laser cutting machine

A cutting machine and laser technology, applied in the direction of welding/cutting auxiliary equipment, auxiliary devices, laser welding equipment, etc., can solve the problems of easy damage to internal wires, low production efficiency, and partial stripping of waste materials, so as to avoid damage to the inside of wires and production The effect of high efficiency and reduced defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

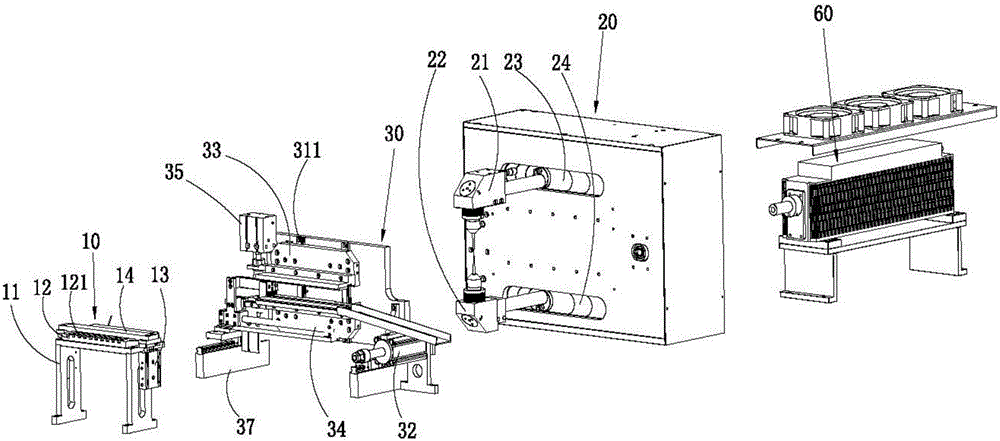

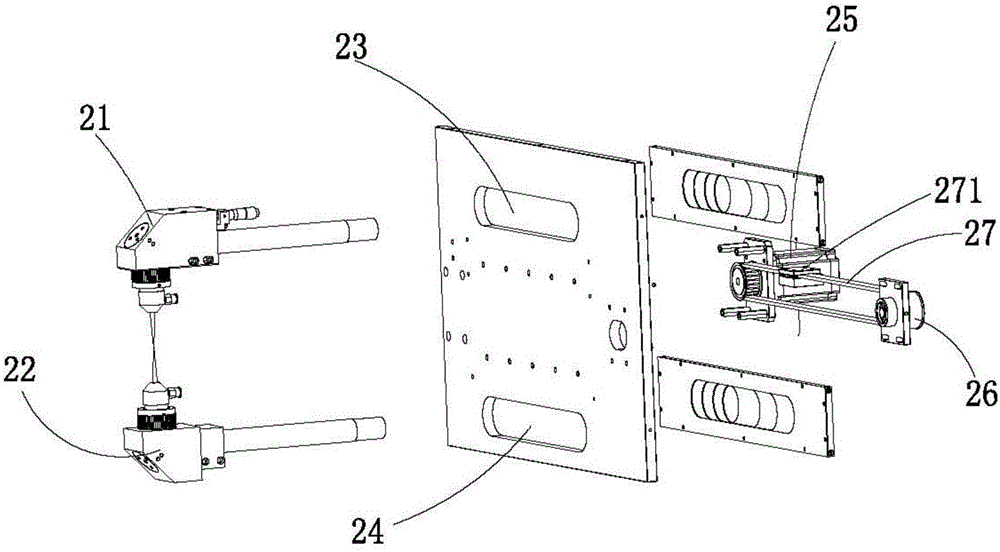

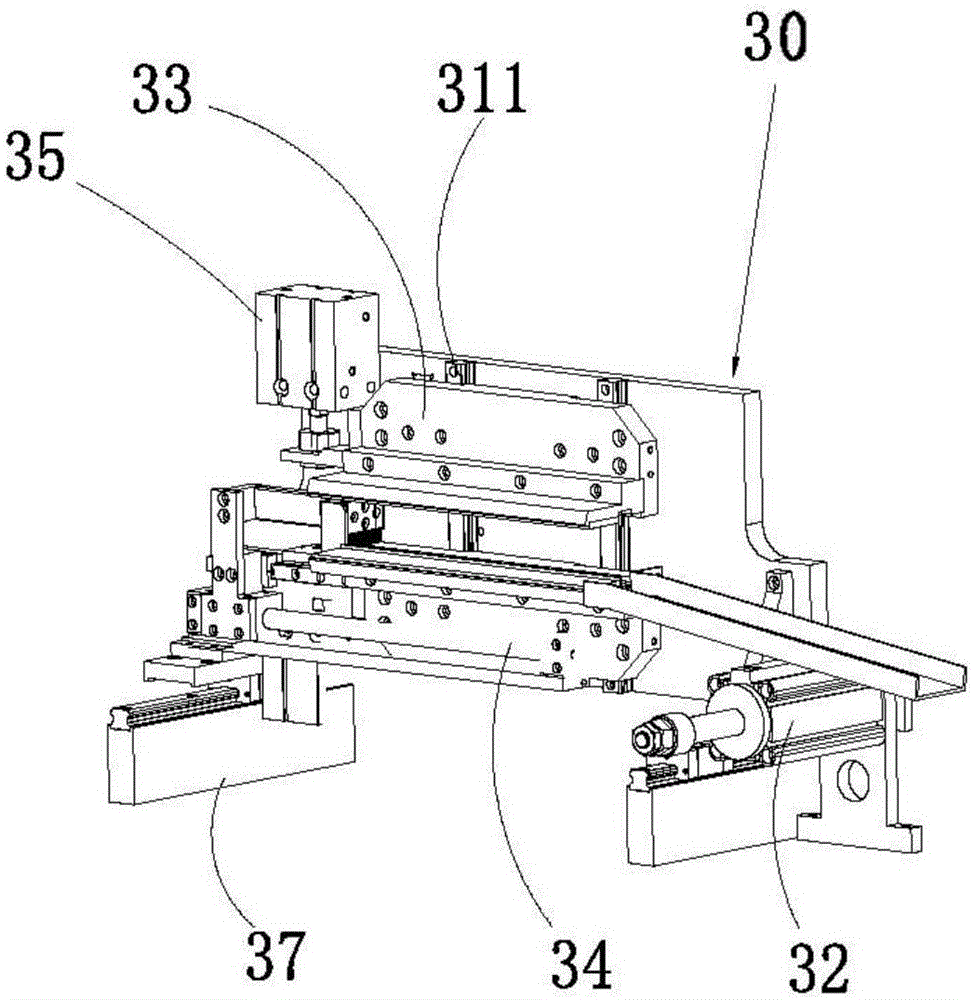

[0022] see figure 1 , the present invention discloses a laser cutting machine, which includes a stage 10 for placing wires, an X-axis cutting device 20 , a bending and shifting device 30 and a laser 60 . The X-axis cutting device 20 has an upper laser head 21 and a lower laser head 22 , and the laser light emitted by the laser 60 is transmitted to the upper laser head 21 and the lower laser head 22 through the optical path mechanism.

[0023] Please also refer to figure 2 , the X-axis cutting device 20 is provided with a first chute 23 and a second chute 24 , and the first chute 23 is parallel to the second chute 24 . The upper laser head 21 is set to slide on the first chute 23 and is located above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com