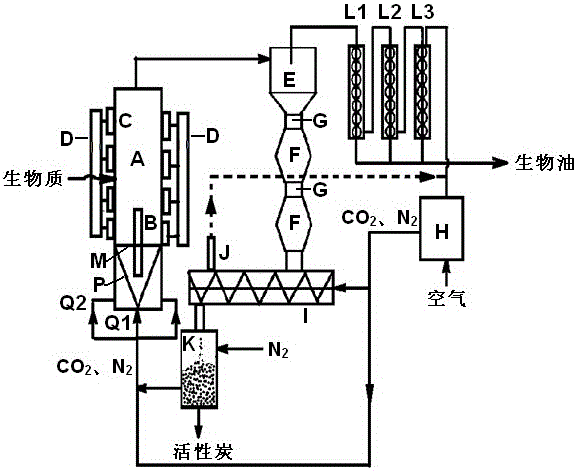

A system for preparing bio-oil and activated carbon by microwave pyrolysis

A technology of activated carbon and bio-oil, which is applied in the fields of bio-fuel, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of complicated process, complicated equipment, affecting the yield of bio-oil, etc., achieves short activation temperature, overcomes small particle size, and accelerates The effect of separating the bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Turn on the microwave generator D (10 microwave windows) leading to the spouted fluidized bed, and the microwave power density is 10×10 5 W / m 3 , from the jet gas inlet Q1 and the fluidization gas inlet Q2 respectively introduce the jet gas (the jet gas is derived from the gas guide pipe B), the fluidization gas (through the gas distribution plate M, the hole diameter is 0.2mm, and the opening ratio is 10%) so that The bed material in the reactor is in a state of partial spray fluidization, the fluidization gas velocity is 0.1m / s, and the spray gas velocity is 0.15m / s. Sawdust (5mm) is sent into the reactor to conduct heat and mass transfer with silicon carbide, so that the temperature of reactor A reaches the pyrolysis temperature of 500°C. At this time, the jet gas velocity is adjusted to 0.3m / s, and the microwave power density is reduced to 5× 10 5 W / m 3 . After the temperature reaches equilibrium, the sawdust raw material is sent into the guided spouted fluidize...

Embodiment 2

[0039] Turn on the microwave generator D (10 microwave windows) leading to the spouted fluidized bed, and the microwave power density is 10×10 5 W / m 3 , from the injection gas inlet Q1 and the fluidization gas inlet Q2 (the injection gas is derived from the gas guide pipe B), the fluidization gas (through the gas distribution plate M, the hole diameter is 0.2mm, and the opening ratio is 10%) to make the reactor inside The bed material is in the state of partial spray fluidization, the fluidization gas velocity is 0.15m / s, and the spray gas velocity is 0.25m / s. ) into the reactor to conduct heat and mass transfer with silicon nitride so that the temperature of reactor A reaches the pyrolysis temperature of 550°C. 5 W / m 3 . After the temperature reaches equilibrium, the sawdust raw material is sent into the guided spouted fluidized bed by screw propulsion, so that the biomass raw material is rapidly pyrolyzed by heat, and the pyrolysis gas and part of the coke produced are ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com