Rotary spray paint multi-layer device

A technology of rotating drum and rotating shaft, applied in the direction of spraying device, etc., can solve the problems of different paint humidity and easy delamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

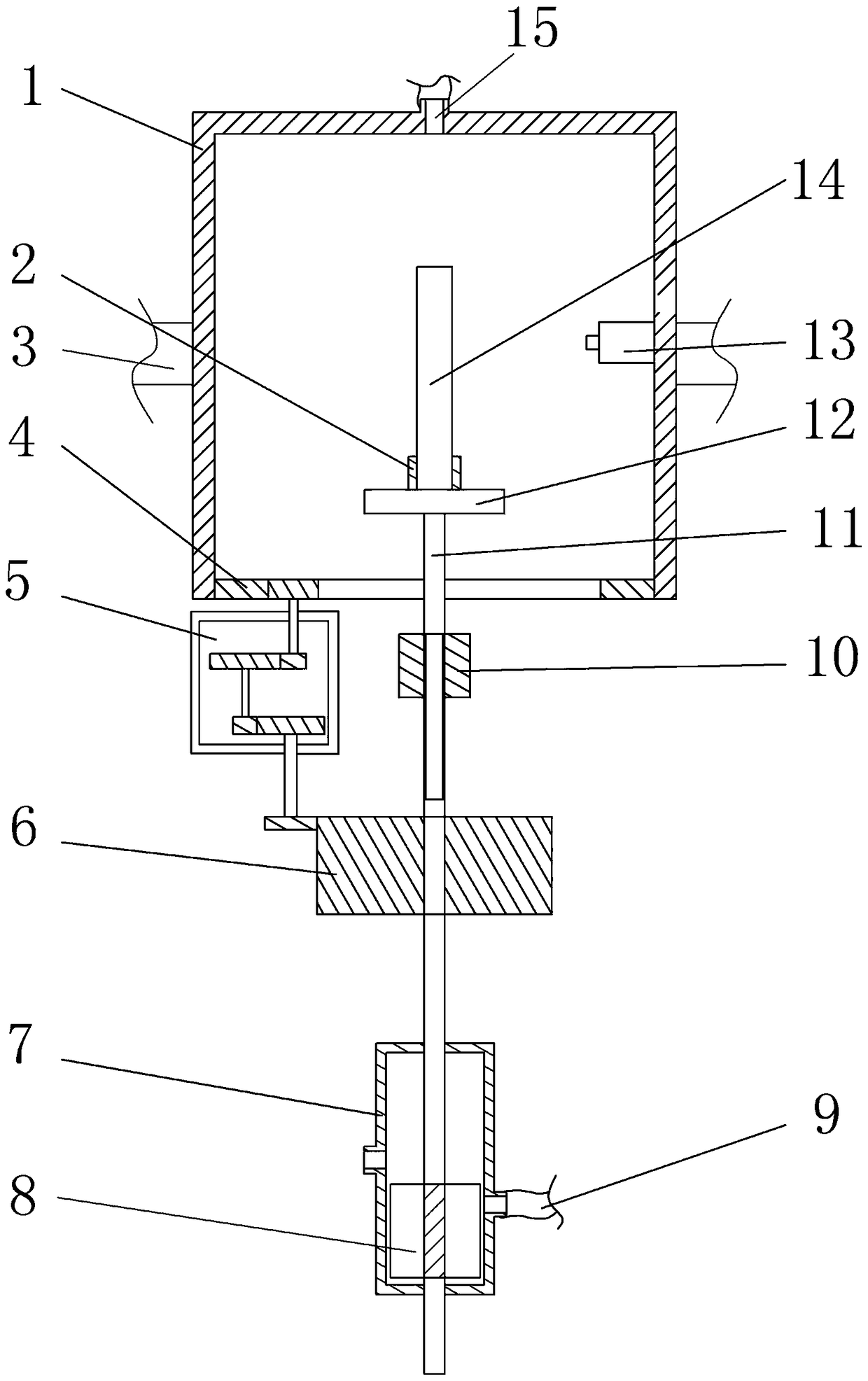

[0016] Embodiment: The multi-layer device for rotating paint spraying in this program includes a support 3, an air pump, a fixed seat 10, a gear acceleration mechanism, a rotating drum 1 and a sealed casing 7, and the fixed seat 10 is threadedly connected with a rotating shaft 11, and the rotating shaft 11 is connected in rotation On the two side walls of the housing 7, the rotating shaft 11 is welded with clamps and blades, and the key is connected with the power gear 6. The clamp includes a clamp seat 12 and two splints 2. The threaded connection has an adjusting screw. The blades are plates 8 vertically evenly distributed on the rotating shaft 11, the blades are located in the casing 7, the casing 7 is welded with an air inlet pipe 9, and the casing 7 is integrally formed with an air outlet; the top of the drum 1 is closed, and the drum 1 1 is rotatably connected to the bracket 3, the outer wall of the drum 1 is equipped with a door for entering and exiting, the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com