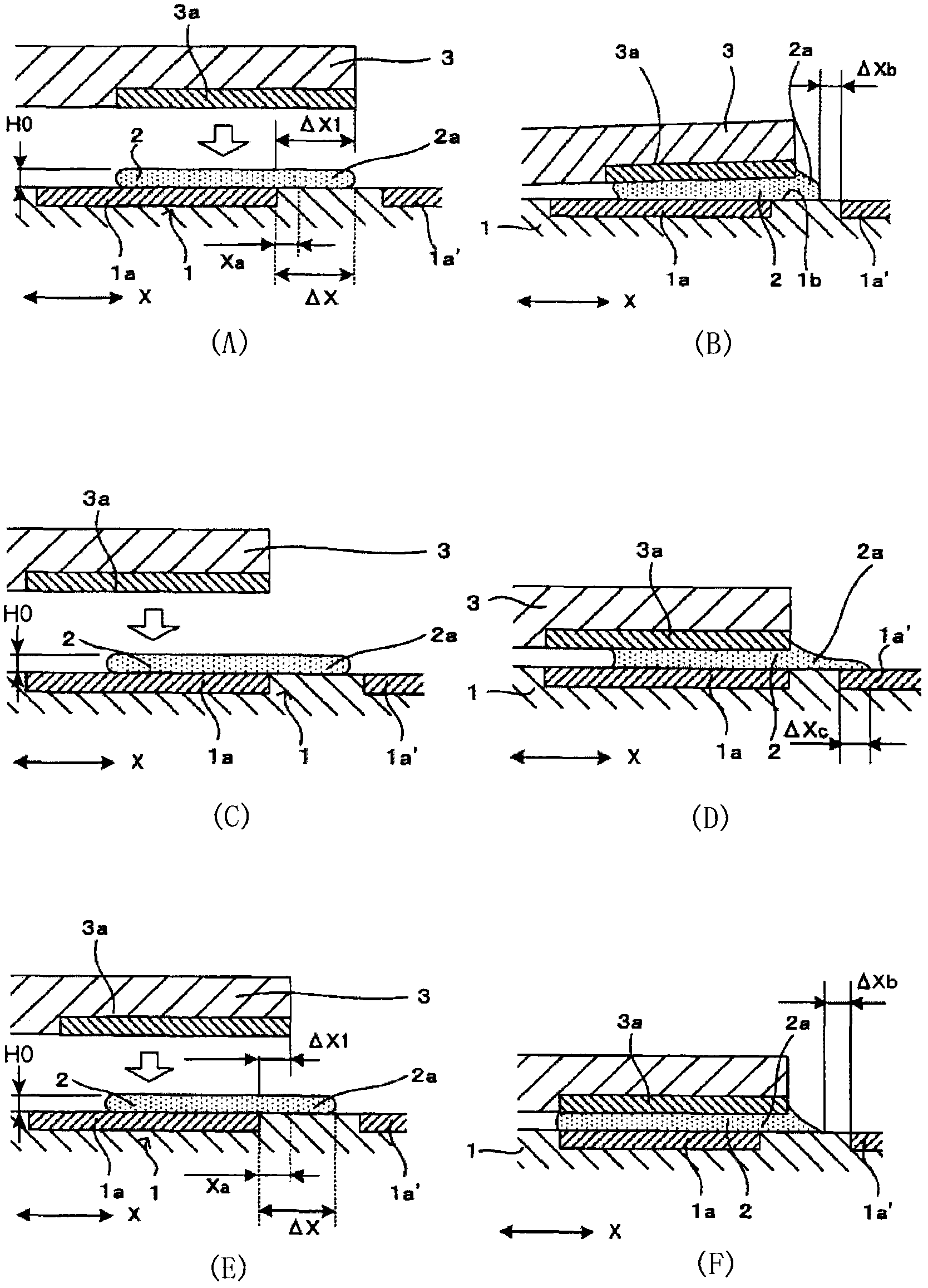

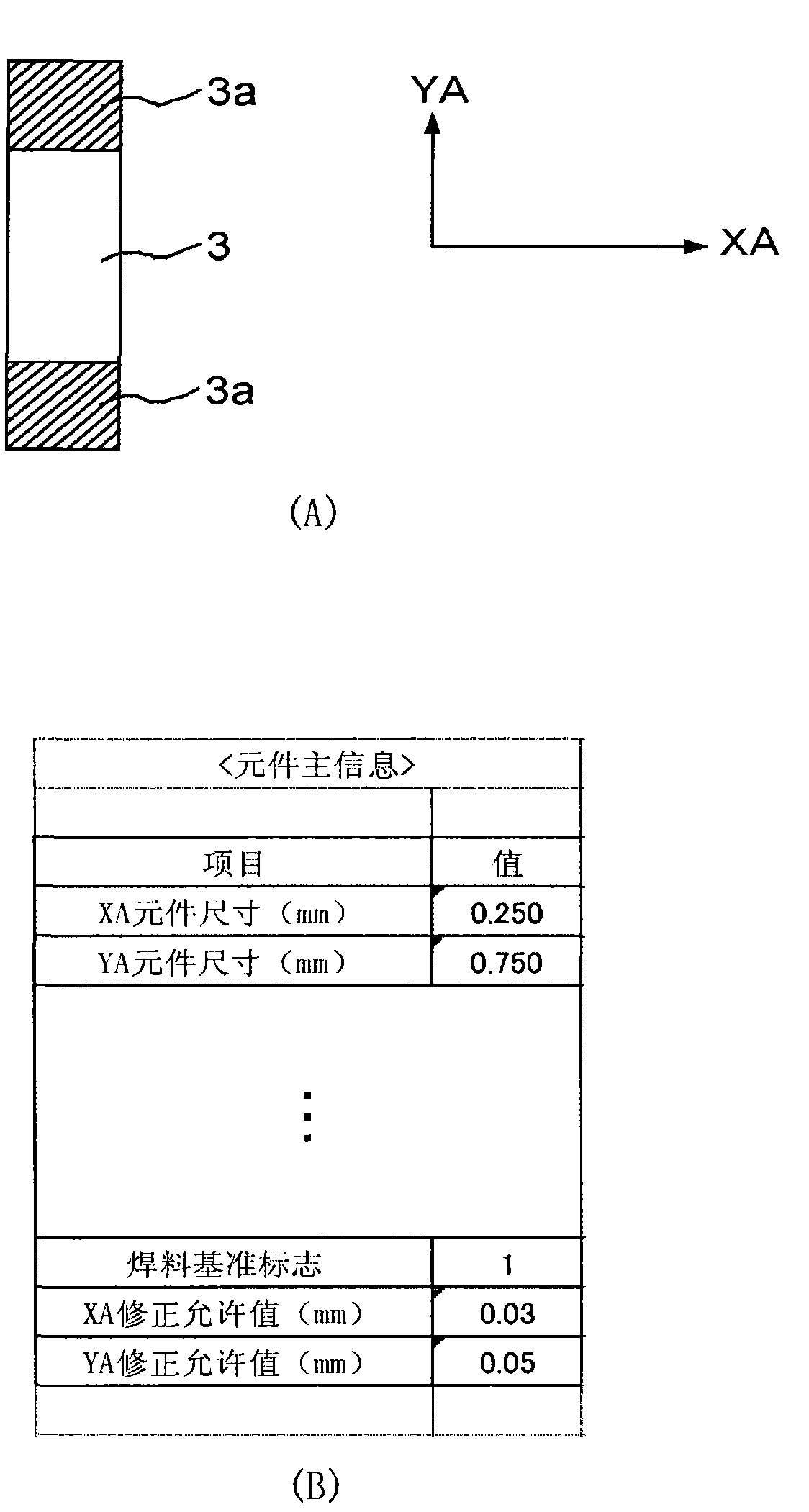

[0040] Figure 5 It is a plan view which shows the mounting machine which is one embodiment of the component mounting apparatus concerning this invention. Figure 6 yes means Figure 5 Block diagram of the main electrical structure of the setup machine shown. In this mounter 30 , a board transfer mechanism 302 is provided on a base 311 to transfer the printed board 1 on which cream solder has been printed by the printing device 10 in a predetermined transfer direction (+X axis direction). More specifically, the substrate transfer mechanism 302 has the function of transferring the substrate 1 from the base 311 to Figure 5 A pair of conveyor belts 321, 321 are conveyed to the left side from the right side. After the conveyor belts 321, 321 carry in the substrate 1, they are stopped at a designated mounting operation position (the position of the substrate 1 shown in this figure), and the substrate 1 is fixed and held by a holding device not shown in the figure. Next, the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com