Ultra-precise turning method with diamond knife tool hook angle compensation

A diamond tool and ultra-precision technology, applied in the fields of ultra-precision machining and complex parts manufacturing, can solve the problems of low fracture toughness, low production efficiency and poor machinability of brittle materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

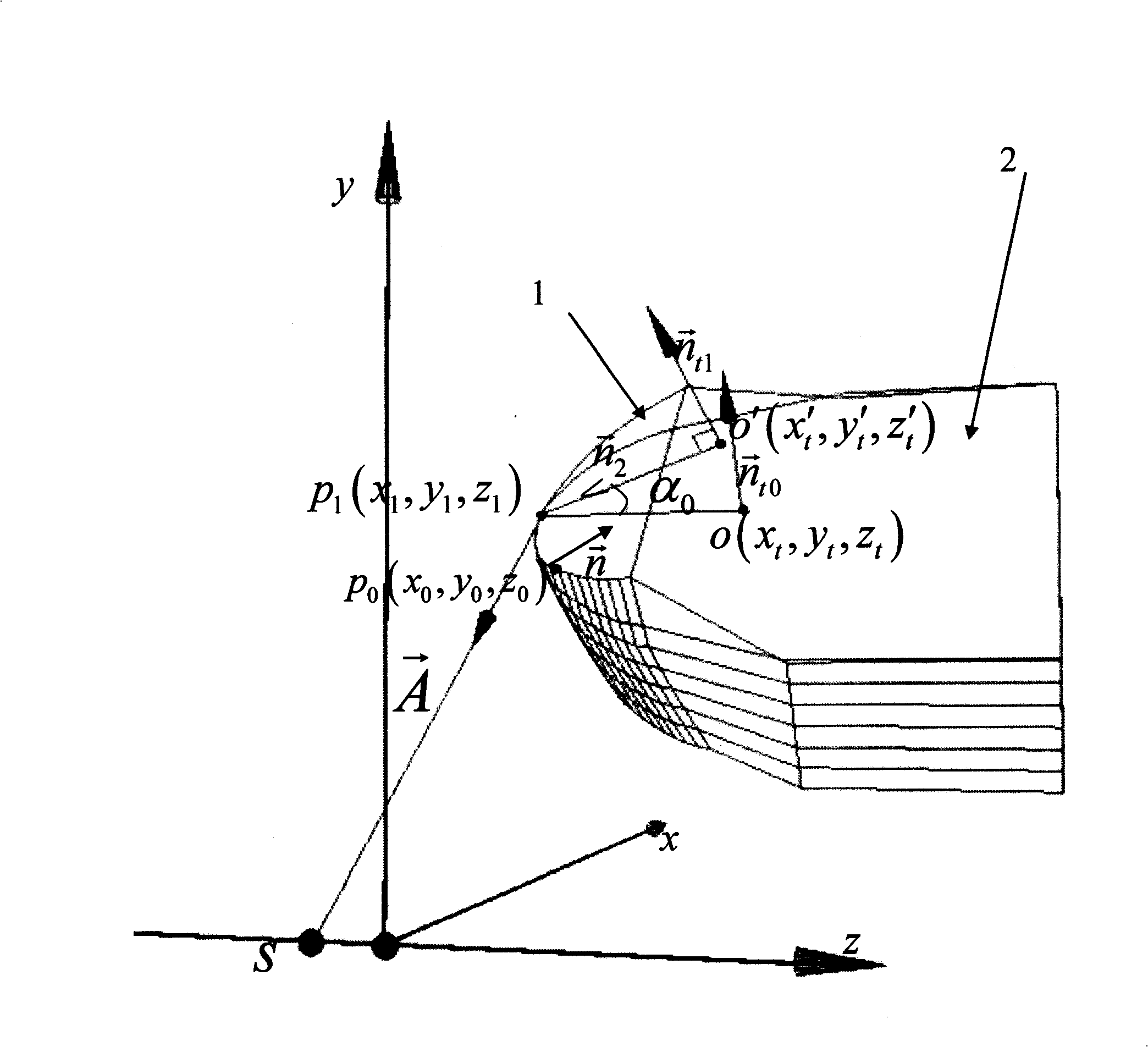

[0023] The tool model considering the rake angle is as follows figure 1 shown. In the figure, 1 is the cutting surface, and 2 is the zero rake angle surface. The radius of the tool nose arc on the cutting surface is r 0 ;Established at the center of the arc of the cutting surface figure 1 In the tool coordinate system o′x′y′z′ shown, the angle between the cutting surface and the negative direction of the z-axis is the rake angle α 0 , the current cutting surface can be regarded as a zero-rake angle surface formed by rotating around the axis parallel to the tool nose and the x-axis. The normal vector of the cutting surface is,

[0024] n → t = ( 0 , cos α 0 , sin α 0 ) - - - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com