Diamond tool bit positioning seat and welding machine for diamond cutting tool

A diamond cutter head and diamond cutting technology, applied in metal processing, manufacturing tools, welding equipment, etc., can solve the problems of lack of versatility, high equipment manufacturing and maintenance costs, error-prone, etc., to achieve convenient and easy adjustment, and ensure consistency High performance and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

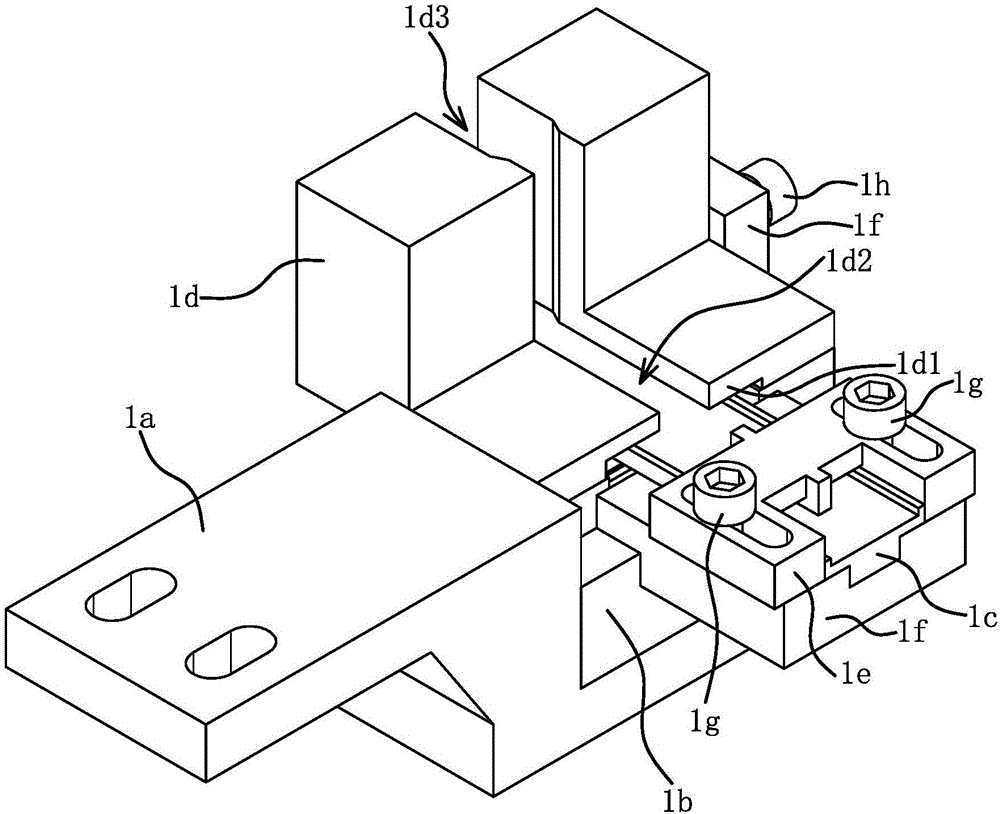

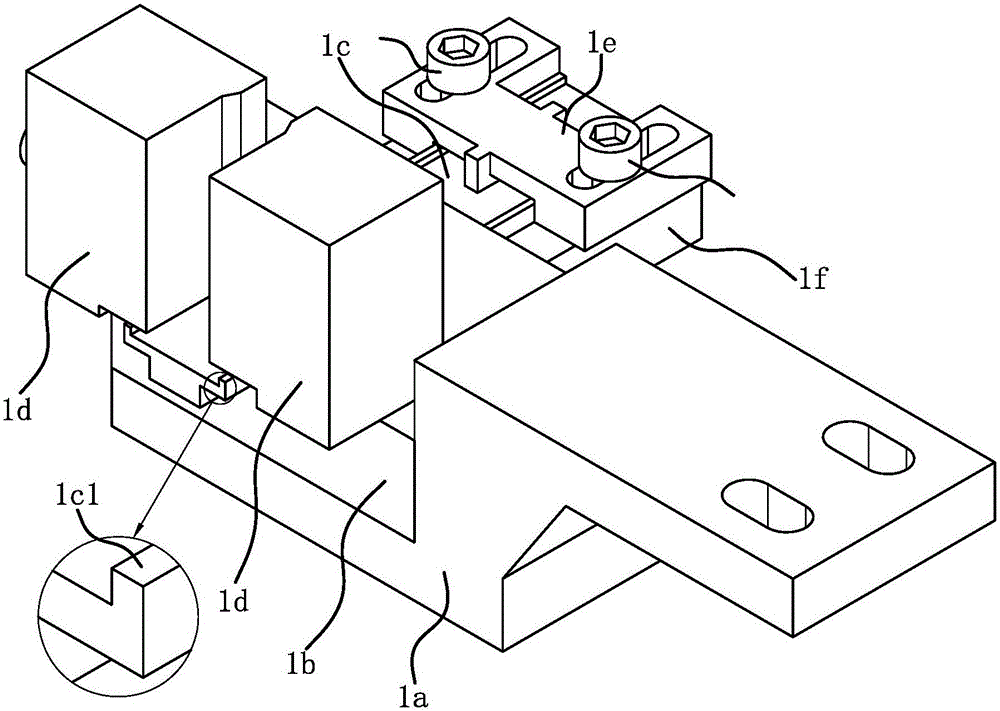

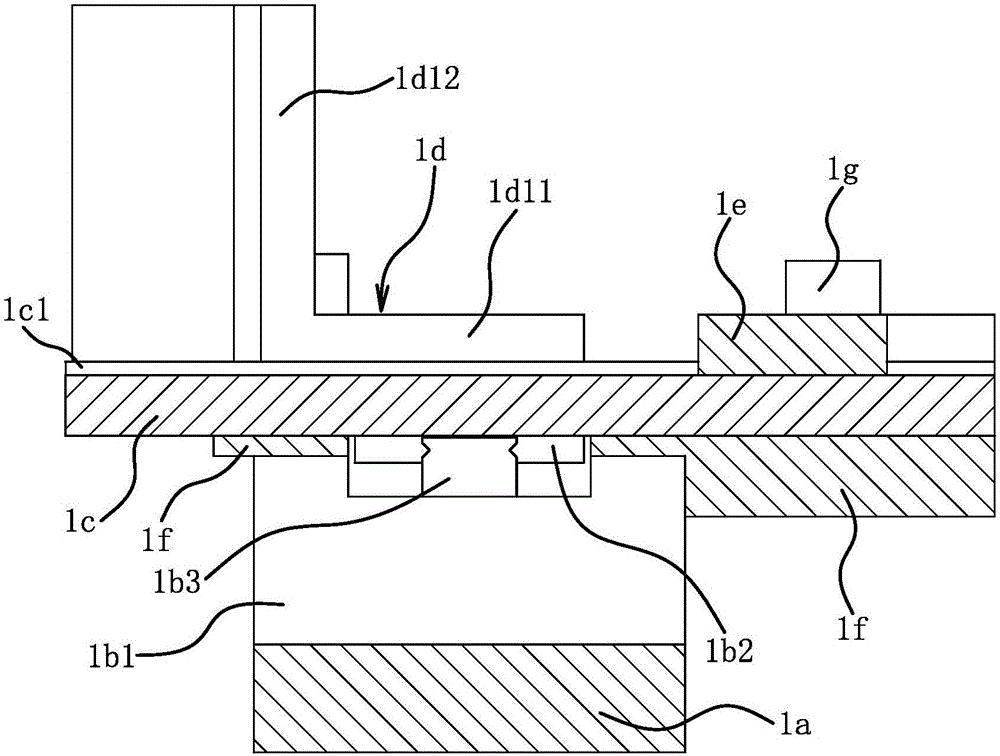

[0021] like Figure 1 to Figure 3 As shown, the diamond cutter head positioning seat 1 includes a base 1a, a synchronous pneumatic clamp 1b, a cutter head holding plate 1c, a chuck 1d and a cutter head end surface support 1e.

[0022] The base 1a is a base member. The synchronous pneumatic clamp 1b includes a cylinder body 1b1, two slide heads 1b2 and a first guide rail 1b3, the two slide heads 1b2 are connected with the cylinder body 1b1 through the above-mentioned set of first guide rails 1b3, and the two slide heads 1b2 can move toward or back , that is, the two sliders 1b2 approach when they move toward each other, and the two sliders 1b2 move away from each other when they move in the opposite direction.

[0023] The cutter head supporting plate 1c is strip-shaped; the synchronous pneumatic clamp 1b is located under the cutter head supporting plate 1c, the cylinder 1b1 of the synchronous pneumatic clamp 1b is fixedly connected to the base 1a, and the first guide rail 1b3...

Embodiment 2

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described repeatedly, and only the differences will be described. The difference is that the diamond cutter head positioning seat 1 is located If it is directly ahead, then the guiding direction of the second guide rail 6 is perpendicular to the clamping surface of the saw blade base clamping tool.

Embodiment 3

[0038] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly. Only the differences will be described. The difference is that the mechanical moving device is a flexible manipulator, and the flexible manipulator includes a base and a mounting head. , the base is fixedly connected to the frame 2, and the base 1a of the diamond bit positioning seat 1 is fixedly connected to the installation head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com