Automatic flat fillet welding method of heavy arc plate

An automatic welding and circular arc plate technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to meet the quality requirements of weld seams, beautiful shape, and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

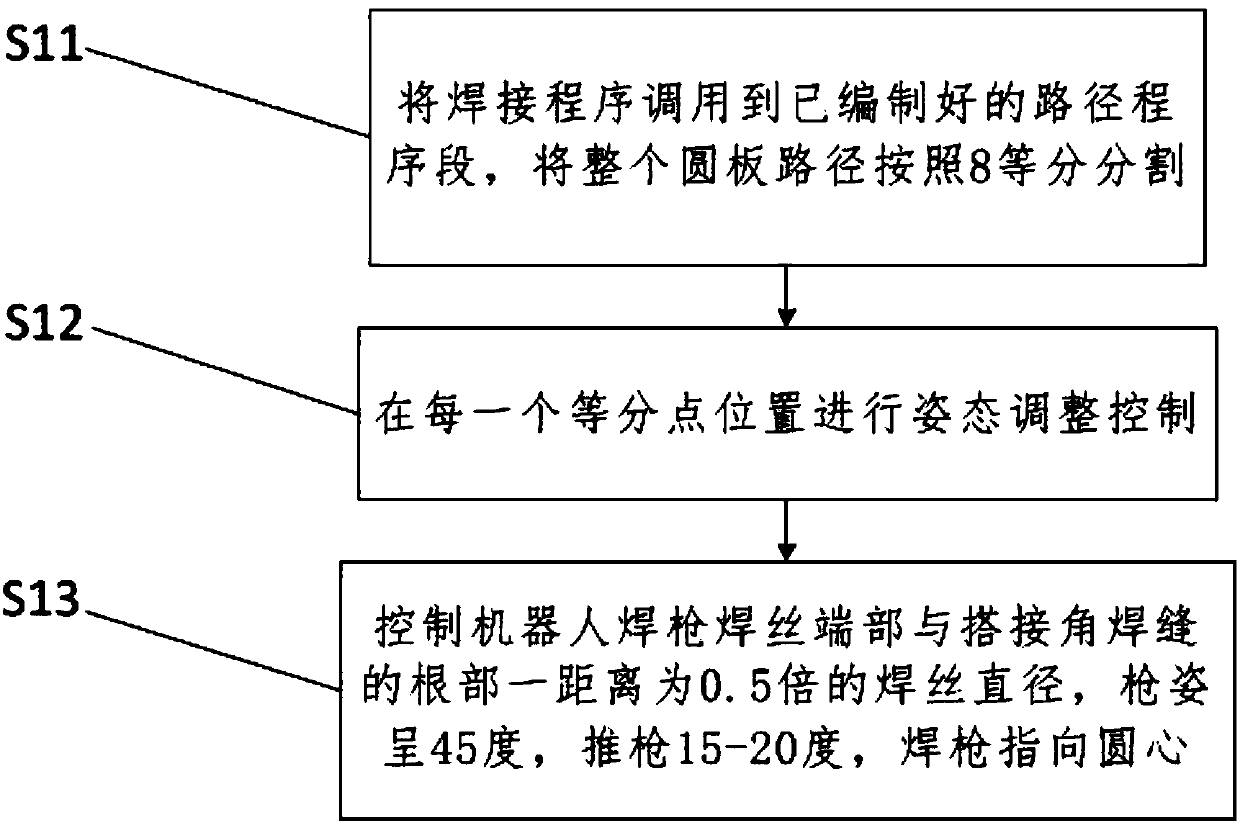

[0033] 1. According to the robot welding program command, design a parametric programming program module, and recalibrate the position and shape parameters of the programming module according to the actual workpiece. The position of the point is adjusted and controlled, and the distance between the end of the welding wire of the robot welding gun and the root of the lap fillet weld is 0.5 times the diameter of the welding wire. The gun posture is 45 degrees, and the gun is pushed at 15-20 degrees.

[0034] 2. Process parameter setting:

[0035] According to the thickness requirements of the workpiece, different process parameters are set respectively. The process parameters of the typical single-pass welding leg size of 6mm for medium-thick plate welding are used. The welding speed is 35-40cm / min, the welding current is 190-210A, the welding voltage is 23V, and the pendulum Frequency 3Hz, swing amplitude 1.8mm, stay 0.1s on both sides.

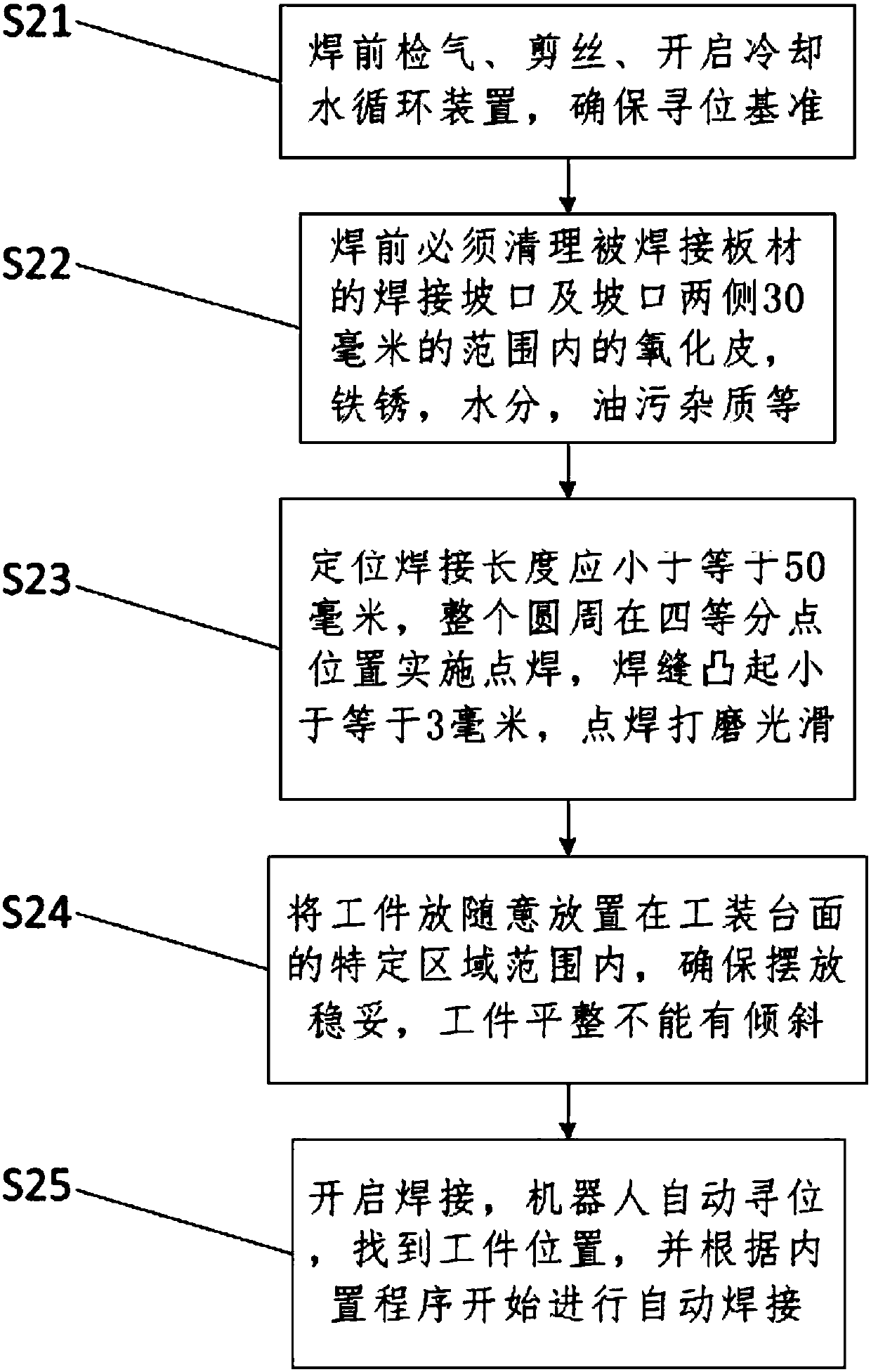

[0036] 3. Workpiece preparation and we...

Embodiment 2

[0044] 1. According to the robot welding program command, design a parametric programming program module, and recalibrate the position and shape parameters of the programming module according to the actual workpiece. The position of the point is adjusted and controlled, and the distance between the end of the welding wire of the robot welding gun and the root of the lap fillet weld is 0.5 times the diameter of the welding wire. The gun posture is 45 degrees, and the gun is pushed at 15-20 degrees.

[0045] 2. Process parameter setting:

[0046] According to the thickness requirements of the workpiece, different process parameters are set respectively. The process parameters of the typical single-pass welding leg size of 8mm for medium-thick plate welding are used. The welding speed is 30-35cm / min, the welding current is 230-250A, the welding voltage is 24V, and the pendulum Frequency 2.5Hz, swing 3mm, stay 0.1s on both sides.

[0047] 3. Workpiece preparation and welding:

...

Embodiment 3

[0055] 1. According to the robot welding program command, design a parametric programming program module, and recalibrate the position and shape parameters of the programming module according to the actual workpiece. The position of the point is adjusted and controlled, and the distance between the end of the welding wire of the robot welding gun and the root of the lap fillet weld is 0.5 times the diameter of the welding wire. The gun posture is 45 degrees, and the gun is pushed at 15-20 degrees.

[0056] 2. Process parameter setting:

[0057] According to the thickness requirements of the workpiece, different process parameters are set respectively. The process parameters of the typical single-pass welding leg size of 10mm for medium-thick plate welding are used. The welding speed is 30-35cm / min, the welding current is 230-250A, the welding voltage is 25V, and the pendulum Frequency 2.2Hz, swing 3mm, stay 0.1s on both sides.

[0058] 3. Workpiece preparation and welding:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com