Dry-grinding diamond grinding wheel

A diamond and diamond cutter head technology, applied in abrasives, grinding devices, bonded grinding wheels, etc., can solve the problems of violent collision, destroy cutter head, reduce grinding efficiency, etc., to reduce the probability of collision, accelerate gas circulation, mechanical The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

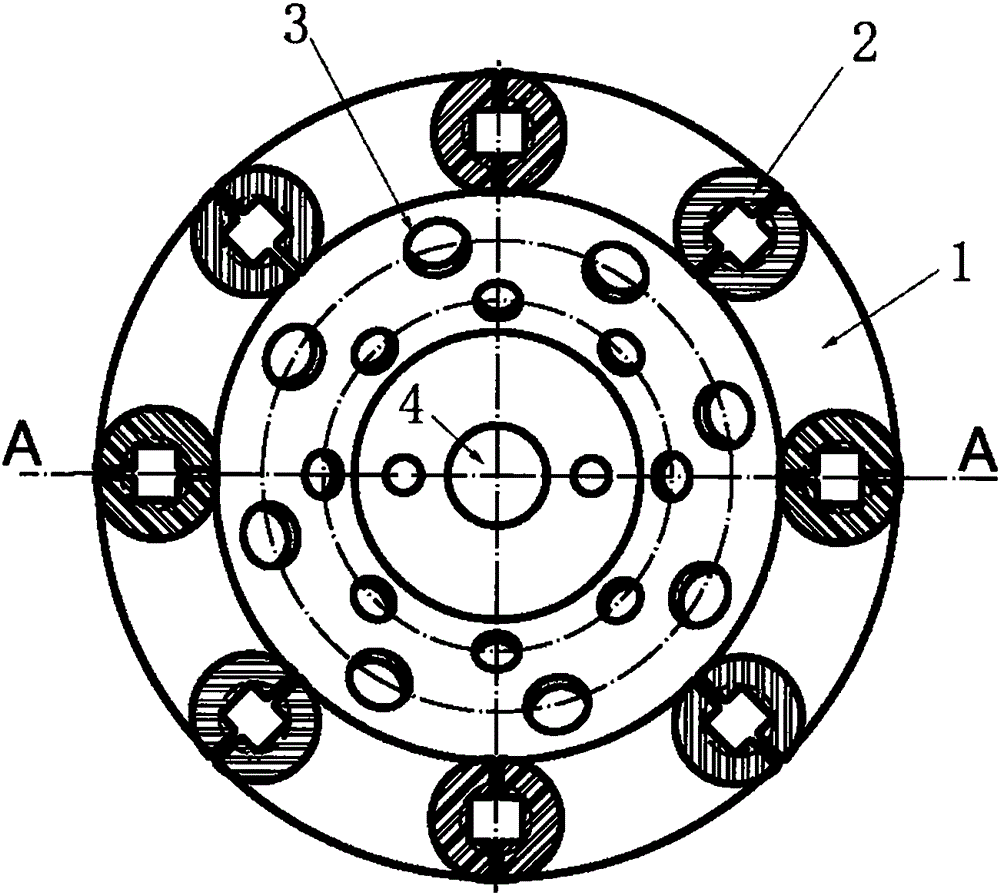

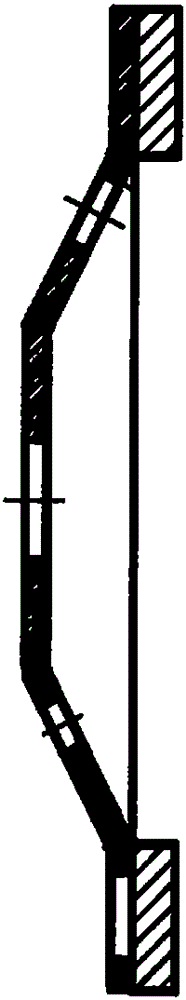

[0022] The present invention is the preparation technology of dry grinding diamond grinding wheel, as Figure 1-2 As shown, the diamond grinding wheel comprises a grinding wheel base 1 and a diamond cutter head 2 arranged on the grinding wheel base 1; its preferred structure is as follows:

[0023] The grinding wheel base 1 is designed to be disc-shaped, and the outer edge of the grinding wheel base is an annular plane; the diamond cutter head 2 is multiple, and is evenly distributed on the annular plane of the grinding wheel base; the center position of the disc-shaped grinding wheel base is A shaft hole 4 for fixing the base body of the grinding wheel is provided.

[0024] Described diamond cutter head is the circular cake shape structure that square through hole 3 is opened in the middle part, and annular heat dissipation hole is opened on the annular plane of grinding wheel base simultaneously, and the opening position of annular heat dissipation hole is the same as the po...

Embodiment 1

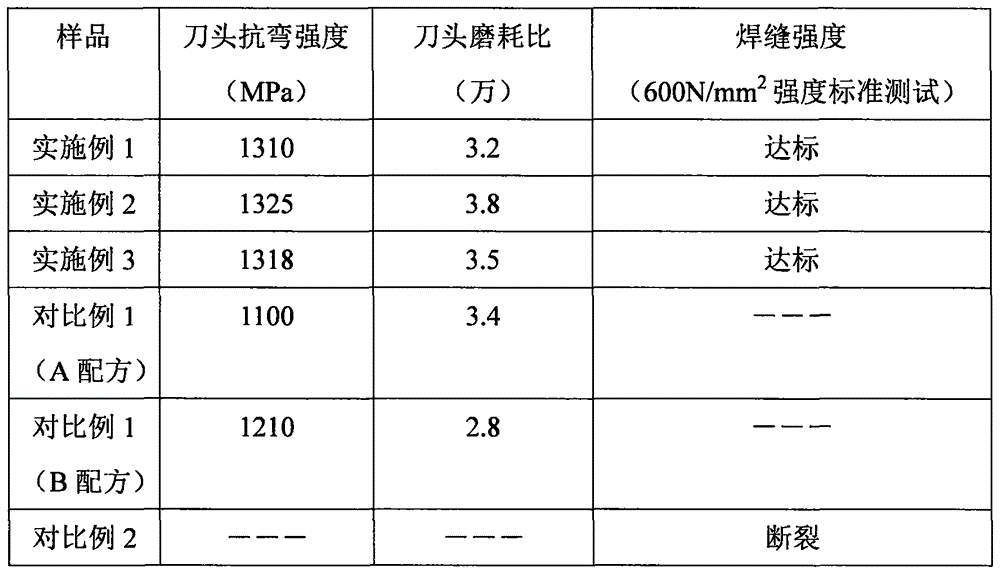

[0036] The raw materials of the diamond cutter head are: copper powder 3.0kg, iron 3.8kg, nickel 0.83kg, cobalt 1.8kg, tin 0.12kg and rare earth element (Ce) 0.14kg, put into the mixing tank and mix for 30 minutes, add liquid paraffin 0.13 kg and diamond (30 / 40 mesh, compressive strength 30kg) 0.18kg, after 3 hours of continuous mixing, the powder is poured into the mold for cold pressing, hot pressing and sintering, the grinding wheel abrasive belt is used to grind the cutter head, and the cutter head and Put the silver soldering piece together on the corresponding substrate position according to the requirements of the drawing, adjust the welding position and heat and melt the silver soldering piece, so that the cutter head and the substrate are welded together, and then use 600N / mm 2 Strength standard Welding strength test is carried out for each diamond segment, and the dry-type diamond grinding wheel after welding is removed with a sandblasting machine to remove the oxide ...

Embodiment 2

[0042]The raw materials of the diamond cutter head are: copper powder 2.7kg, iron 3.6kg, nickel 0.7kg, cobalt 1.6kg, tin 1.0kg and rare earth element 0.14kg, put into the mixing tank and mix for 30 minutes, add liquid paraffin 0.11kg and diamond (grain size 40 / 45 mesh, compressive strength 30kg) 0.15kg, continue mixing for 3 hours, pour the powder into the mold for cold pressing, hot pressing and sintering, grind the knife head with the grinding wheel, and connect the knife head with the silver solder Put them together on the corresponding substrate position according to the requirements of the drawings, adjust the welding position, heat and melt the silver solder, so that the cutter head and the substrate are welded together, and then use 600N / mm 2 Strength standard Welding strength test is carried out for each diamond segment, and the dry-type diamond grinding wheel after welding is removed with a sandblasting machine to remove the oxide scale on the substrate surface caused ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com