Method for preparing rare earth fluorescence micro/nano fibers

A technology of micro-nano fiber and rare earth fluorescence, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textile and paper making, etc. It can solve the problems of high content of luminescent materials, poor strength and processing performance, and difficulty in development and application. Avoid the effects of poor environmental stability, easy molding, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

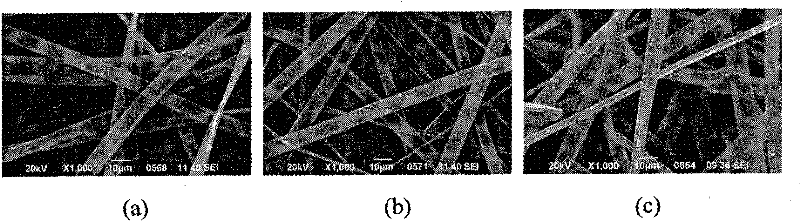

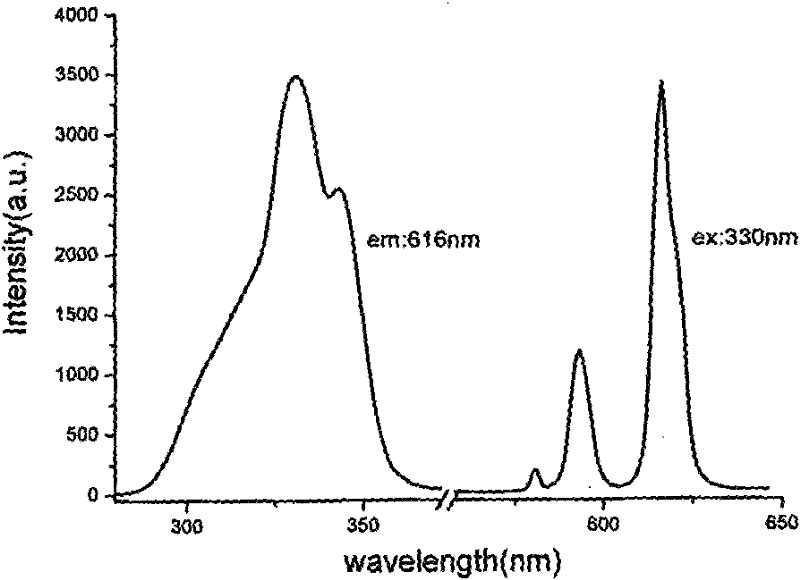

[0014] Weigh 0.352 grams of Eu 2 O 3 (1 mmol) + 12 ml HCl (excess) to produce EuCl 3 , And dry it to make the hydrochloric acid completely volatilize, the EuCl 3 Dissolve 1.081 g of acetylsalicylic acid in 50 g of absolute ethanol, add an excess of 1.5 g of triethylamine and filter, slowly add 0.404 g of o-phenol Rowling ethanol solution, keep stirring, leave it for 2 hours and filter with suction, then use 50 Wash in gram of absolute ethanol for 1 hour, filter with suction, and dry to obtain a white powdered rare earth complex; then dissolve 0.05 g of rare earth complex in 1.45 g of chloroform, stir and add 2 g of 25% polyphenylene by mass The ethylene tetrahydrofuran solution is stirred evenly to prepare a precursor solution for electrospinning; it is spun in the air by a conventional electrospinning method, the spinning conditions are: voltage 20 kV, inner diameter of the nozzle is 0.42 mm, The distance between the nozzle and the collector is 15 cm, the temperature is 20°C, t...

Embodiment 2

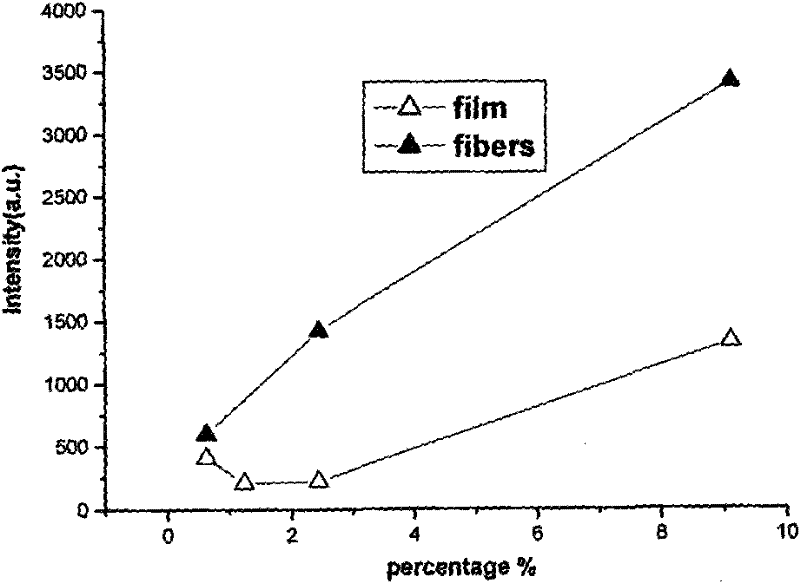

[0016] According to the method of Example 1, 4 grams of precursor solutions with different mass ratios (rare earth complex: polymer material: 1:160, 1:80, 1:40, 1:10) were prepared, respectively, and each The solution was divided into two parts, one part was subjected to electrospinning to collect fibers according to the conditions of Example 1, and the other part was dropped on a transparent glass plate and dried in air to prepare a thin film with a thickness of about 200 microns; by a fluorescence spectrophotometer (Hitachi F- 4600) The fluorescence spectra of the prepared fibers and films with different mass ratios were scanned; the results showed that the fluorescence intensity of the micro-nano fiber samples increased linearly with the increase of the complex concentration, and the bulk film samples in the rare earth complexes: high When the molecular material is about 1:100, the fluorescence quenching phenomenon appears, such as image 3 As shown; this is because the rare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com