A method of manufacturing a circuit board with stepped grooves

A manufacturing method and step groove technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems that gaskets are not easy to remove, difficult to remove, and easy to delaminate around, so as to avoid difficult removal and avoid Easy to layer and avoid the effect of gasket residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

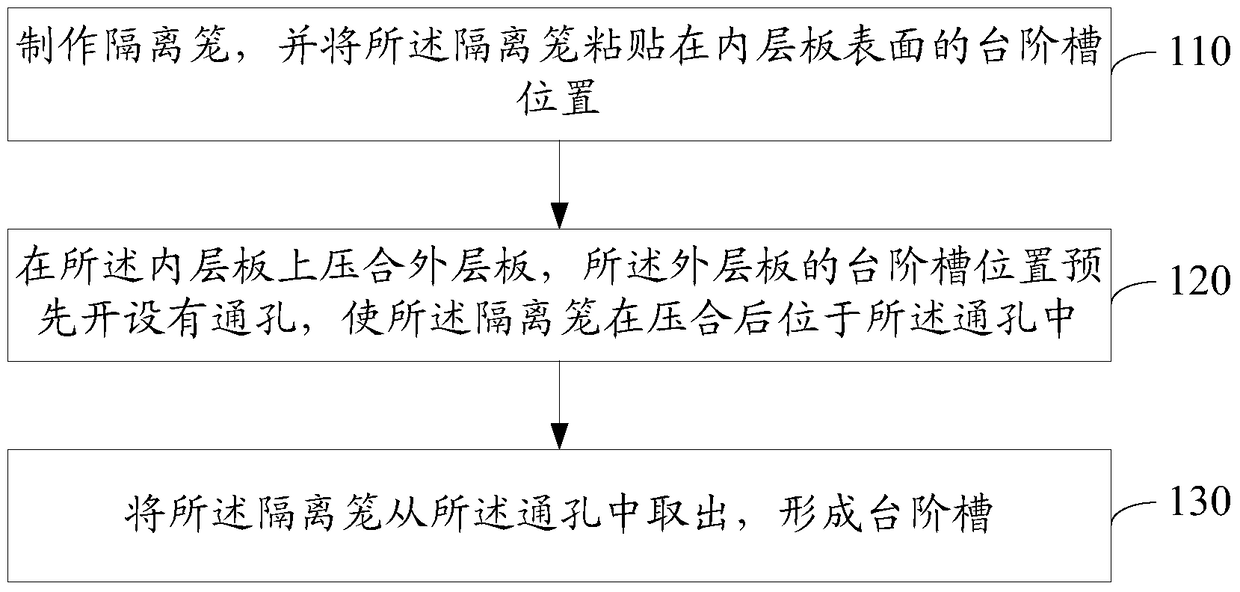

[0016] Please refer to figure 1 , an embodiment of the present invention provides a method for manufacturing a circuit board with stepped grooves, the method comprising:

[0017] 110. Make an isolation cage, and paste the isolation cage at the step groove position on the surface of the inner layer board.

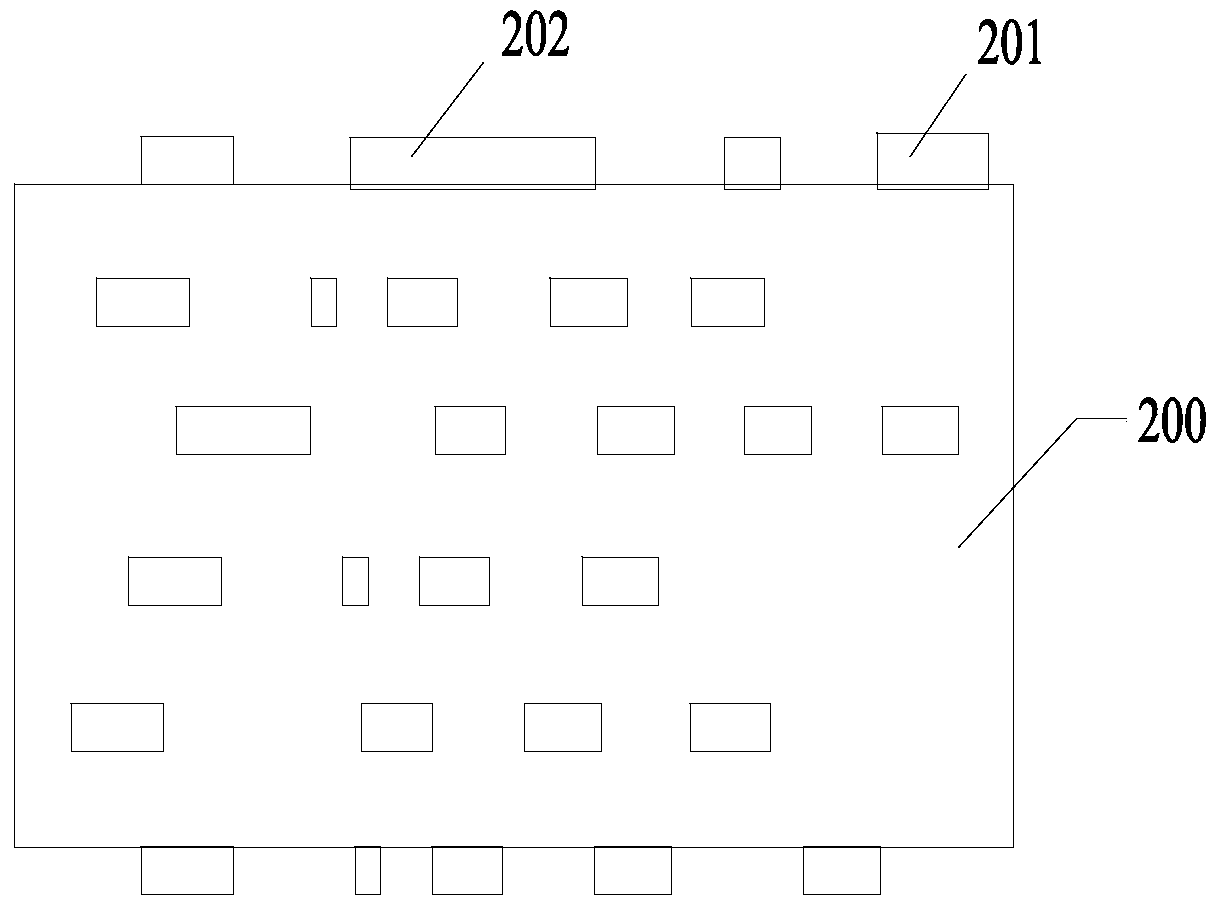

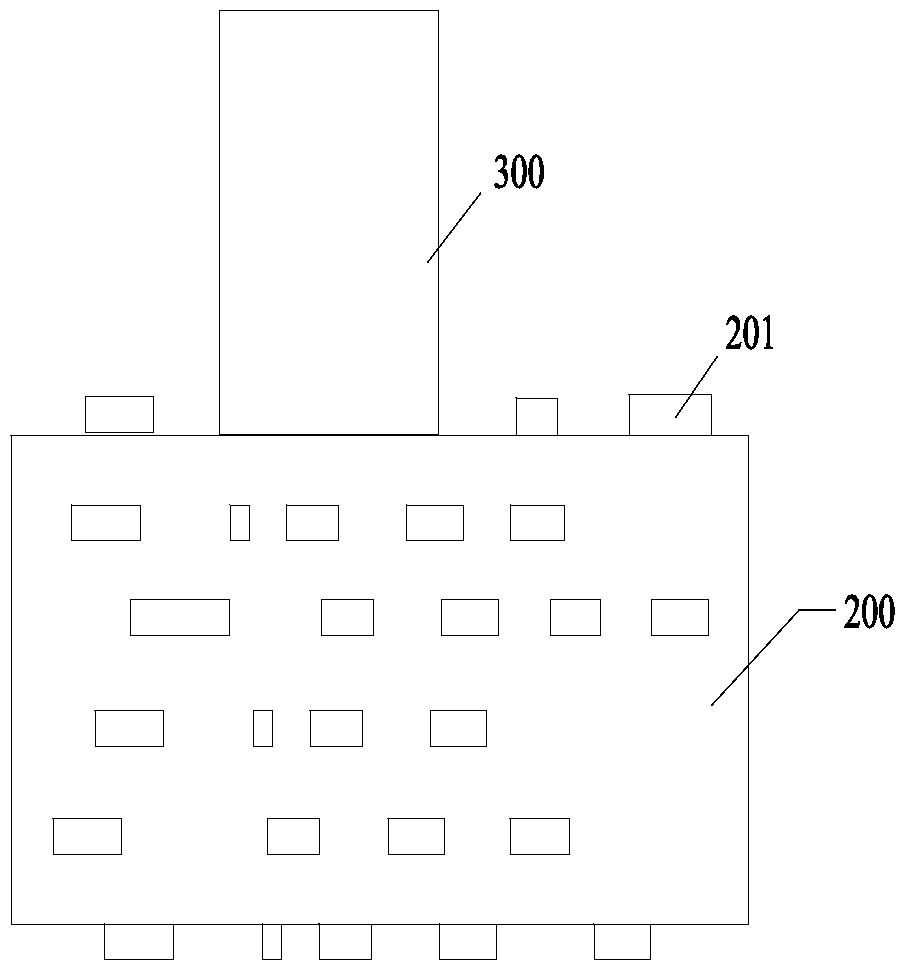

[0018] The inner board mentioned in this embodiment may specifically be a double-sided copper-clad board or a multi-layer board. Such as figure 2 As shown, the inner layer circuit pattern 201 can be processed on the surface of the inner layer board 200 using a conventional circuit pattern manufacturing process. The said stepped groove position 202 will subsequently become the bottom surface of the stepped groove, and the solder pad at this position will be used to connect the electronic components subsequently mounted in the stepped groove.

[0019] In some implementation manners, the pads at the stepped groove positions 202 may be surface-coated as required. The so-cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com