In-place detection and positioning device for diamond cutting tool

A technology of diamond tools and positioning devices, applied in automatic control devices, precision positioning equipment, manufacturing tools, etc., can solve the problems of in-situ detection, inability to work parameters of tools, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

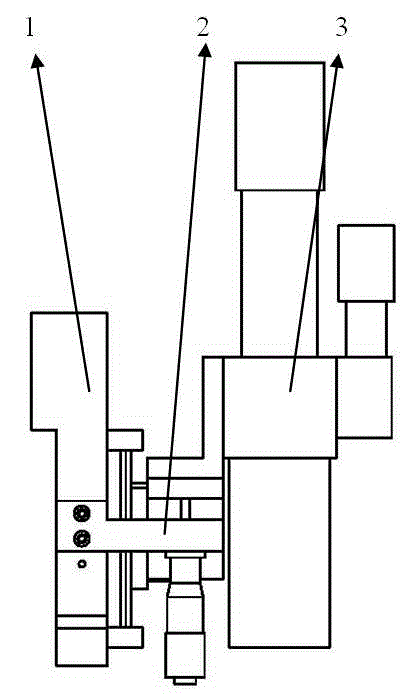

[0018] This example is figure 1 , figure 2 and image 3 shown.

[0019] The diamond cutter in-position detection and positioning device provided by the present invention includes an optical support 1, a fine-tuning and locking mechanism 2, an optical system 3, and an industrial computer. The fine-tuning and locking mechanism 2 is fixedly installed on the optical support 1, and the optical The system 1 is fixedly installed on the adapter plate 24 of the fine adjustment and locking mechanism 2, and moves up and down along the slide rail 23, such as figure 1 shown.

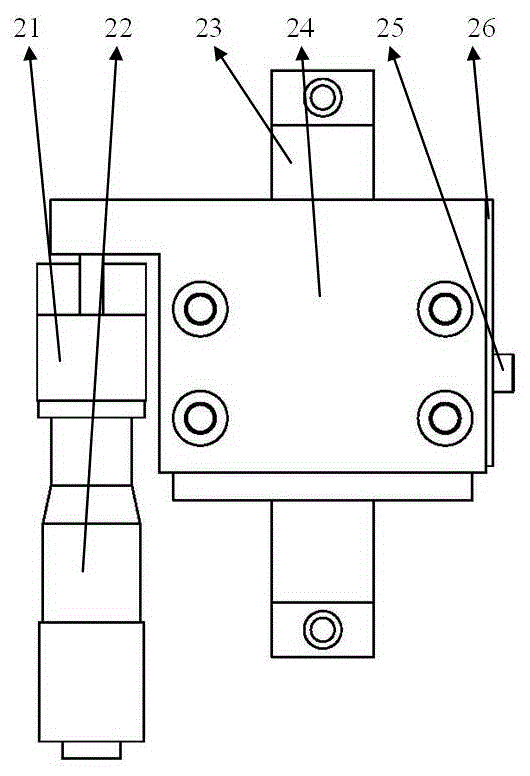

[0020] Described fine-tuning and locking mechanism 2 comprises screw rod fixed frame 21, fine-tuning screw rod 22, slide rail 23, adapter plate 24, locking screw 25, locking piece 26, and its connection relation is, screw rod fixed frame 21, slide rail 23. The locking pieces 26 are all fixedly connected with the optical bracket 1, the optical system 3 is installed on the adapter plate 24 of the fine-tuning and l...

Embodiment 2

[0024] This example is figure 1 shown.

[0025] The in-situ detection and positioning device of the diamond tool as described in Example 1 realizes the in-position detection and positioning of the diamond tool according to the following operation process: 1) The diamond tool is fixedly installed on the tool holder of the ultra-precision machine tool; 2) LVDT electric sensing is used The micrometer adjusts the diamond tool to the calibration position; 3) Move the X and Z guide rails of the ultra-precision lathe, place the diamond tool within the imaging range of the optical system 3, rotate the fine-tuning screw 22 to move the optical system 3 in the vertical direction, and adjust the reflection at the same time Brightness of the light source 32, until a clear image is obtained in the host computer software, tighten the locking screw 25; 5) Move the X guide rail of the ultra-precision machine tool to make the diamond tool move along a straight line within the imaging range, and...

Embodiment 3

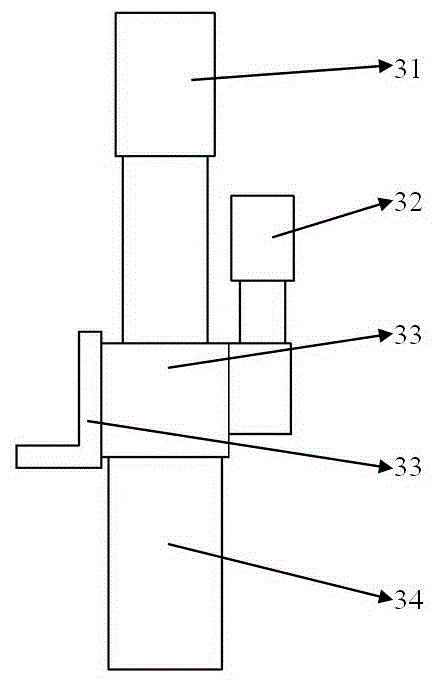

[0027] This example is image 3 shown.

[0028]As in the diamond tool in-position detection and positioning device described in Example 1, the optical system 3 adopts a 5 million-pixel CCD sensor 31, and the lens 34 is a fixed-focus lens with three magnifications of 10 times, 15 times and 20 times, and the reflection light source 32 is a blue LED cold light source, the imaging resolution of the optical system 3 is less than 0.5mm, and the highest resolution can reach 0.16mm according to the different multiples of the lens 34 .

[0029] The diamond cutter in-position detection and positioning device is used to locate the diamond cutter on an ultra-precision machine tool, and the positioning accuracy is better than 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com