Basalt needling thermal insulation material and manufacturing process thereof

A thermal insulation, basalt technology, used in textiles, papermaking, non-woven fabrics, etc., can solve problems such as low hygroscopicity, achieve high breaking strength, improve production efficiency, and reduce the number of downtimes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The basalt thermal insulation material is made of chopped basalt yarns with a length of 7 cm and a length of 12 cm through mixing, opening, carding, net laying and acupuncture; wherein the chopped basalt yarns with a length of 7 cm account for the total amount of materials. 70% of the mass, basalt chopped strands with a length of 12cm accounted for 30% of the total mass of the material;

[0060] And made by the following steps:

[0061] (1) Mixing: After mixing the two kinds of basalt chopped strands with a mixer, stir in the material box to make the two kinds of chopped strands fully mixed and fluffy; the mixing time is 0.5 hours, and the rocker arm speed is at 30~50 rev / min;

[0062] (2) Opening: use an opening machine to open the chopped yarn mixed in step (1) to form a single fiber, and put it into a hopper;

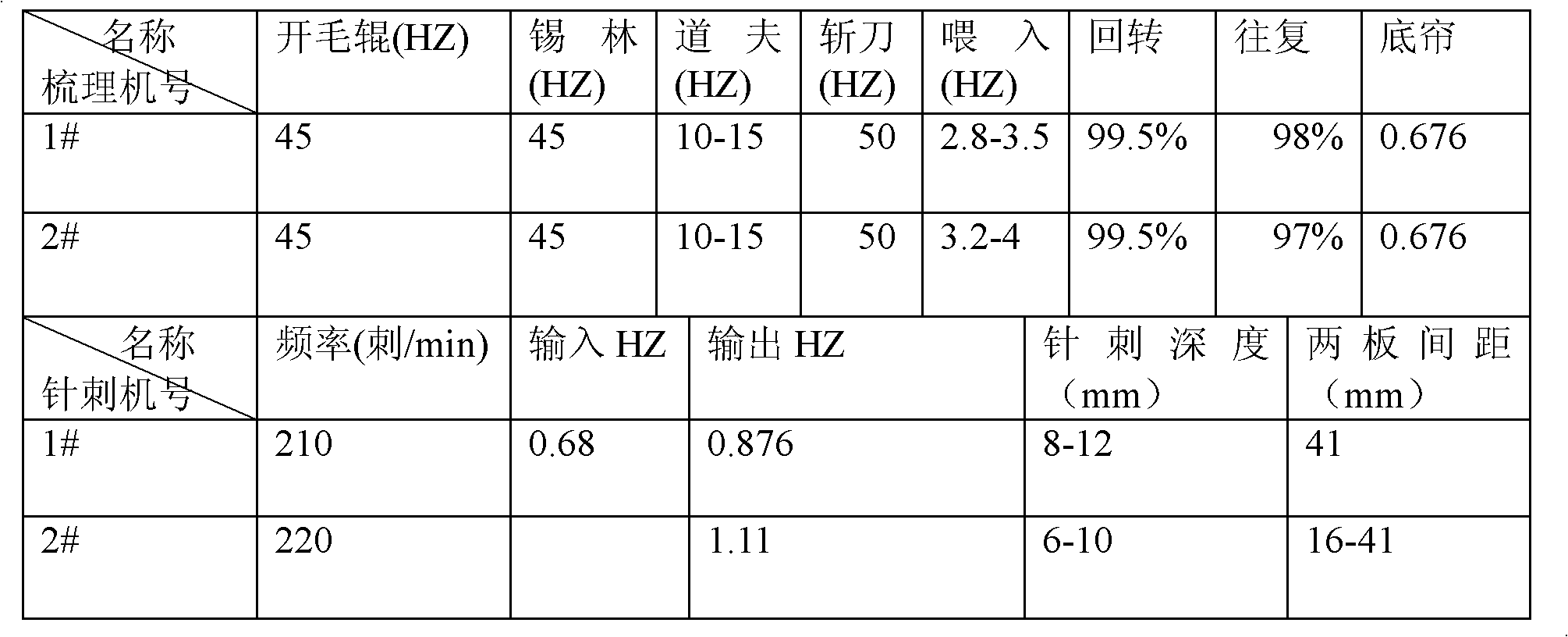

[0063] (3) Carding: Two carding machines comb the fibers in the material box out of the net, and the basalt fiber that has been loosened in step (2) is made...

Embodiment 2

[0072] The basalt thermal insulation material is made of chopped basalt yarns with a length of 7 cm and a length of 12 cm through mixing, opening, carding, net laying and acupuncture; wherein the chopped basalt yarns with a length of 7 cm account for the total amount of materials. 75% of the mass, basalt chopped strands with a length of 12cm accounted for 25% of the total mass of the material;

[0073] And made by the following steps:

[0074] (1) Mixing: After mixing the two kinds of basalt chopped strands with a mixer, stir in the feed box to make the two kinds of chopped strands fully mixed and fluffy; the mixing time is 0.8 hours, and the rocker arm speed is at 30~50 rev / min;

[0075] (2) Opening: use an opening machine to open the chopped yarn mixed in step (1) to form a single fiber, and put it into a hopper;

[0076] (3) Carding: Two carding machines comb the fibers in the material box out of the net, and the basalt fiber that has been loosened in step (2) is made int...

Embodiment 3

[0085] The basalt thermal insulation material is made of chopped basalt yarns with a length of 7 cm and a length of 12 cm through mixing, opening, carding, net laying and acupuncture; wherein the chopped basalt yarns with a length of 7 cm account for the total amount of materials. 80% of the mass, basalt chopped strands with a length of 12cm accounted for 20% of the total mass of the material;

[0086] And made by the following steps:

[0087] (1) Mixing: After mixing the two kinds of basalt chopped strands with a mixer, stir them in the material box, so that the two kinds of chopped strands are fully mixed and fluffy; the mixing time is 0.6 hours, and the rocker arm speed is at 30~50 rev / min;

[0088] (2) Opening: use an opening machine to open the chopped yarn mixed in step (1) to form a single fiber, and put it into a hopper;

[0089] (3) Carding: Two carding machines comb the fibers in the material box out of the net, and the basalt fiber that has been loosened in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com