A kind of nb/high nb-tial layered composite material and preparation method thereof

A layered composite material and alloy technology, which is applied in the direction of layered product processing, metal layered products, chemical instruments and methods, etc., can solve the problems of high cost, difficult processing and forming, and difficult to prepare large-scale plate structural parts, etc. To achieve the effect of improving plastic toughness at room temperature and improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

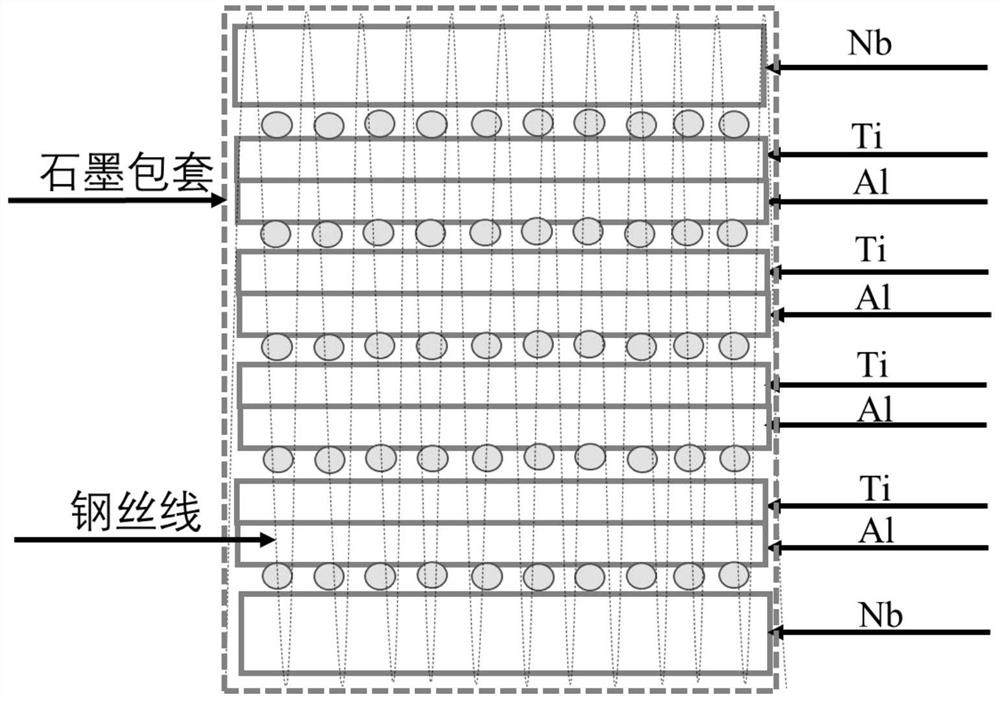

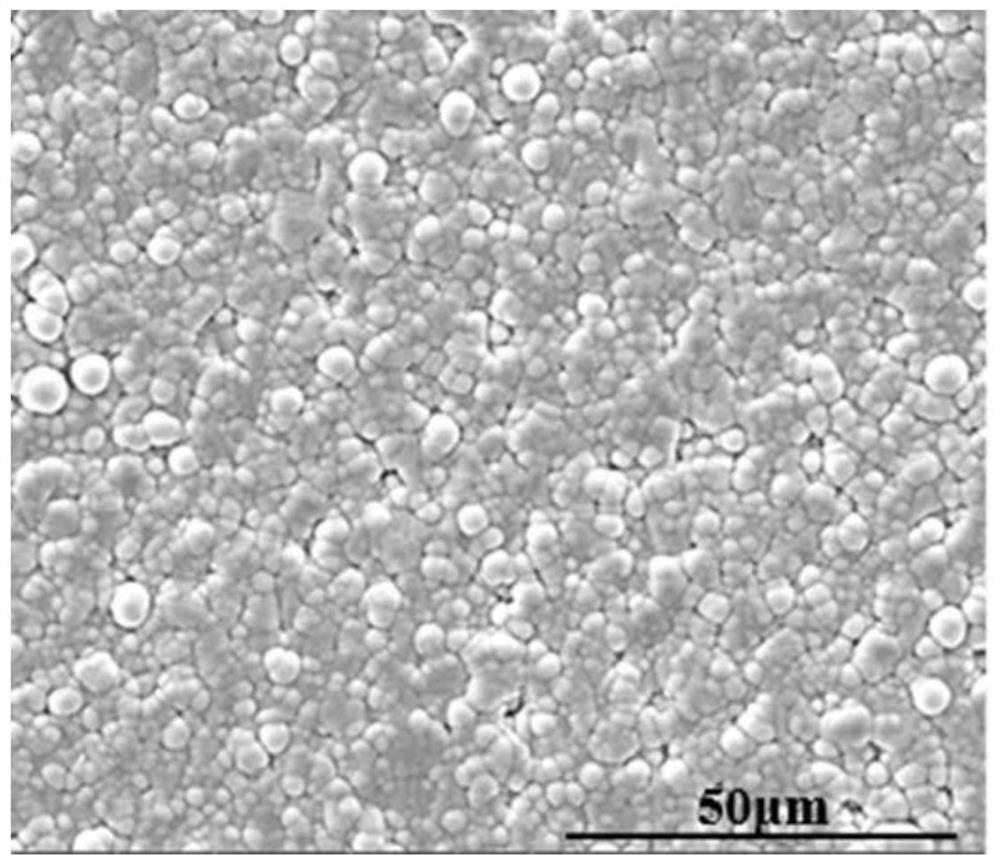

[0024] Specific Embodiment 1: This embodiment describes a Nb / high Nb-TiAl layered composite material, the layered composite material is composed of periodic Nb layers and high Nb-TiAl alloy structure, and Nb is a pure Nb layer , the high Nb-TiAl alloy consists of α 2 -Ti 3 Al and γ-TiAl two-phase composition. The two phases can form a full-lamellar structure with consistent sheet orientation, or one of nearly full-lamellar, dual-state, and equiaxed structures. In the present invention, the α 2 -Ti 3 In the two phases of Al and γ-TiAl, a certain amount of alloying element Nb or other alloying elements except Nb can be solid-dissolved, which can improve the high-temperature performance of the high-Nb-TiAl alloy layer. The metallurgical connection between the Nb layer and the high Nb-TiAl layer of the present invention has a very good connection interface. The unique layered structure in the Nb / high Nb-TiAl layered composite can compensate for the lack of intrinsic propertie...

specific Embodiment approach 2

[0025] Embodiment 2: A method for preparing the Nb / high Nb-TiAl layered composite material described in Embodiment 1, the steps of the method are as follows:

[0026] 1. Use alcohol and acetone to ultrasonically clean Ti foil, Al foil and Nb foil respectively (2000W) for 5 to 10 minutes to remove surface oil, and then use 5vol.% to 15vol.% HF, 100vol.% HF and 5vol.% ~15vol.% NaOH solution to clean the surface of Ti foil, Nb foil and Al foil respectively to remove the scale on the surface, and finally clean it with alcohol ultrasonic (2000W) for 2~5min, then dry it with a hair dryer for later use;

[0027] 2. Use magnetron sputtering to plate Nb or Nb-based alloy film (single-sided coating) on the surface of part of the dried Ti foil and Al foil material by magnetron sputtering (single-sided coating). The Ti foil and Al foil are cut to size, and Ti foil and Al foil are alternately stacked to prepare a high Nb-TiAl alloy layer; the length of the Ti foil and Al foil magnetron s...

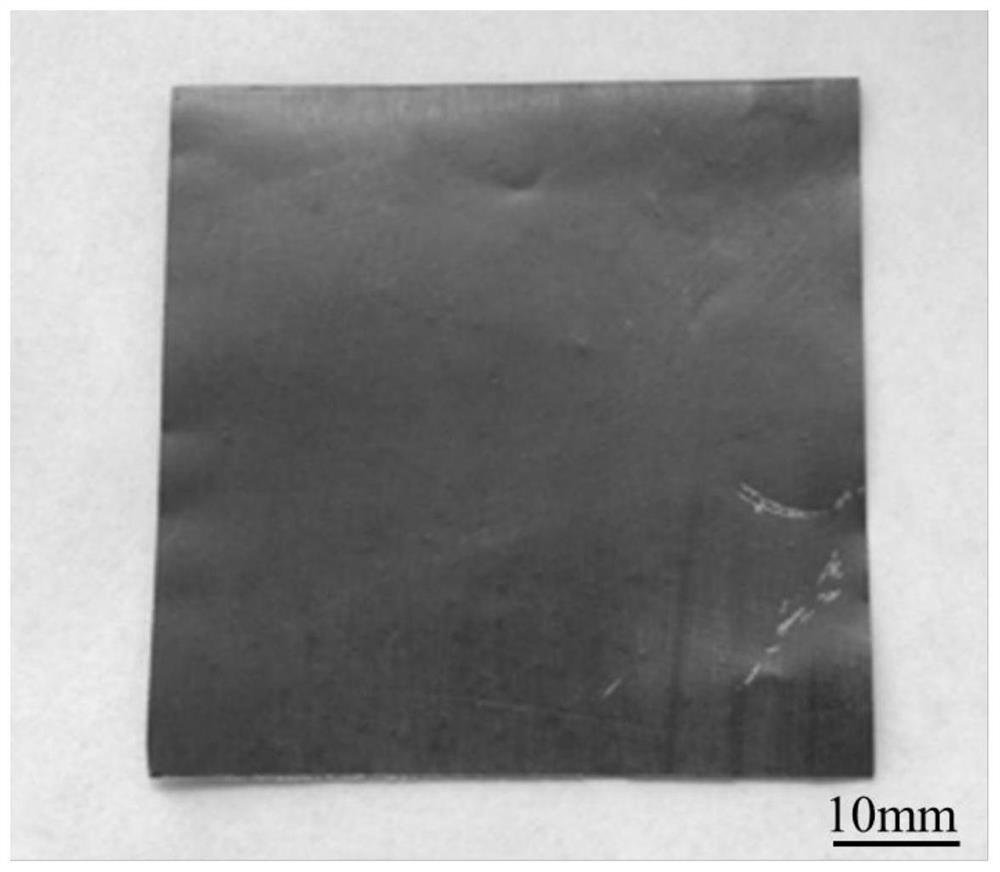

Embodiment 1

[0041] 1. Use alcohol and acetone to clean the Ti foil, Al foil and Nb foil respectively by ultrasonic (2000W) for 8 minutes to remove the oil on the surface, and then use 10vol.% HF, 100vol.% HF and 10vol.% NaOH solutions to clean the Ti foil , Nb foil, and Al foil for surface cleaning to remove surface oxide skin, and finally use alcohol ultrasonic (2000W) to clean for 5 minutes, and blow dry with a hair dryer for later use. The thickness of the Ti foil is 20 μm, the thickness of the Al foil is 18.5 μm, and the thickness of the Nb foil is 25 μm.

[0042] 2. For the structural design of high Nb-TiAl alloys, the method of magnetron sputtering combined with foil metallurgy is used, that is, the Nb target is firstly prepared; after the Nb target is prepared, magnetron sputtering is used on the surface of some Ti foil and Al foil Carry out magnetron sputtering coating, the thickness of the coating is 2.35-2.5 μm; finally, the Ti foil and Al foil after coating are cut to size and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com