Automatic five-wire submerged arc welding method for thick-wall welded pipes

A technology of automatic submerged arc welding and welding method, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of poor welding joint stability, large heat input, etc., to achieve high productivity, small heat affected zone, welding seam The effect of uniform metal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

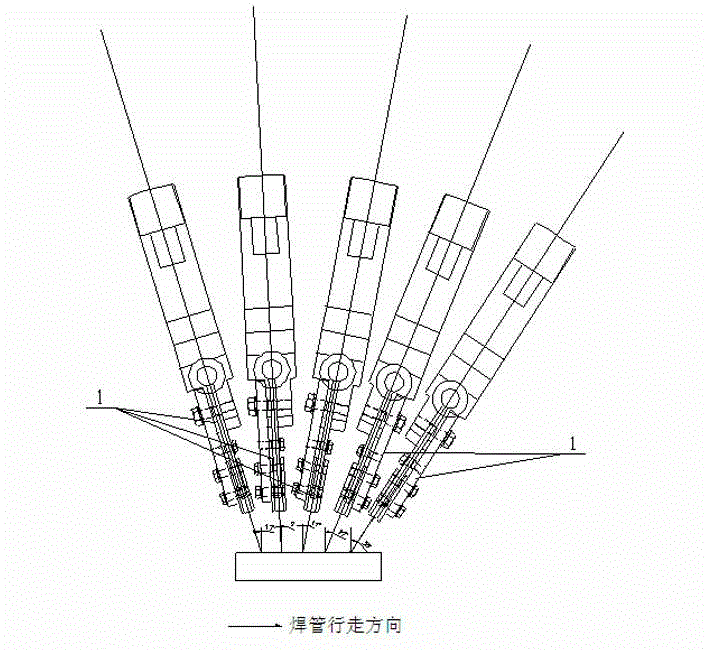

[0020] like figure 1 As shown, a five-wire automatic submerged arc welding method for thick-walled welded pipes according to the present invention includes five welding wires 1, which obtain stable weld joint performance, and the specific implementation methods are:

[0021] 1. Power configuration and connection method:

[0022] The internal and external five-wire welding adopts the tandem five-wire four-power welding technology. The power supply uses Lincoln's DC and AC power supplies, and adopts a DC-AC hybrid power supply configuration: DC-AC-AC-AC-AC. When the AC power supply is connected, the phase difference of the current is 120o, which can effectively avoid the electromagnetic interference generated between the AC arcs and ensure the stable combustion of the arc during welding.

[0023] 2. Spatial position of welding wire 1:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com