a ti 2 Alnb-based alloy material and preparation method thereof

A technology of base alloy and composite material, applied in the field of Ti2AlNb base alloy material and its preparation, can solve the problems of complex preparation method and high cost of AlNb base alloy, and achieve the effects of performance optimization, avoidance of forming processing and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

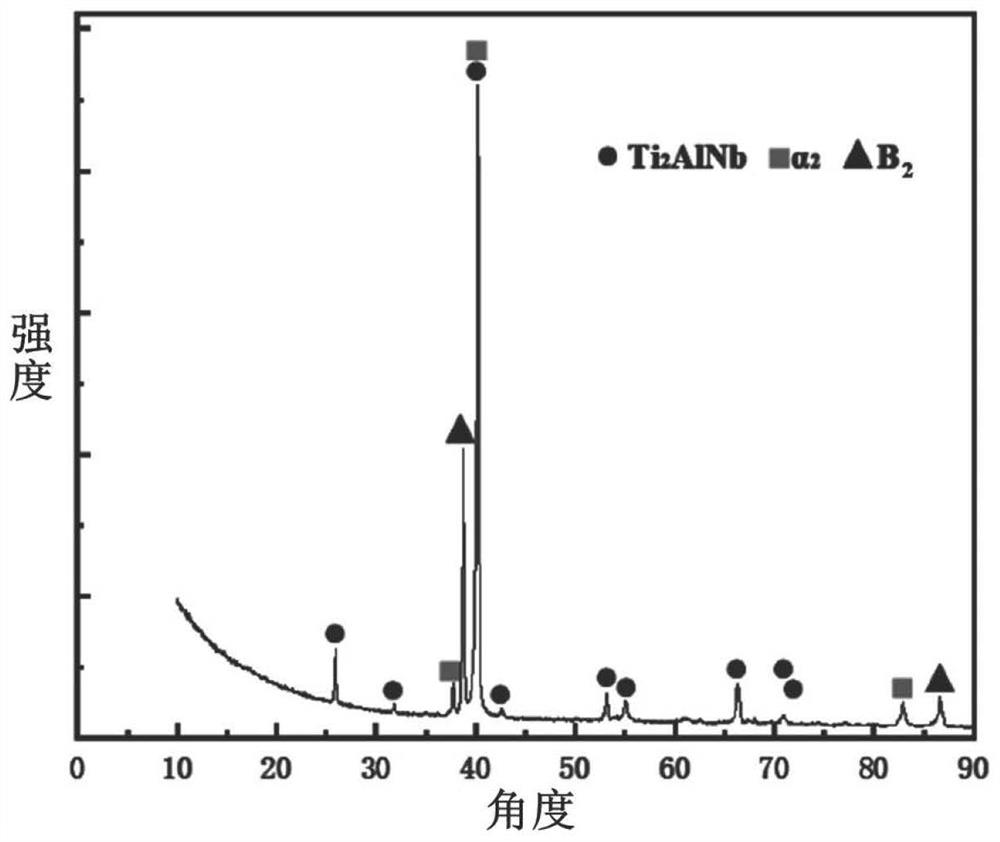

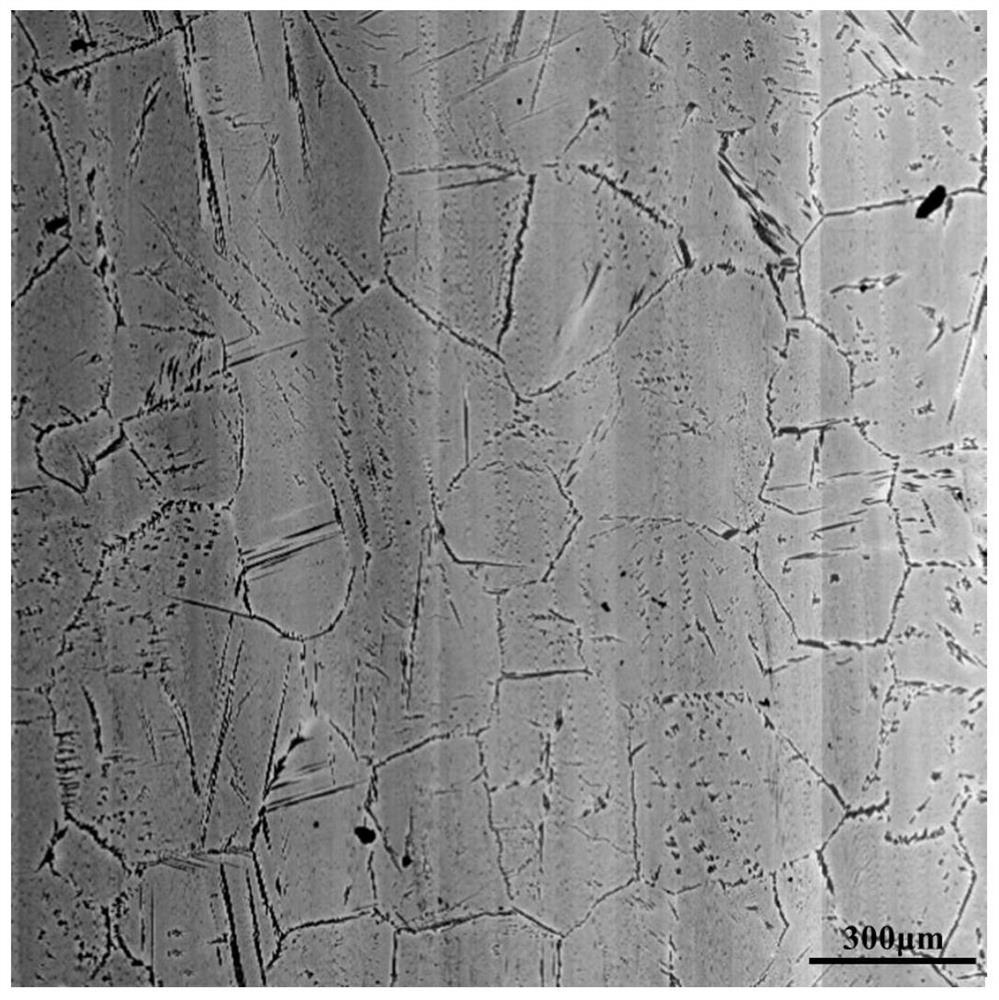

[0021] Specific implementation mode 1: what is described in this implementation mode is a kind of Ti 2 AlNb-based alloy materials, the Ti 2 AlNb-based alloy materials include O phase (Ti 2 AlNb phase) Ti 2 AlNb-based alloys; also includes α 2 Phase (Ti 3 One or both of Al phase) and β phase (B2 phase); the organization can be one of equiaxed organization, double state organization or lamellar organization.

specific Embodiment approach 2

[0022] Specific embodiment two: a kind of Ti described in specific embodiment one 2 A method for preparing an AlNb-based alloy material, the method steps are as follows:

[0023] 1. Use alcohol and acetone to ultrasonically clean Ti foil, Al foil and Nb foil respectively (2000W) for 5 to 10 minutes to remove surface oil, and then use 5vol.% to 15vol.% HF, 40vol.% HF and 5% vol .~15vol.% NaOH solution to clean the surface of Ti foil, Nb foil and Al foil respectively to remove the surface scale, and finally clean it with alcohol ultrasonic (2000W) for 2~5min, then dry it with a hair dryer for later use;

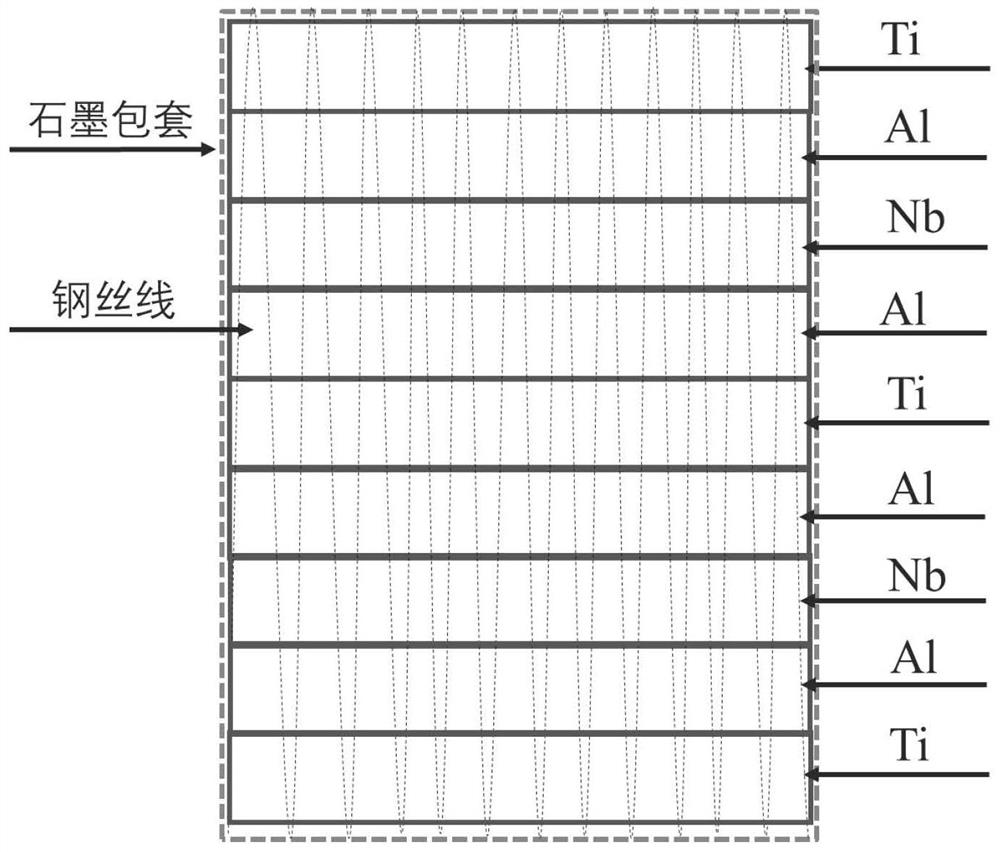

[0024] 2. Ti foil, Nb foil and Al foil, which have been surface treated in step one, are subjected to Ti 2 The lamination of AlNb-based alloys, specifically: ensure that the number of Ti foils is an odd number, and the number of Al foils and Nb foils is an even number, according to a periodic layer of Ti-Al-Nb-Al-Ti-Al-Nb-Al-Ti structure. Lamination; then wrap with graphite p...

Embodiment 1

[0035] 1. Use alcohol and acetone to ultrasonically clean the Ti foil, Al foil and Nb foil for 5 minutes respectively to remove the oil on the surface, and then use 10vol.% HF, 100vol.% HF and 10vol.% NaOH solutions to clean the Ti foil and Nb foil respectively Clean the surface with Al foil to remove the oxide skin on the surface, and finally clean it with alcohol ultrasonic (2000W) for 5 minutes, then dry it with a hair dryer for later use;

[0036] 2. The Ti foil, Nb foil and Al foil that have been surface-treated in step 1 are treated according to the atomic percentage of Ti-22Al-25Nb. 2 Lamination of AlNb-based alloy, then wrapping with graphite paper, and finally fixing the lamination with a steel wire with a thickness of 0.15 mm to prepare Ti 2 AlNb-based alloy preforms;

[0037] Three, the Ti prepared in step 2 2 AlNb-based alloy preforms were loaded into graphite molds, then placed in a vacuum hot-press furnace, and vacuumed to 1×10 -3 Below Pa, hot press at 550°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com