Silencing cover for lathe

A sound-absorbing cover and lathe technology, applied in the direction of turning equipment, tool holder accessories, maintenance and safety accessories, etc., can solve the problems of staff discomfort and adverse effects of operators, and achieve the effect of reducing processing noise and reducing irritability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

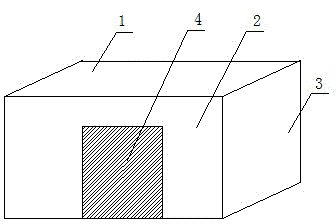

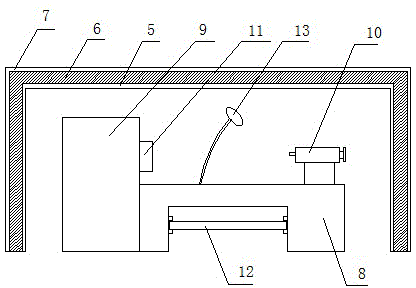

[0014] A sound-absorbing cover for a lathe, the sound-absorbing cover is formed by a plurality of panels to form a frame, such as figure 1 , the muffler cover includes a top panel surface 1, a left panel surface 2, a right panel surface, a front panel surface 3, and a rear panel surface, and each panel surface includes an inner surface layer 5, a filling layer 6, and an outer surface layer 7 that are set and bonded, Both the inner surface layer 5 and the outer layer 7 are made of sound-absorbing panels, the filling layer 6 is made of sound-absorbing cotton or sound-absorbing felt, the left panel 2 is provided with a single door 4, and one side of the single door 4 is movably connected to the left panel 2, and the single door 4 The hollow double-layer transparent board is made of acrylic, and the middle part of the right board is provided with an observation window, and the observation window is made of a hollow double-layer transparent board made of acrylic.

[0015] The noise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com