Method for rapidly preparing gradient titanium plate based on vacuum hot pressing process

A vacuum hot pressing and gradient technology, which is applied in the field of non-ferrous metal plastic forming, can solve the problems of complex process flow and thin gradient layer, and achieve the effect of avoiding forming processing and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The preparation method of the gradient titanium plate in this embodiment specifically comprises the following steps:

[0031] Step 1, first prepare titanium foils with thicknesses of 10 μm, 20 μm, 50 μm, and 100 μm, then use alcohol to ultrasonically clean the titanium foils for 5 minutes to 10 minutes, then use 10vol% HF solution to clean the surface of the Ti foils to remove surface oxide skin, and finally After ultrasonic cleaning with alcohol for 2 to 5 minutes, dry it and put it in a dust-free box for later use;

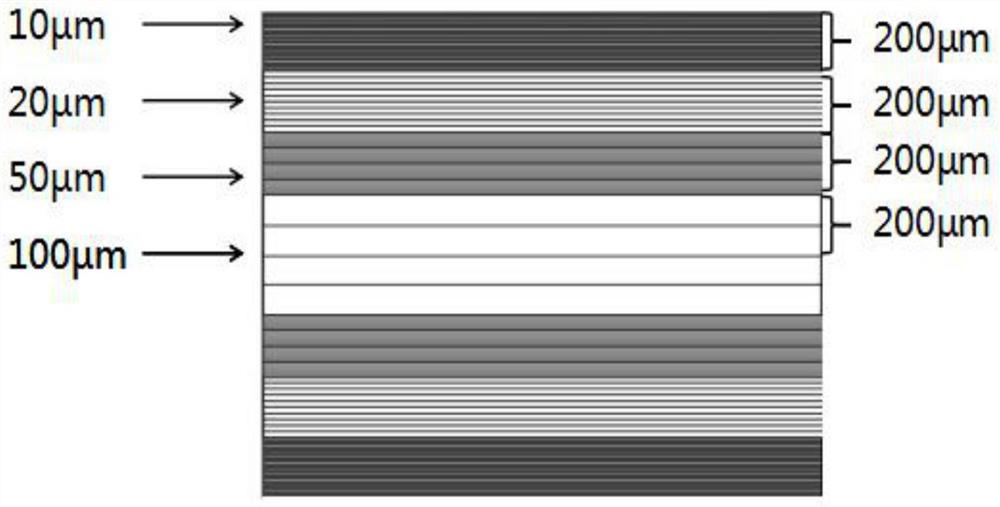

[0032] Step 2, use the washed titanium foil to design the gradient structure. The number of layers of titanium foil laminates of each thickness is different, but the thickness of the laminates of different thickness titanium foils is the same, and the thickness is stacked from thin to thick and then to thin. layers, see the laminated structure figure 1 , the total thickness of the gradient titanium plate after stacking is 1.6mm;

[0033] S...

Embodiment 2

[0036] Embodiment 2: The preparation method of the gradient titanium plate in this embodiment specifically comprises the following steps:

[0037] Step 1, first prepare titanium foils with thicknesses of 20 μm, 50 μm, and 100 μm, then use alcohol to ultrasonically clean the titanium foil for 10 minutes, then use 10vol% HF solution to clean the surface of the Ti foil to remove surface oxide skin, and finally use alcohol to ultrasonically clean After 5 minutes, dry it and put it in a dust-free box for later use;

[0038] Step 2, use the washed titanium foil to design the gradient structure. The number of layers of titanium foil laminates of each thickness is different, but the thickness of the laminates of different thickness titanium foils is the same, and the thickness is stacked from thin to thick and then to thin. layers, see the laminated structure figure 1 , the total thickness of the gradient titanium plate after stacking is 1.2mm;

[0039] Step 3, using a steel wire ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com