Method for preparing concave mirror on optical waveguide

A technology of concave mirror and optical waveguide, which is applied in the direction of optical waveguide, light guide, optics, etc., can solve the problems of large concave surface roughness and large reflection concave surface roughness, and achieve the effect of flexible operation, simple structure and improved plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

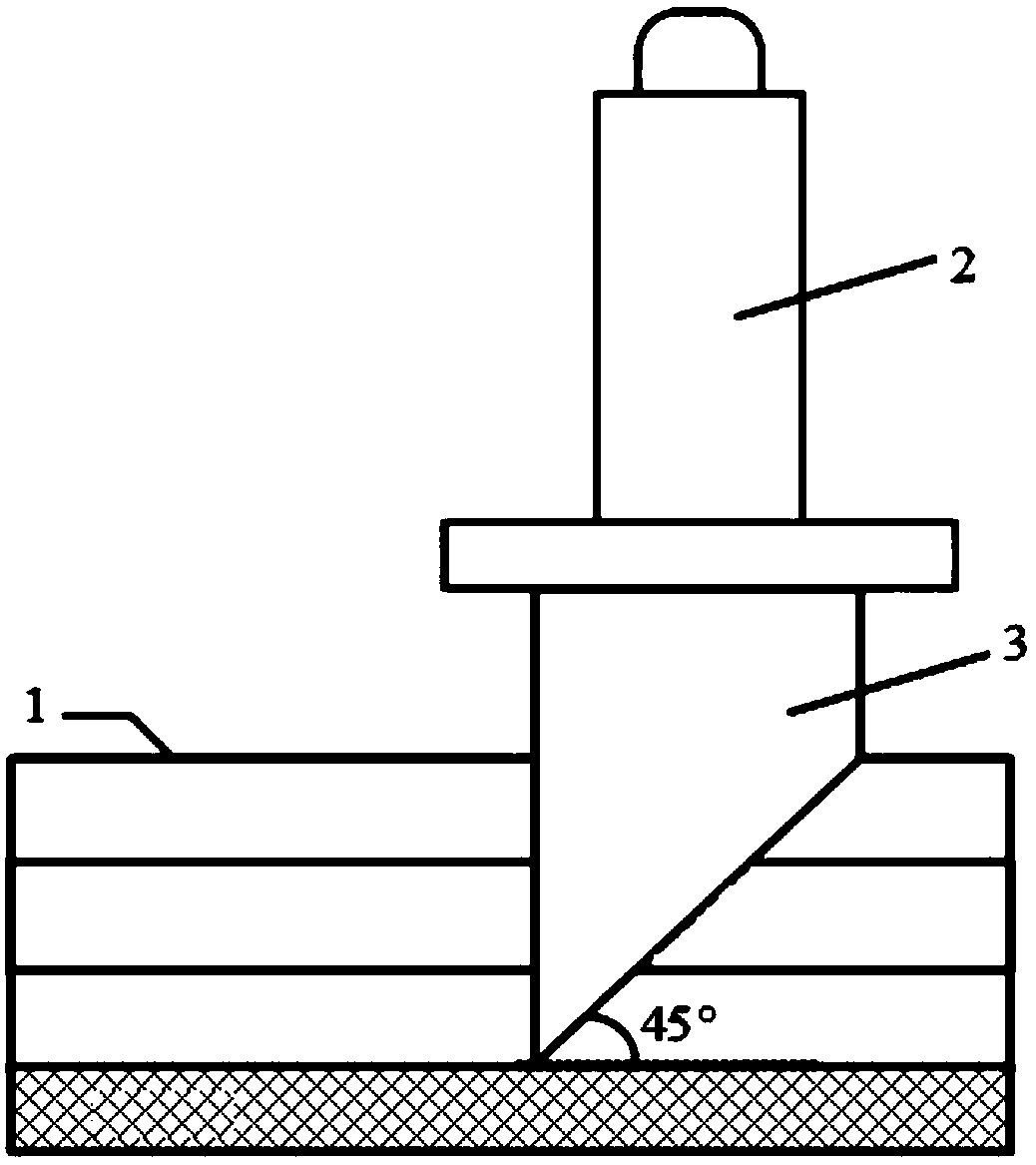

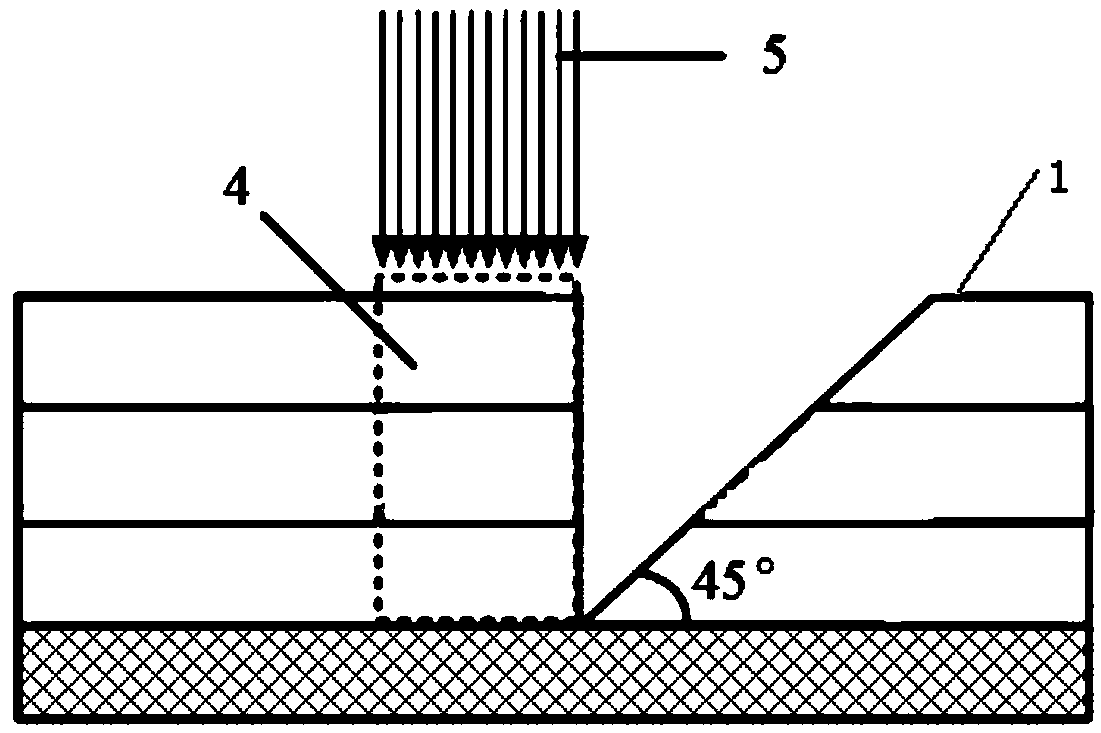

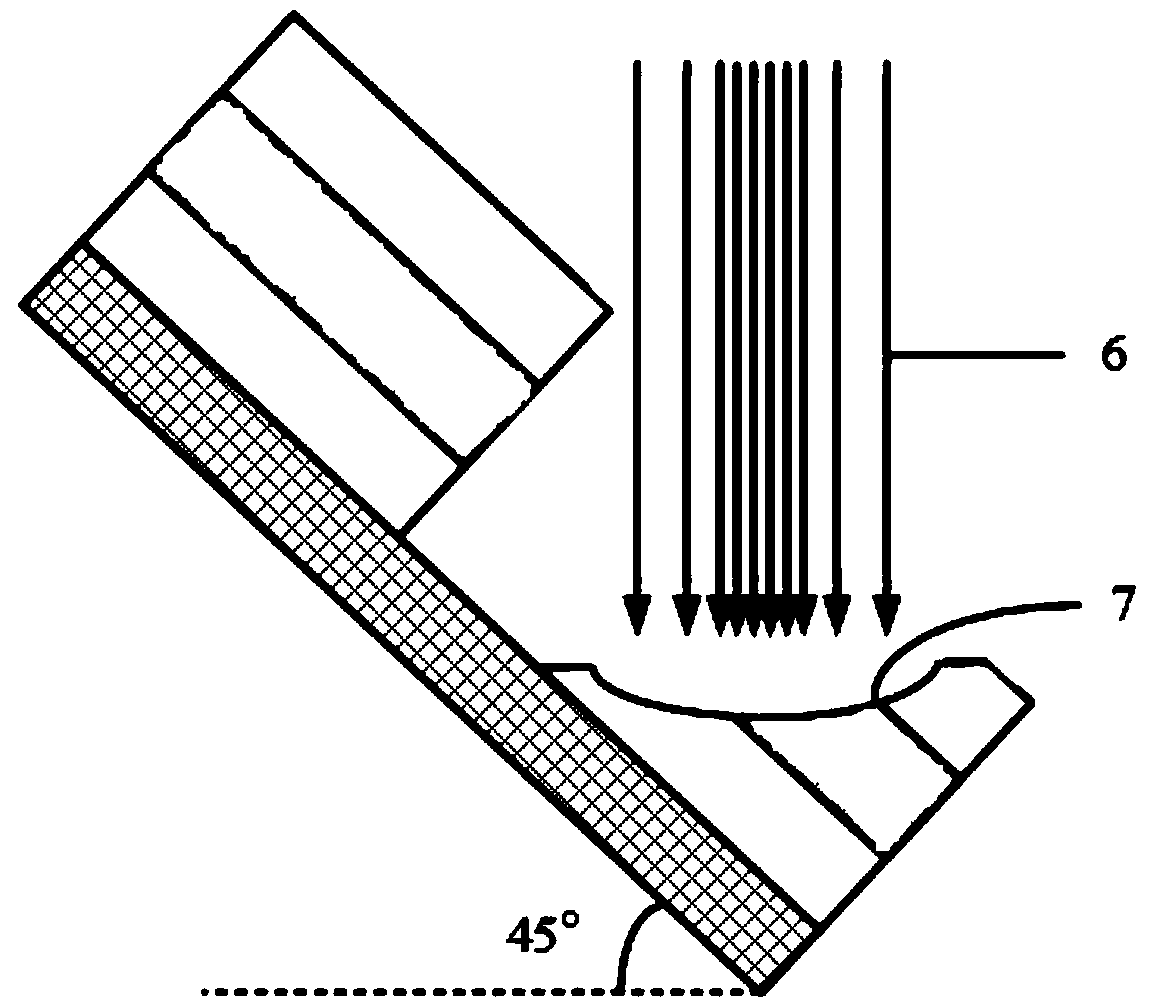

[0027] A method for preparing a concave mirror on a polymer optical waveguide, comprising the following steps: Step 1, using a V-shaped diamond knife to cut the optical waveguide into a V-shaped groove, one side of the V-shaped used is a 45° inclined surface, and one side is a vertical surface, Such as figure 1 As shown, the optical waveguide 1 includes four layers, which are the substrate, the lower cladding layer, the core layer and the upper cladding layer from bottom to top, and the v-shaped diamond cutter head can be cut to the lower cladding layer; step 2, using an excimer laser The vertical surface next to the v-shaped groove is one side, and the required laser energy is 5mJ to etch the cube groove. The width of the cube groove is 2 / 3-1 times the depth of the v-shaped groove, and the depth is the same as the depth of the v-shaped groove; step 3 , place the plate obliquely so that the inclined surface of the v-shaped groove is horizontal, and use a carbon dioxide laser t...

Embodiment 2

[0030] A method for preparing a concave mirror on an inorganic material (such as glass) optical waveguide, the preparation method is basically the same as that of Embodiment 1, but the laser processing parameters need to be changed. When the excimer laser etches the cube groove in step 2, the required laser energy is above 7mJ. In step 3, when the carbon dioxide laser thermally ablates the inclined surface of the V-shaped groove into a concave surface, the laser pulse energy needs to be increased to 102W, and after the inclined surface is ablated into a concave surface, it is etched with FH acid. The specific FH acid concentration and corrosion Time has a certain effect on the radius and roughness of the concave surface. Then proceed to step 4, that is, to coat the concave surface with a high reflection film to form a concave mirror.

[0031] The above specific parameter settings are only a specific example of a certain inorganic material optical waveguide, and are not limite...

Embodiment 3

[0033]Embodiment 1 and Embodiment 2 are specific instructions for etching concave surfaces of optical waveguides made of different materials. Compared with existing concave surface preparation technologies (publication numbers: CN 1272182A, CN 103395739A, paper: Design and fabrication of embedded micro-mirror inserts for out -of-plane coupling in PCB leveloptical interconnections), the present invention overcomes the deficiencies and problems in terms of materials, preparation technology, processing precision, etc., and meets the requirements of large-scale industrial production of optical backplanes. The technical invention (application number 201710076388.7) is a form of cold processing, which requires suitable mask patterns, precise parameter settings and operations. The reflective concave surface processed by this method has a relatively large roughness and requires subsequent thermal annealing process. The present invention The research group proposed to use a carbon dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Laser wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com