Tool holder device of adjustable type diamond knife tool

A diamond tool and adjustable technology, which is applied to fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of inability to adjust the tool angle, increase costs, low work efficiency, etc., and achieve compact structure and reduce tool replacement. time, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

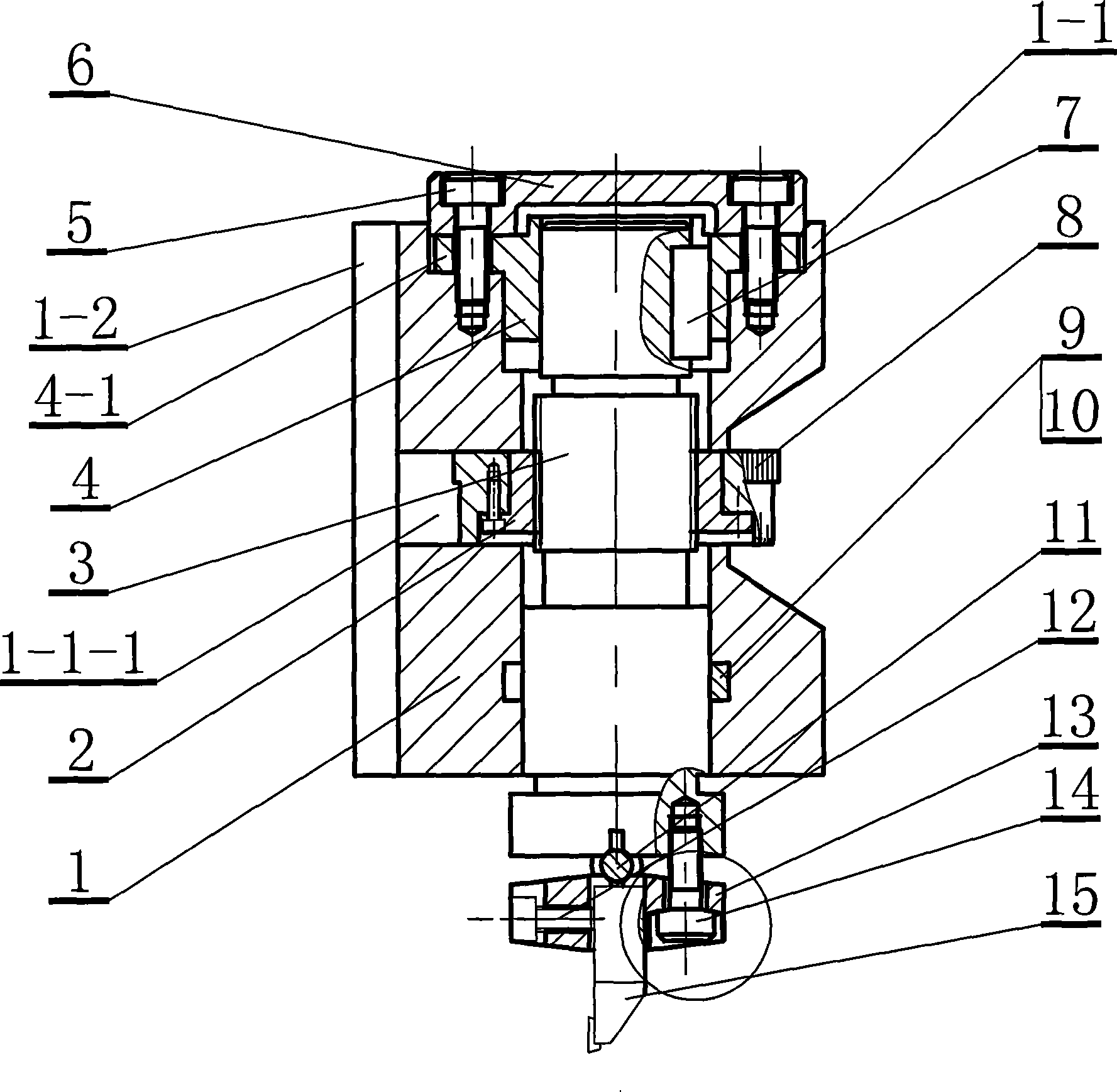

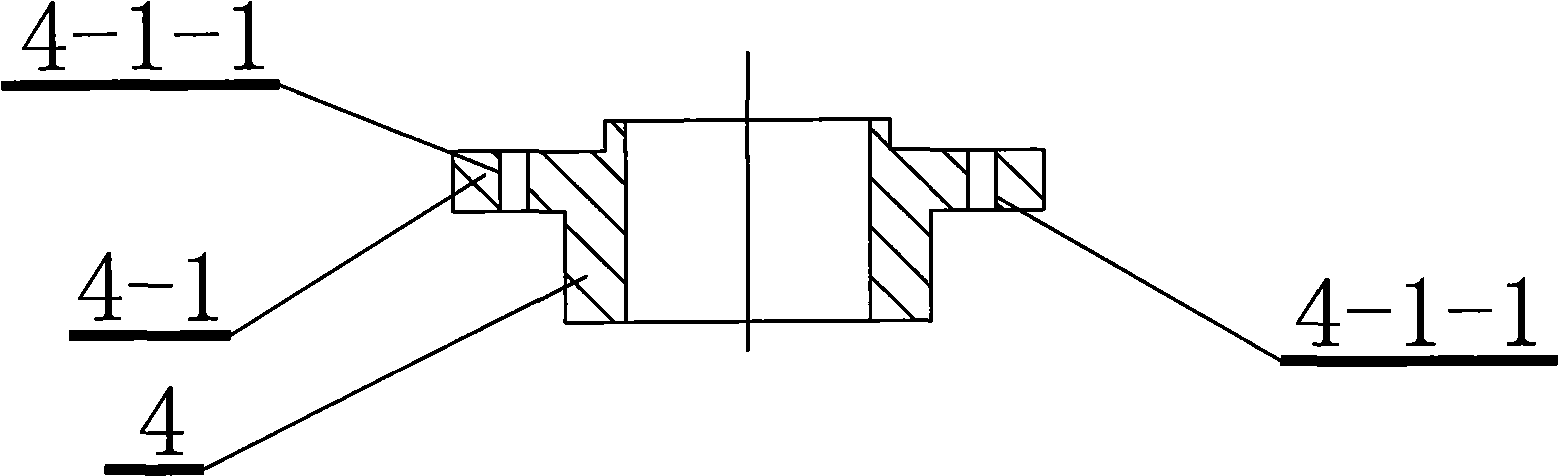

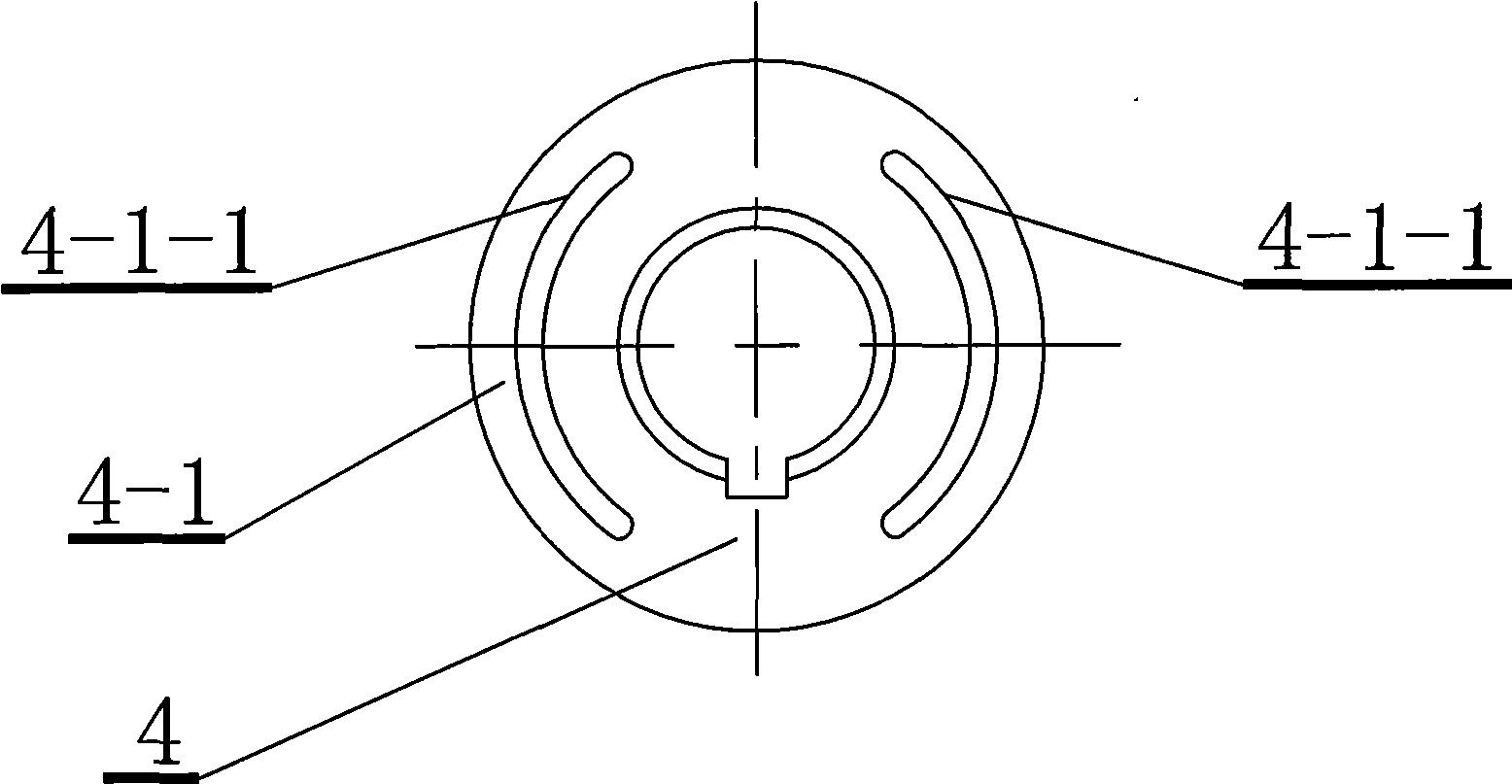

[0008] Specific implementation mode one: as Figure 1~5 As shown, the tool holder device of the adjustable diamond tool described in this embodiment consists of a tool holder main body 1, a screw inner sleeve 2, a fine-tuning screw shaft 3, an indexing guide sleeve 4, two screws 5, and an end cover 6 , guide key 7, fine-tuning handwheel 8, lock ring 9, lock nut 10, swing support shaft 11, tool holder seat 13 and four indexing adjustment screws 14, and the tool holder main body 1 is composed of a cylinder 1- 1 and a connecting plate 1-2, the left side wall of the cylinder 1-1 is fixedly connected to one side end surface of the connecting plate 1-2, and the outer edge 4-1 of the indexing guide sleeve 4 is symmetrical There are two arc-shaped through holes 4-1-1, the indexing guide sleeve 4 is installed on the upper end of the fine-tuning screw shaft 3 through the guide key 7, and the inner sleeve 2 of the screw is set on the top of the fine-tuning screw shaft 3 The middle part ...

specific Embodiment approach 2

[0009] Specific implementation mode two: as figure 1 with Figure 4 As shown, in this embodiment, the corresponding position of the tool holder seat 13 that is in contact with the upper end surface of the screw head of the index adjustment screw 14 is set as a ball-and-socket surface. Such setting can improve the locking force between the index adjustment screw 14 and the fine adjustment screw shaft 13 . Other compositions and connections are the same as in the first embodiment.

[0010] Working principle: install the tool holder body 1 on the cutter head of the processing machine tool, the diamond tool 15 is installed on the tool holder seat 13 by the locking screw 12, and there is a certain gap between the upper end of the diamond tool 15 and the swing support shaft 11 , adjust the four indexing adjustment screws 14 on the toolholder 13, so that the toolholder rotates around the swing support shaft 11, the diamond tool 15 and the toolholder 13 rotate around the swing suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com