A kind of nb-tial layered composite material and preparation method thereof

A layered composite material and composite material technology are applied in the field of Nb-TiAl layered composite material and its preparation, which can solve the problems of near-formed preparation of sheet shape and complexity, and achieve the effect of avoiding forming processing and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

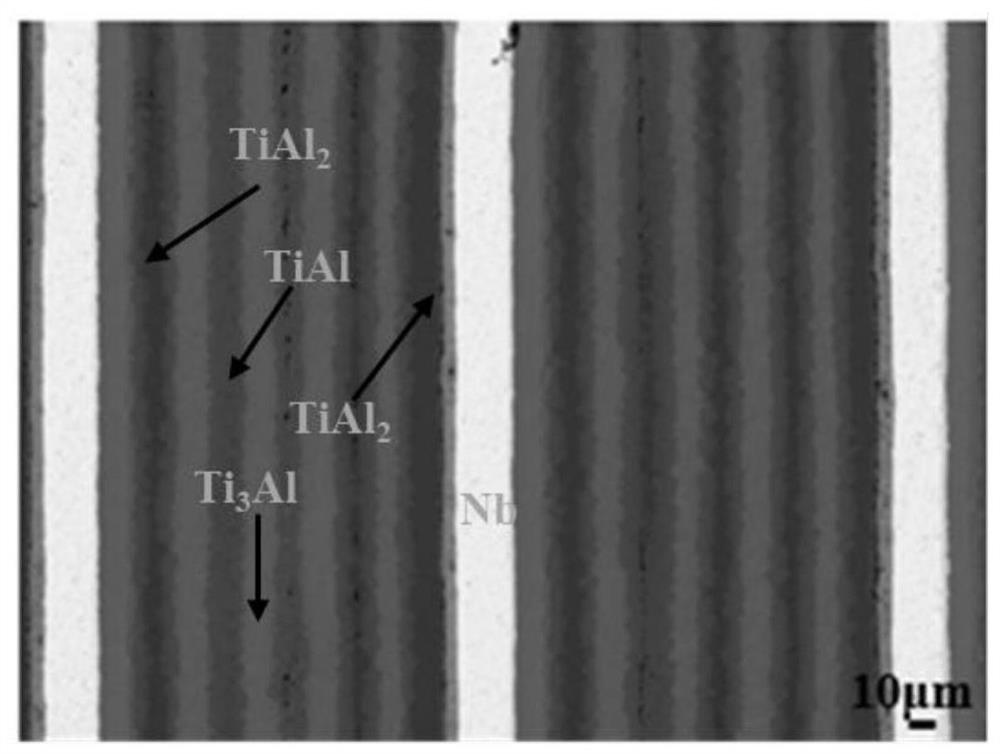

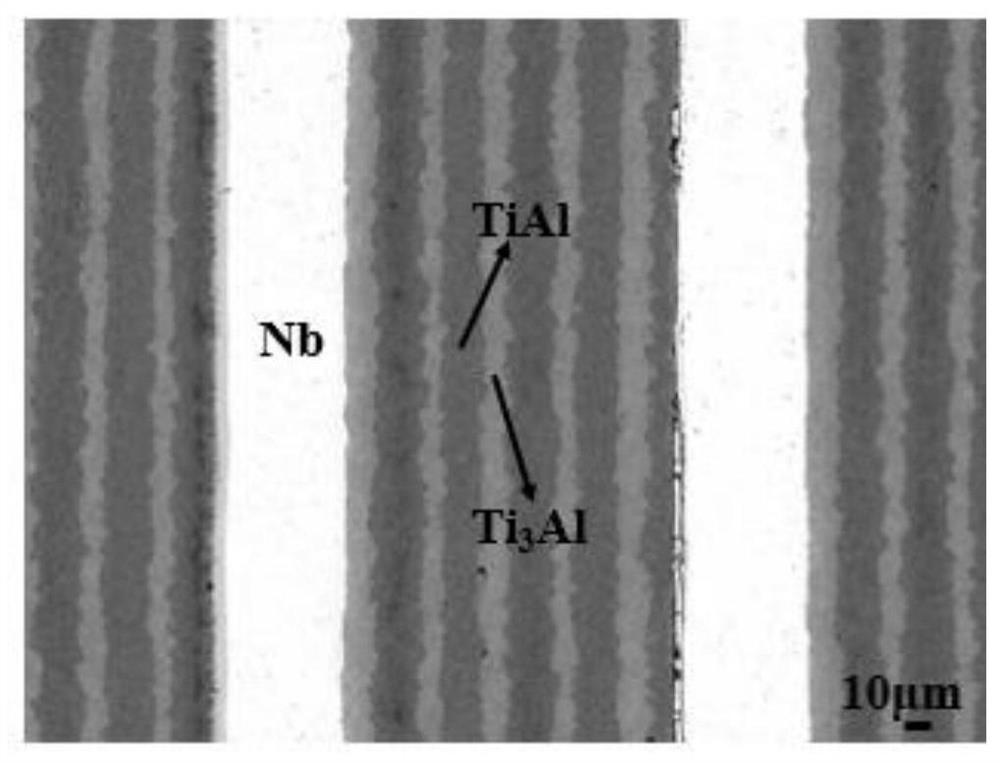

[0020] Specific embodiment 1: This embodiment describes a kind of Nb-TiAl layered composite material, and the described Nb-TiAl layered composite material is made of periodic Nb / Ti 3 Al-TiAl / Nb structure composition, Nb is pure Nb, between the upper and lower pure Nb layers, alternately set Ti 3 Al layer and TiAl layer, and constitute a periodic stacked structure.

[0021] Specific embodiment 2: A kind of Nb-TiAl layered composite material described in specific embodiment 1, the thickness of the single layer of pure Nb layer is 20~50 μm, it is mainly used as the toughness layer of the composite material, and has good High temperature resistance.

[0022] Specific embodiment three: a kind of Nb-TiAl layered composite material described in specific embodiment one, the Ti 3 The thickness ratio of the Al layer to the TiAl layer is 1:1~2, which can be adjusted by adjusting the thickness ratio of the raw materials Ti foil and Al foil during the preparation process or by controllin...

specific Embodiment approach 5

[0024] Embodiment 5: A method for preparing the Nb-TiAl layered composite material described in any of Embodiments 1 to 4, the method is carried out according to the following steps:

[0025] Step 1: Use alcohol and acetone to ultrasonically clean Ti foil, Al foil and Nb foil respectively (power 2000W) for 5 to 10 minutes to remove surface oil, and then use 5vol.% to 15vol.% HF, 100vol.% HF and 5vol .% ~ 15vol.% NaOH solution to clean the surface of Ti foil, Nb foil and Al foil respectively to remove the scale on the surface, and finally use alcohol ultrasonic (power 2000W) to clean for 2 ~ 5min, then dry it with a hair dryer for later use;

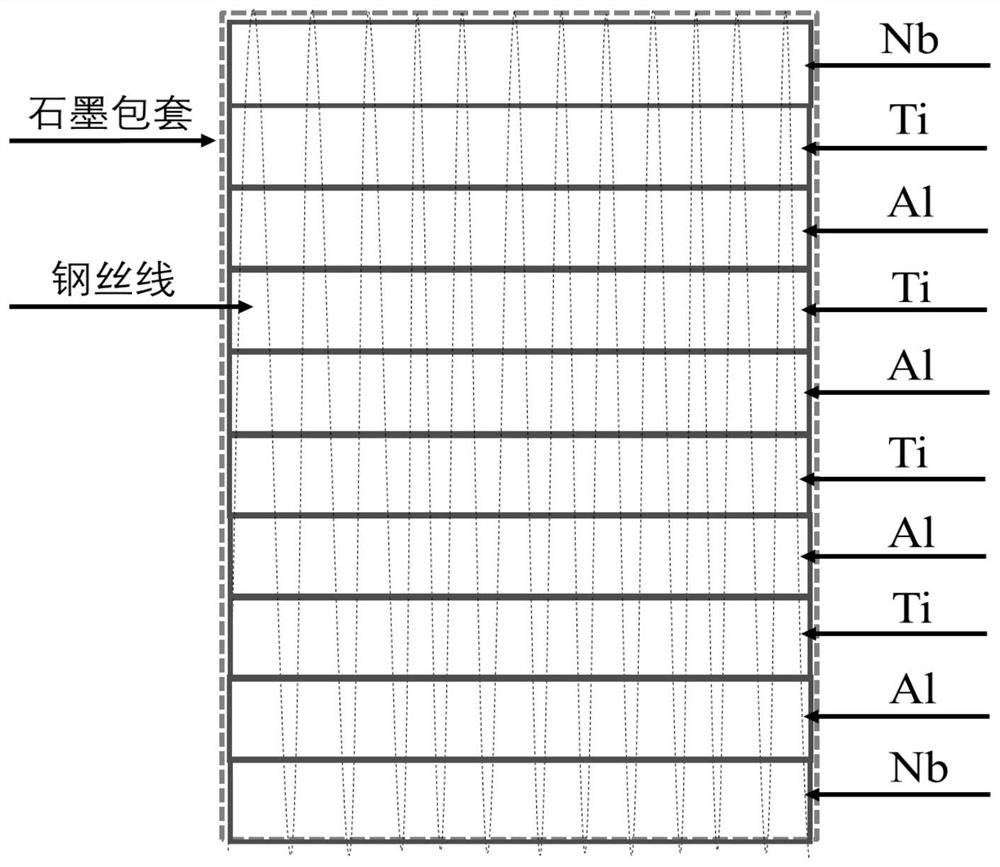

[0026] Step 2: Laminate the Ti foil, Al foil and Nb foil washed in step 1. In order to ensure that the cross-section of all foils is the same during sample loading and hot pressing, wrap the stacked materials with graphite paper , and use a steel wire with a diameter of 0.1 to 0.2mm to fix the stack to obtain a Nb / high Nb-TiAl layered com...

Embodiment 1

[0039] 1. First use alcohol and acetone to ultrasonically clean Ti foil, Al foil and Nb foil respectively for 5 minutes to remove surface oil, and then use 10vol.% HF, 100vol.% HF and 10vol.% NaOH solutions to clean Ti foil, Nb foil and Al foil to clean the surface to remove the scale on the surface, and finally use alcohol to ultrasonically clean it for 5 minutes, then dry it with a hair dryer for later use; the thickness of the Ti foil is 20 μm, the thickness of the Al foil is 17 μm, and the thickness of the Nb foil The thickness is 25μm;

[0040] 2. Stack the Ti foil, Al foil and Nb foil washed in step 1. The stacking sequence is that the Nb foil is at the top and bottom of a cycle of stacking, and the middle layer is alternate Ti foil and Al foil; In order to ensure that all foil materials are always in one plane during sample loading and hot pressing, the stacked materials are coated with graphite, and the stack is fixed with a steel wire with a diameter of 0.15mm to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com