Temperature-controlled mechanical property test device for thin film

A testing device and temperature control technology, applied in the direction of measuring device, using stable tension/pressure to test material strength, strength characteristics, etc., can solve the problems of difficult precise control of angle value, uneven pressure and temperature, complicated process, etc. Achieve the effects of uniform temperature loading area, uniform pressure and temperature, and large temperature loading area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

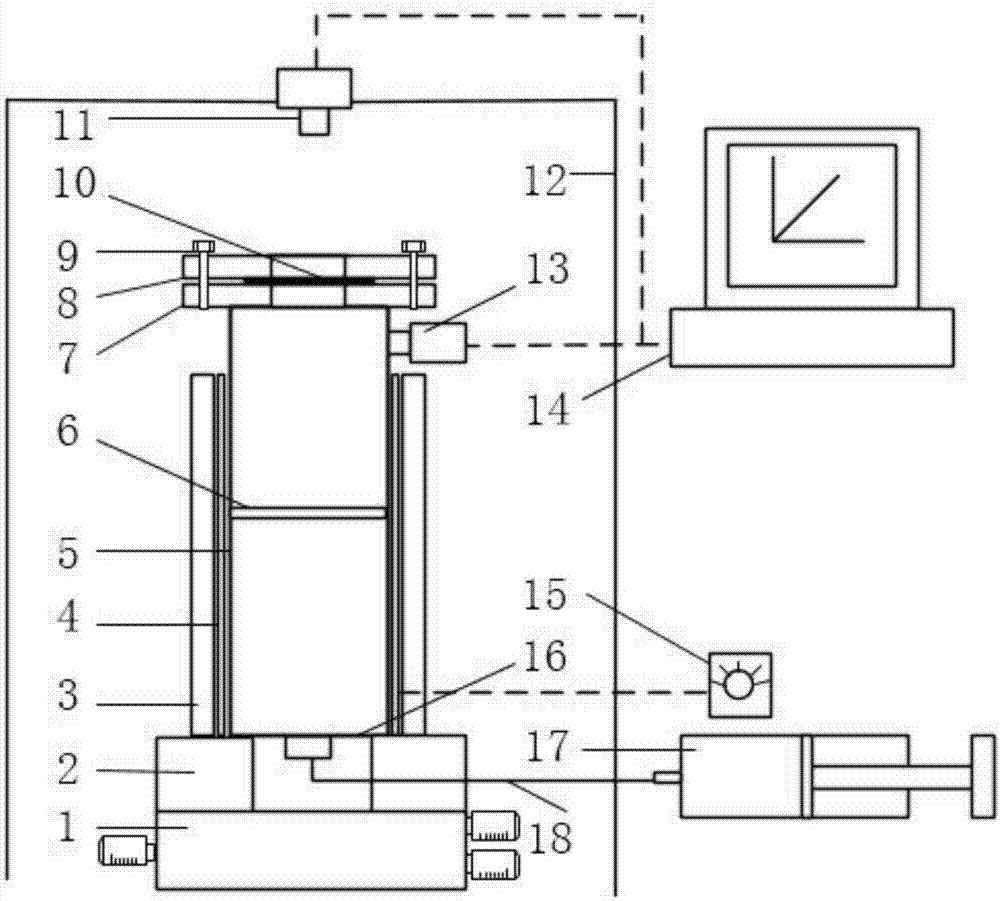

[0031] A temperature-controllable thin film mechanical performance testing device is characterized in that it includes a temperature control part, a deflection measurement part, a pressure loading part, and a specimen clamping structure;

[0032] The temperature control part is arranged outside the pressure loading part; the specimen clamping structure is arranged above the pressure loading part; the deflection measurement part is arranged above the specimen clamping structure.

[0033] The pressure loading part includes a pressure chamber, an equalizer plate 6, a test piece table 7, a pressurized gas pipe 18, a syringe 17, a base 2, and an XYZ axis micro-displacement platform 1;

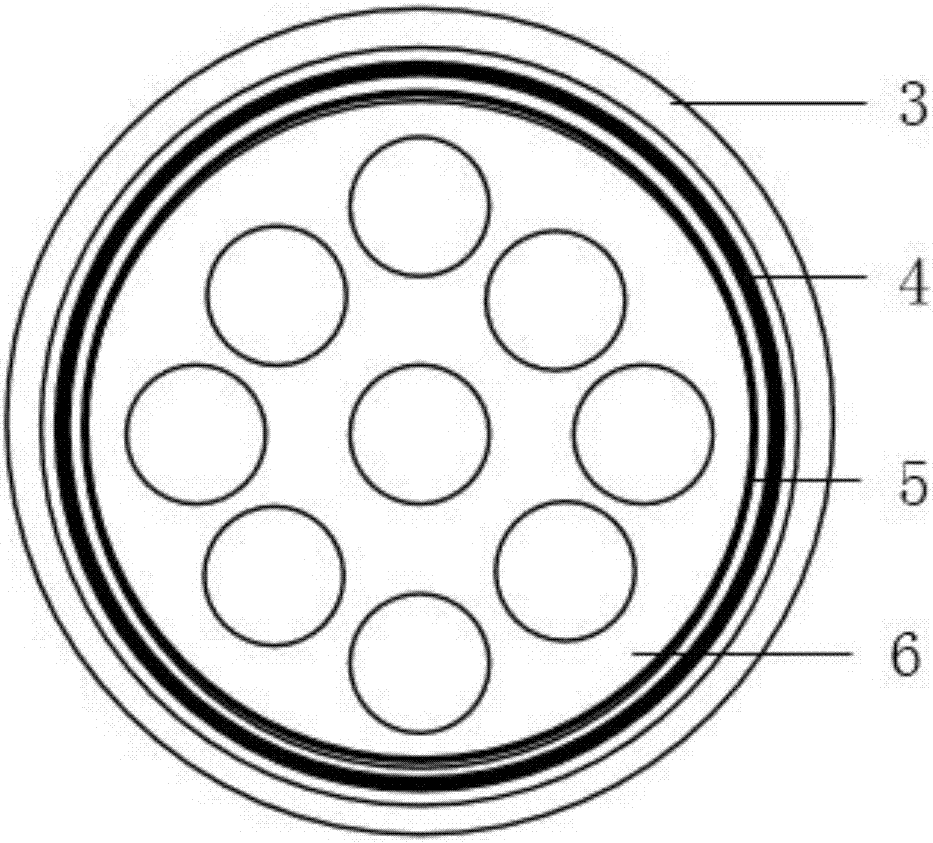

[0034] The pressure chamber adopts large-diameter copper pipe 5, the bottom is provided with end cover 16, and the upper part is provided with test piece table 7;

[0035] The copper tube 5 is provided with a flow equalizer 6, and the end cap 16 is connected with the injector 17 through the pressuri...

Embodiment

[0049] A flow equalizer 6 is installed in the middle of the large-diameter copper tube 5, wherein the flow equalizer 6 is processed with evenly distributed through holes; the test piece platform 7 and the end cover 16 are respectively sealed and installed at both ends of the copper tube 5, wherein the test piece platform 7 is a ring with a smooth surface, and the middle position of the end cover 16 is processed with a connection hole for a pressurized air pipe 18; the outer side of the copper pipe 5 is wrapped with the electric heating belt 4 and the thermal insulation cotton 3 in turn, and the temperature controller 15 is connected with the electric heating belt 4 through a lead wire ; Install the pressure sensor 13 on the wall of the copper pipe 5 close to the position of the test piece table 7; the syringe 17 is sealed and connected with the end cover 16 through the pressurized gas pipe 18; the base 2 is placed on the XYZ axis micro-displacement platform, and the pressure cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com