A kind of asphalt emulsifier and preparation method thereof

An asphalt emulsifier and catalyst technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of limited emulsifying ability and poor stability of emulsified asphalt, and achieve simple preparation method, strong emulsifying ability, and avoid modification and easy separation. layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

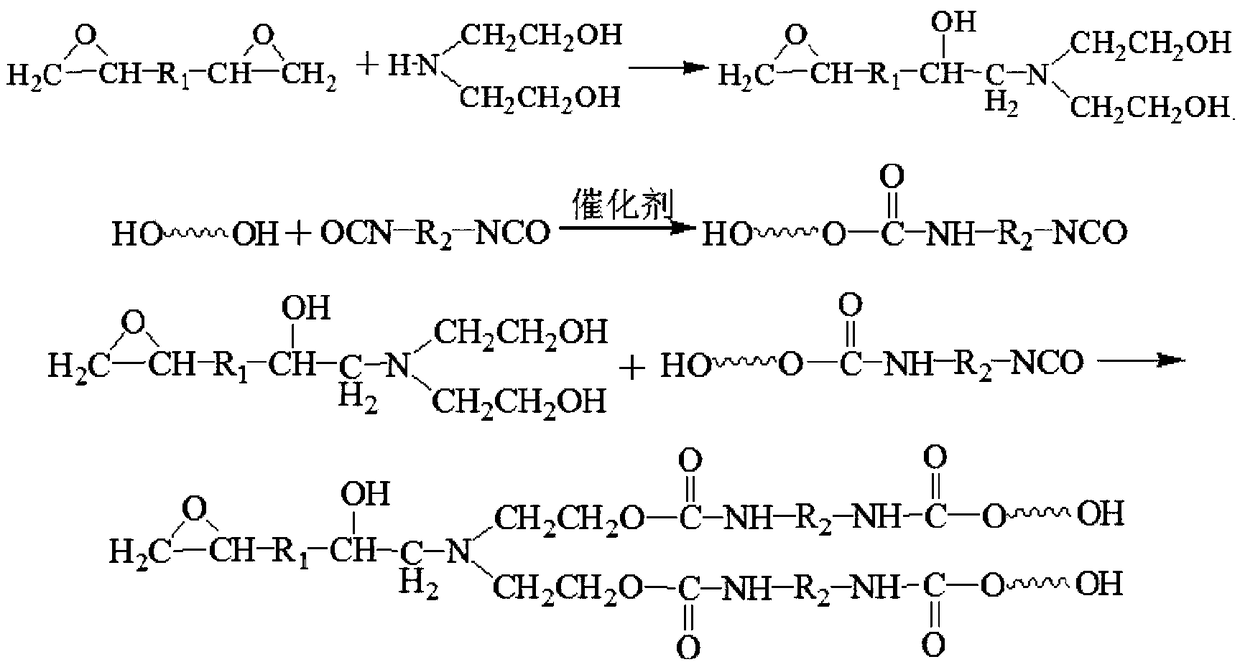

Method used

Image

Examples

Embodiment 1

[0024] Preparation of emulsifier: (1) Dissolve 0.1mol of bisphenol A epoxy resin E-51 with 50ml of acetone at 40°C, then slowly add 0.1mol of diethanolamine dropwise, then raise the temperature to 80°C and react for 2h to obtain di Epoxy resin E-51 modified by ethanolamine; (2) Add 0.2mol MDI to 0.2mol PEG-200 and 1.8g stannous octoate, and react for 2 hours under nitrogen protection at 40°C to obtain a polyurethane prepolymer; Diethanolamine-modified epoxy resin E-51 was slowly added dropwise to the polyurethane prepolymer, reacted at 50°C for 1 hour, and then heated to 70°C for 2 hours to obtain an asphalt emulsifier.

[0025] Preparation of emulsified asphalt: First weigh 20g of the above emulsifier and add 200g of warm water at 55°C to dissolve it, then add water to 350g, add dilute hydrochloric acid to about pH=2, and finally add water to 400g to obtain soap liquid; then take SK90# asphalt Heat 600g to 140°C, heat the above 400g soap solution to 60°C, mix the asphalt and ...

Embodiment 2

[0031] Preparation of emulsifier: (1) Dissolve 0.1mol of bisphenol A epoxy resin E-54 with 50ml of toluene at 60°C, then slowly add 0.1mol of diethanolamine dropwise, then raise the temperature to 80°C for 3 hours to obtain di Epoxy resin E-54 modified by ethanolamine; (2) 0.2mol TDI was added to 0.2mol PEG-400 and 2.3g stannous octoate, and reacted for 3h under nitrogen protection at 50°C to obtain a polyurethane prepolymer; Diethanolamine-modified epoxy resin E-54 was slowly added dropwise to the polyurethane prepolymer, reacted at 60°C for 2 hours, and then heated to 80°C for 2 hours to obtain an asphalt emulsifier.

[0032] Preparation of emulsified asphalt: First weigh 20g of the above emulsifier and add 200g of warm water at 55°C to dissolve it, then add water to 350g, add dilute hydrochloric acid to about pH=2, and finally add water to 400g to obtain soap liquid; then take SK90# asphalt Heat 600g to 140°C, heat the above 400g soap solution to 60°C, mix the asphalt and s...

Embodiment 3

[0038] Preparation of emulsifier: (1) Dissolve 0.1mol of bisphenol A epoxy resin E-44 with 50ml of xylene at 60°C, then slowly add 0.11mol of diethanolamine dropwise, then heat up to 90°C and react for 4 hours to obtain Diethanolamine-modified epoxy resin E-44; (2) 0.22mol MDI was added to 0.22mol PEG-400 and 2.6g stannous octoate, and reacted for 4h under nitrogen protection at 50°C to obtain a polyurethane prepolymer; The above-mentioned diethanolamine-modified epoxy resin E-44 was slowly added dropwise to the polyurethane prepolymer, reacted at 50°C for 2 hours, and then heated to 70°C for 2 hours to obtain an asphalt emulsifier.

[0039]Preparation of emulsified asphalt: First weigh 20g of the above emulsifier and add 200g of warm water at 55°C to dissolve it, then add water to 350g, add dilute hydrochloric acid to about pH=2, and finally add water to 400g to obtain soap liquid; then take SK90# asphalt Heat 600g to 140°C, heat the above 400g soap solution to 60°C, mix the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Marshall stability | aaaaa | aaaaa |

| Marshall stability | aaaaa | aaaaa |

| Marshall stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com