A method of manufacturing a stepped circuit board

A circuit board manufacturing and ladder technology, applied in the directions of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of difficult to clean, easy delamination of circuit boards, and difficult removal of gaskets, so as to avoid easy delamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

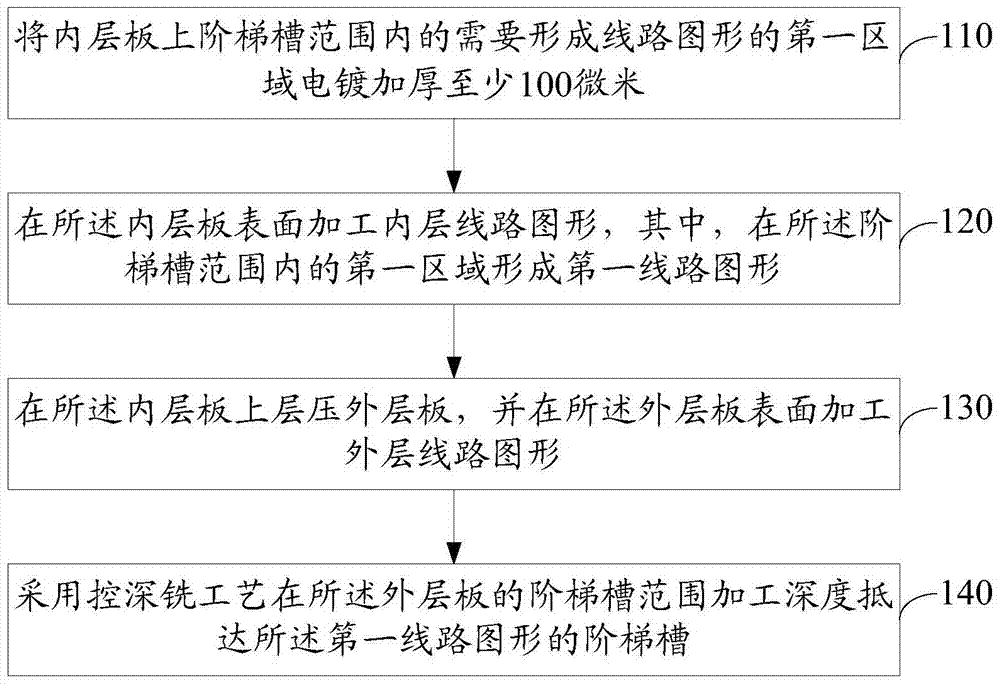

[0016] Please refer to figure 1 , an embodiment of the present invention provides a method for manufacturing a stepped circuit board, including:

[0017] 110. Thicken the first area of the inner layer board where the circuit pattern needs to be formed by electroplating at least 100 microns.

[0018] The inner board can be a double-sided copper-clad board, or a laminated multi-layer board. This article takes double-sided copper clad laminate as an example to illustrate. The bottom of the stepped groove to be formed later will reach the surface of the inner layer board.

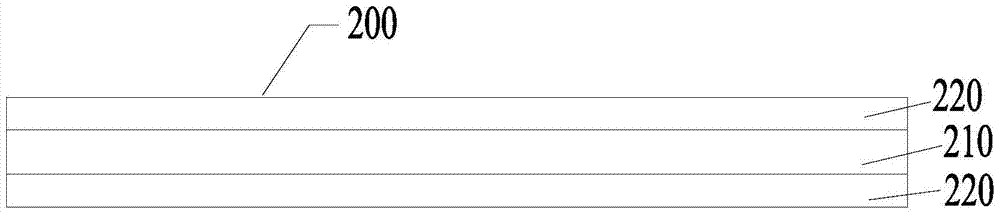

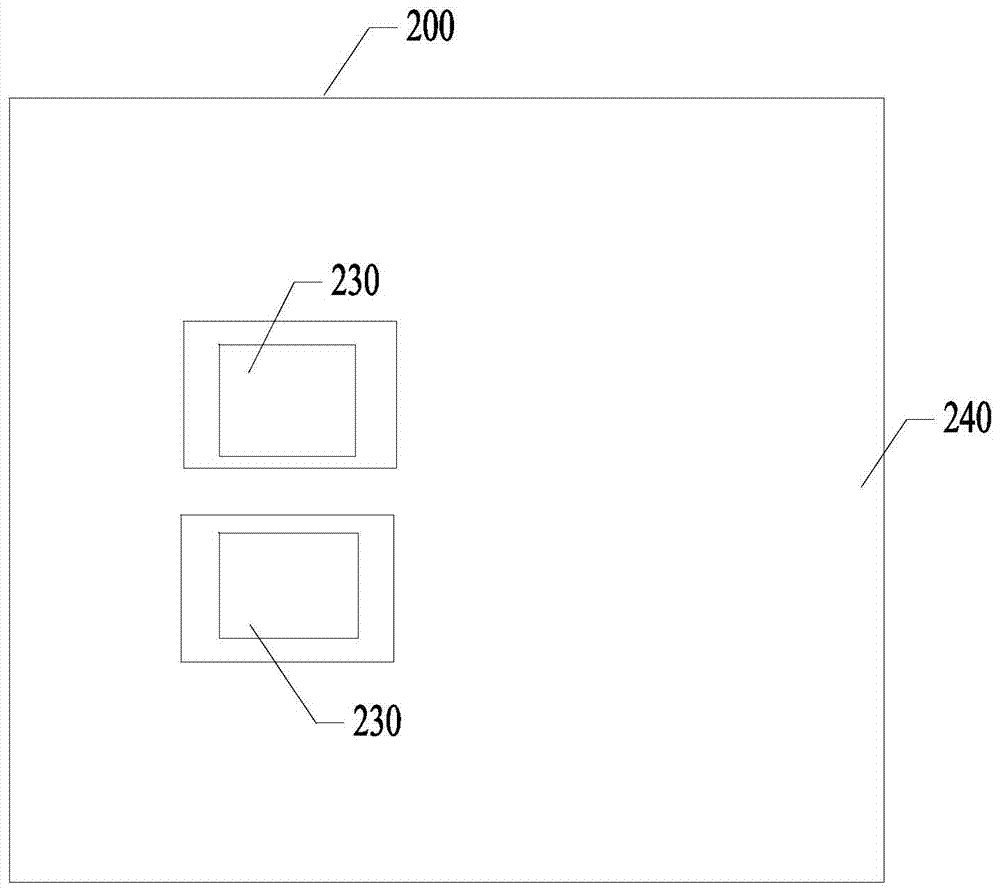

[0019] Such as Figure 2a As shown, the inner board 200 includes a core board layer 210 in the middle and copper foil layers 220 on both sides. Such as Figure 2b As shown, the surface of the inner plate 200 can be divided into two parts, one is the range 230 of the stepped groove, and the other is the range 240 other than the stepped groove.

[0020] In this embodiment, before processing the circuit pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com