Diamond tool bit, preparation method of diamond tool bit, cold pressing mold for diamond tool bit, and diamond saw blade

A technology of diamond cutter head and cold pressing mold, which is applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of low overall quality of laser-welded diamond saw blade products, reduced welding strength, and high rejection rate. Reduce production cost, save the process of cutting edge, the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

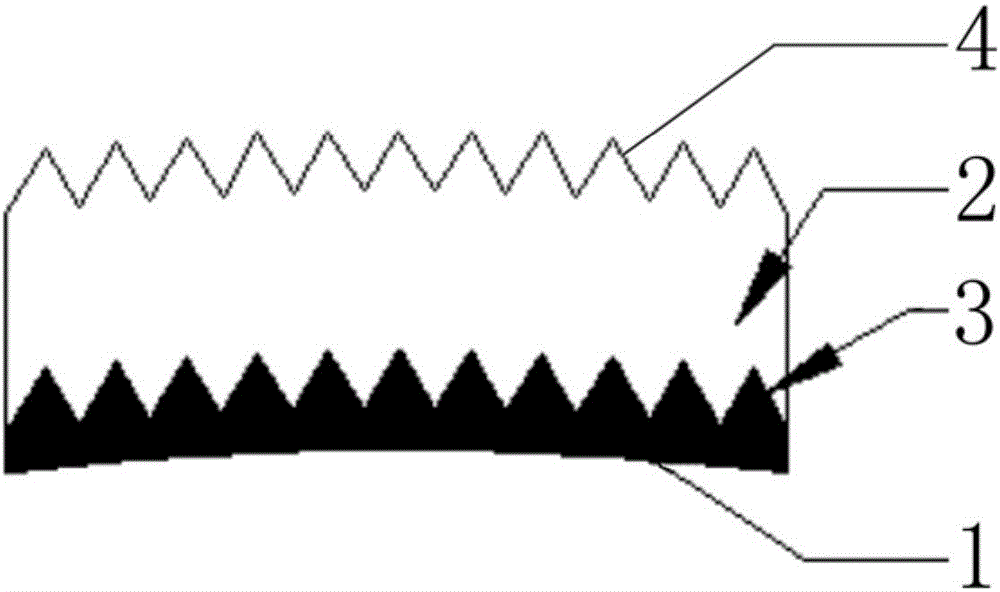

[0061] The serrated diamond bit of the present embodiment, as figure 1 As shown, it includes a diamond-free transition layer 1 and a diamond-containing working layer 2, and the junction 3 between the transition layer 1 and the working layer 2 is a sawtooth structure; meanwhile, the working surface 4 of the working layer 2 is also sawtooth structure. The protrusions and recesses of the sawtooth structure have side walls that stop and fit in the circumferential direction of the cutter head. The welding surface of the transition layer 1 used for welding with the substrate is a curved surface concave toward the cutter head.

Embodiment 2

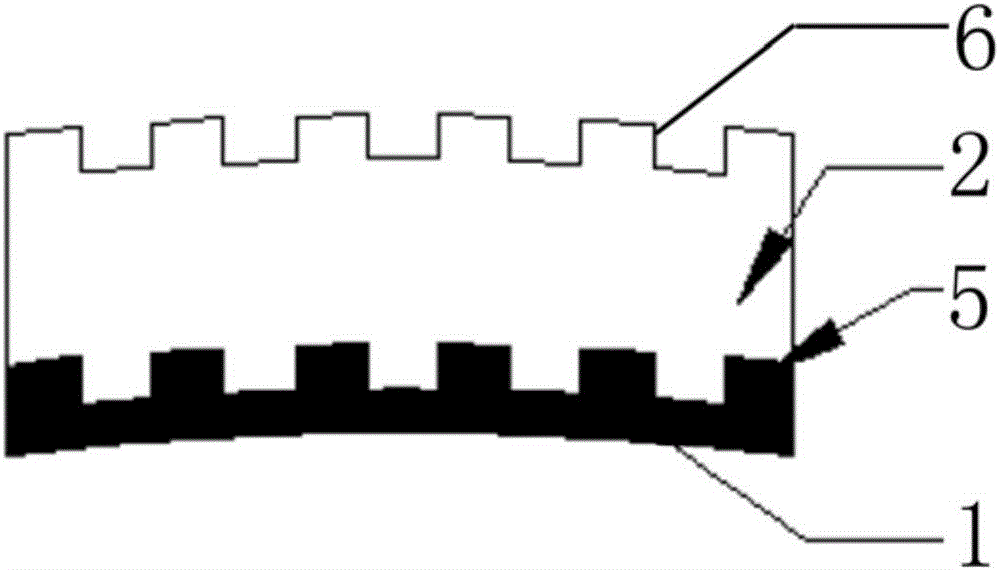

[0063] The square-wave diamond cutter bit of the present embodiment, as figure 2 As shown, it includes a transition layer 1 without diamond and a working layer 2 containing diamond. It is a square wave structure. The protrusions and depressions of the above-mentioned square wave structure have side walls that stop and fit in the circumferential direction of the cutter head. The welding surface of the transition layer 1 used for welding with the substrate is a curved surface concave toward the cutter head.

Embodiment 3

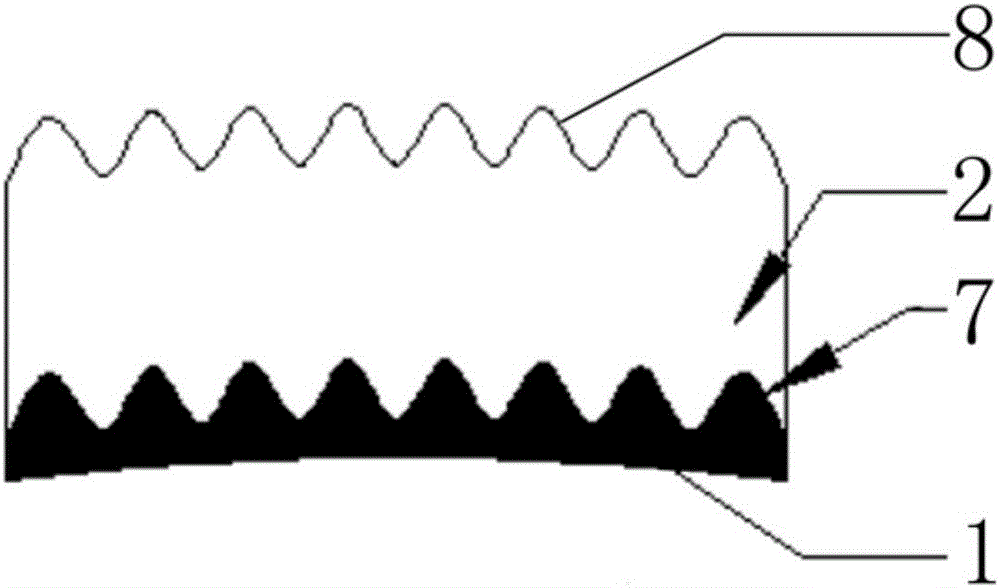

[0065] The wavy diamond cutter head of the present embodiment, as image 3 As shown, it includes a diamond-free transition layer 1 and a diamond-containing working layer 2, and the joint 7 between the transition layer 1 and the working layer 2 is a wave structure; meanwhile, the working surface 8 of the working layer 2 is also Wavy structure. The above-mentioned protrusions and depressions of the corrugated structure have side walls that stop and fit in the circumferential direction of the cutter head. The welding surface of the transition layer 1 used for welding with the substrate is a curved surface concave toward the cutter head.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com