Device for cutting glass substrate and its method

A technology of cutting equipment and cutting method, which is applied in the direction of metal processing equipment, welding equipment, glass manufacturing equipment, etc., and can solve the problems of misalignment of cutting surfaces, inability to accurately control the cutting depth of glass substrates, and lower product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Like reference numerals refer to like elements throughout the drawings of the specification.

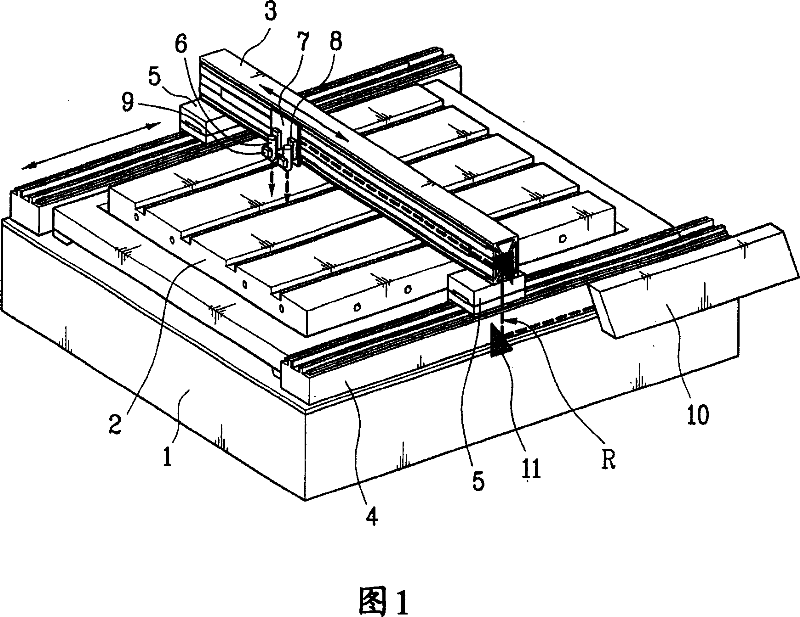

[0033] FIG. 1 is a perspective view of a non-metallic substrate cutting apparatus for manufacturing a flat panel display according to one embodiment of the present invention.

[0034]Referring to FIG. 1, a non-metallic substrate cutting device for manufacturing a flat panel display according to an embodiment of the present invention includes: a workbench 2, which is arranged on a central portion of a base 1 to support a glass substrate (not shown in the drawings) ; The front and rear guide columns 4 are respectively arranged on both sides of the workbench 2 ;

[0035] Left and right guide columns 3 are arranged on each pusher 5 to guide a laser head 6 to move in left and right directions. Moreover, the left and right guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com