A kind of steel plate coating glue that can be laminated at low temperature and its preparation method and hot melt adhesive film

A technology of coating glue and steel plate, which is applied in the field of steel plate coating glue, can solve the problems of poor salt spray resistance, corrosion of steel plate, delamination of composite substrate and steel plate, etc., achieve good temperature resistance and improve heat resistance , Solve the effect of easy delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

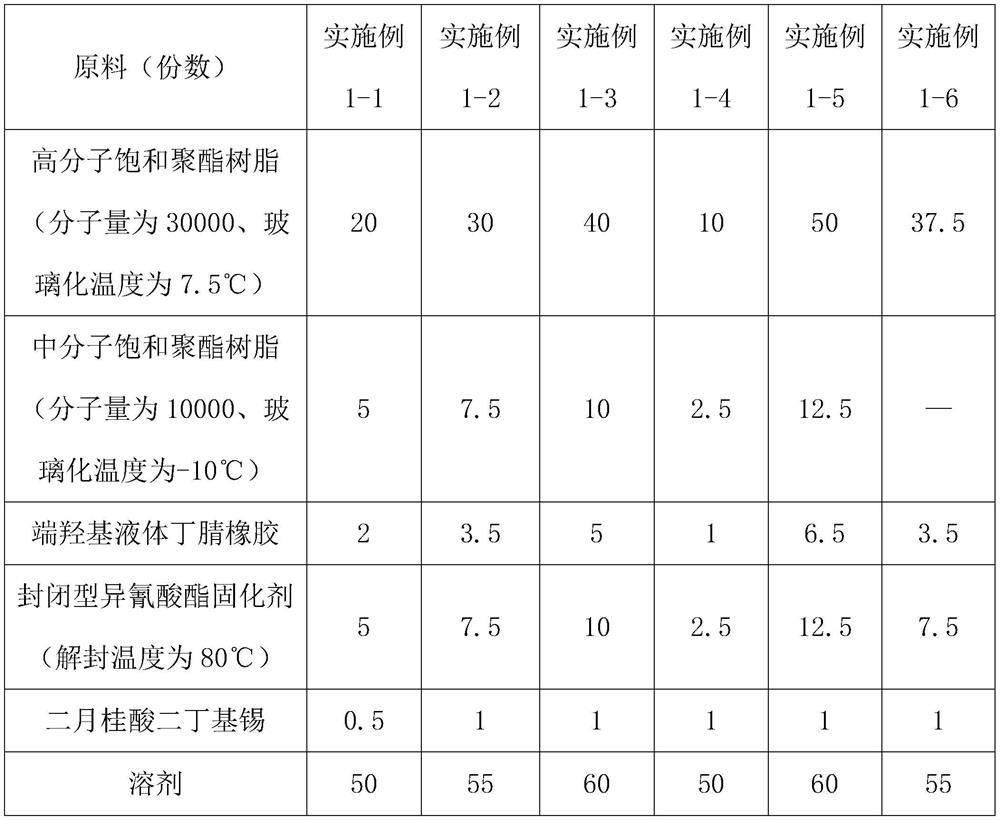

[0027] A steel plate coating adhesive capable of laminating at low temperature, calculated in parts by mass, comprising the following raw material components: 20-40 parts of high-molecular saturated polyester resin, 5-10 parts of medium-molecular saturated polyester resin, hydroxyl-terminated liquid butyl 2-5 parts of nitrile rubber, 5-10 parts of blocked isocyanate curing agent, 0.5-1 part of catalyst and 50-60 parts of solvent.

[0028] The proposal of this technical solution enables the steel plate coating adhesive to be laminated at a temperature lower than 160°C, while ensuring that it has good temperature resistance and salt spray resistance.

[0029] First of all, this technical solution uses saturated polyester resin as the main resin, which can effectively increase the softness of the steel plate coating adhesive colloid and improve the cohesive force of the colloid. At the same time, the saturated polyester resin also has good impact resistance and thermal stability. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com