Modified-graphene-containing tungsten carbide spraying powder used for preparing self-lubricating abrasion-resistant coating

A technology of spraying powder and wear-resistant coating, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., and can solve the problems of easy agglomeration, retention of graphene components, high activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the present invention, first carry out the preparation of modified graphene (graphene modified tungsten carbide self-lubricating wear-resistant additive) The preparation process is as follows:

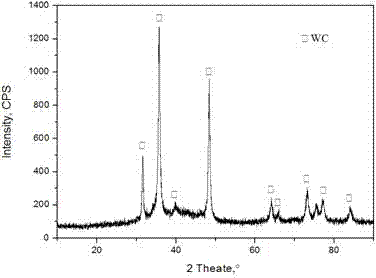

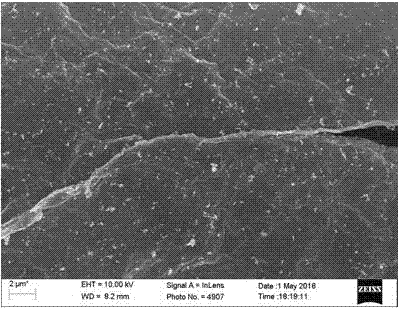

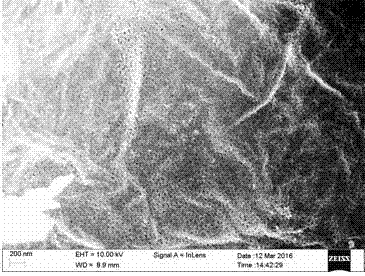

[0029] Weigh 1g of graphene oxide, add 1000g of absolute ethanol, stir and mix evenly, add 50g of deionized water for mixing, in an ultrasonic disperser, select a 10mm amplitude rod, ultrasonic treatment time is 30min, and ultrasonic frequency is 10Hz to obtain graphite Graphene dispersion mixed solution, respectively weighed 99% of the mass percentage of ammonium metatungstate and 1% of tungsten carbonyl to mix into a tungsten-containing precursor mixture, weighed 1g of the tungsten-containing precursor mixture was added to the graphene dispersion solution, Stir for 30 minutes. During the stirring process, add absolute ethanol continuously, and the drop amount is 18g. Then filter the obtained precipitate with suction, heat in an oven at 70°C, and dry for 10 minutes. Put the obt...

Embodiment 2

[0041] On the basis of the above examples, further, in this example, the preparation process of modified graphene (that is, graphene modified tungsten carbide self-lubricating wear-resistant additive) is as follows:

[0042] Weigh 2g of graphene oxide, add 1000g of absolute ethanol, stir and mix evenly, add 60g of deionized water for mixing, in an ultrasonic disperser, select a 10mm amplitude rod, ultrasonic treatment time is 60min, and ultrasonic frequency is 12Hz to obtain graphite Graphene dispersion mixed solution, respectively weighed 99% of the mass percentage of ammonium metatungstate and 1% of tungsten carbonyl to mix into a tungsten-containing precursor mixture, weighed 1g of the tungsten-containing precursor mixture was added to the graphene dispersion solution, Stir for 40 minutes. During the stirring process, add absolute ethanol continuously. The dropping amount is 84g. Then filter the obtained precipitate with suction, heat in an oven at 80°C, and dry for 20 minut...

Embodiment 3

[0049] On the basis of the above examples, further, in this example, the preparation process of modified graphene (graphene modified tungsten carbide self-lubricating wear-resistant additive) is as follows:

[0050] Weigh 3g of graphene oxide, add 1000g of absolute ethanol, stir and mix evenly, add 700g of deionized water for mixing, in an ultrasonic disperser, select a 10mm amplitude rod, ultrasonic treatment time is 120min, and ultrasonic frequency is 12Hz to obtain graphite Graphene dispersion mixed solution, respectively weighed 99% of the mass percentage of ammonium metatungstate and 1% of tungsten carbonyl to mix into a tungsten-containing precursor mixture, weighed 1g of the tungsten-containing precursor mixture was added to the graphene dispersion solution, Stir for 50 minutes. During the stirring process, add absolute ethanol continuously, and the amount of dropping is 168g. Then filter the obtained precipitate with suction, heat in an oven at 80°C, and dry for 20 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com