Preparation method of complex CVD (chemical vapor deposition) diamond cutter

A diamond tool and diamond thick film technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of difficult processing of CVD diamond tools, low processing efficiency, high processing cost, and the probability of cracking The effect of lowering, high mold utilization rate, and lowering production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

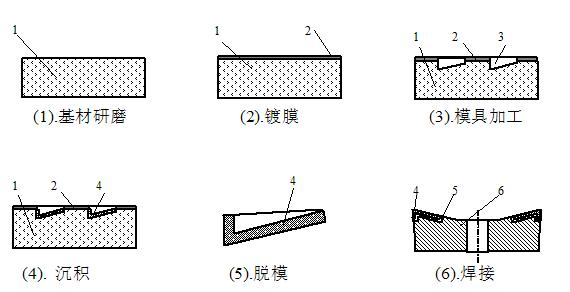

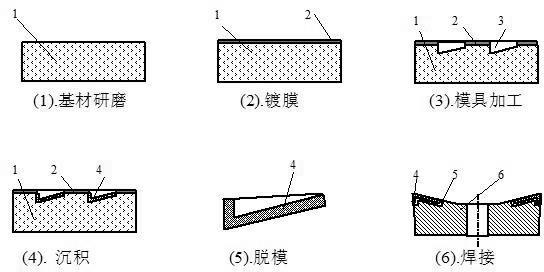

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] like figure 1 shown.

[0031] A preparation method of a complex CVD diamond thick film cutter, which comprises the following steps:

[0032] Substrate preparation: choose materials that are easy to process and suitable for diamond deposition and growth, such as Si or Mo, as the substrate 1, and control the thickness of the substrate t≥5mm. Both sides of the substrate are ground first, and then deposited on one of the surfaces with a thickness greater than 5 μm Co and Al are materials whose melting point is higher than 1500°C and diamond is not easy to nucleate and grow 2 o 3 Or one of Fe is used as the barrier film 2, and the deposition method of the barrier film 2 can be sputtering, ion plating, chemical vapor deposition, etc.;

[0033] Mold processing: On the side of the substrate 1 with the barrier film 2, a concave mold cavity 3 consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com