Automatic die dismantling and mounting method suitable for diamond knife head die

A diamond cutter head and mold technology, which is applied in chemical instruments and methods, manufacturing tools, solid separation, etc., can solve the problems of easily stabbing employees' fingers, many burrs in cold-pressed blanks, and high labor intensity, and achieves convenient screening operations and automation. High level, continuous action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be described below with reference to the drawings.

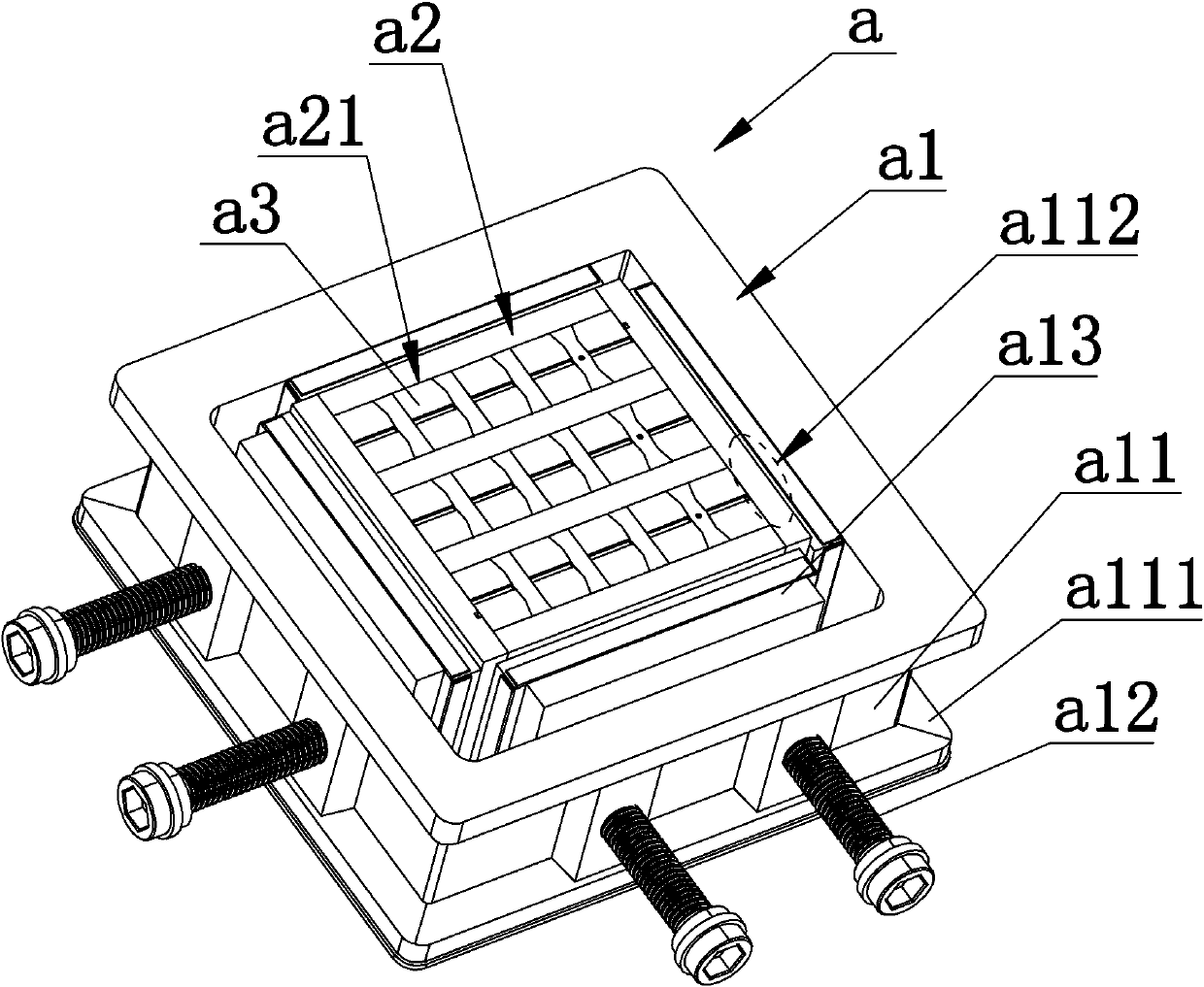

[0037] Reference figure 1 with image 3 , In order to facilitate understanding, first introduce the specific structure of the diamond tool bit mold a. The diamond tool bit mold a mainly includes a mold frame a1, a mold main body a2, and several pressing blocks a3. The mold frame a1 is composed of a frame a11 and two clamping plates a13 adjustable and set inside the frame a11 through a locking screw a12. The mold main body a2 is clamped between the two clamping plates a13 and the frame a11 by adjusting the locking screw a12. The main body of the mold is provided with a plurality of forming holes a21, each forming hole a21 is provided with a number of compacts a3 at intervals, and between two adjacent compacts a3 are cold compacts molded from metal raw materials. These cold compacts After sintering, the diamond bits are formed one by one. In order to better fix the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com