Robot sawing and milling system for automobile doorsill beam structural part

A technology of threshold beams and structural parts, applied in the field of robotic sawing and milling systems, can solve problems such as low processing efficiency, long processing cycle time, and large equipment footprint, and achieve the effects of reducing work intensity, improving processing efficiency, and optimizing the overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

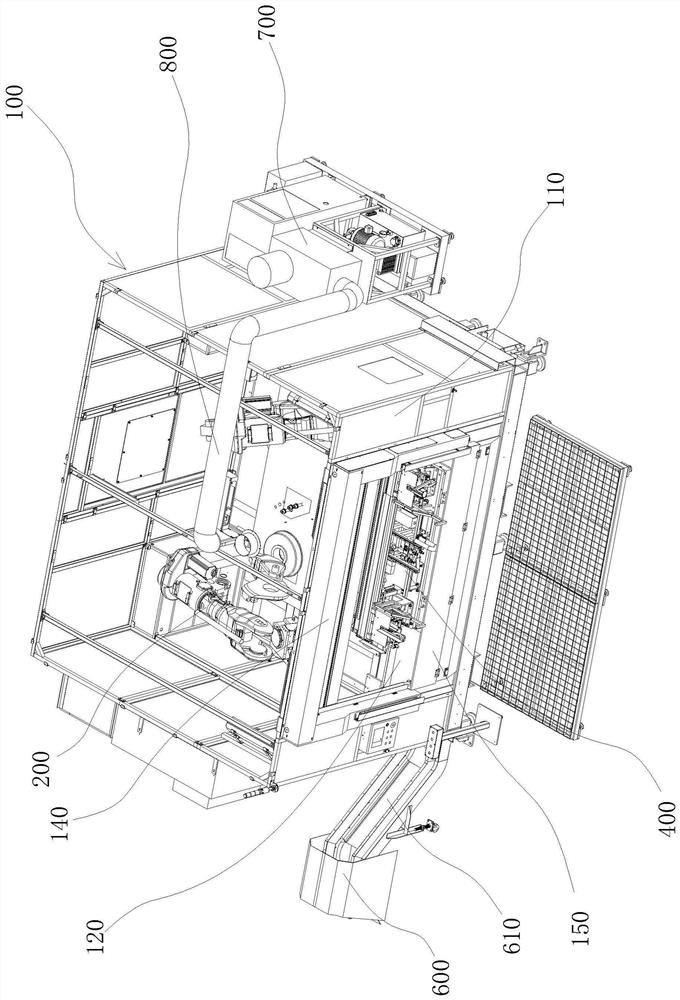

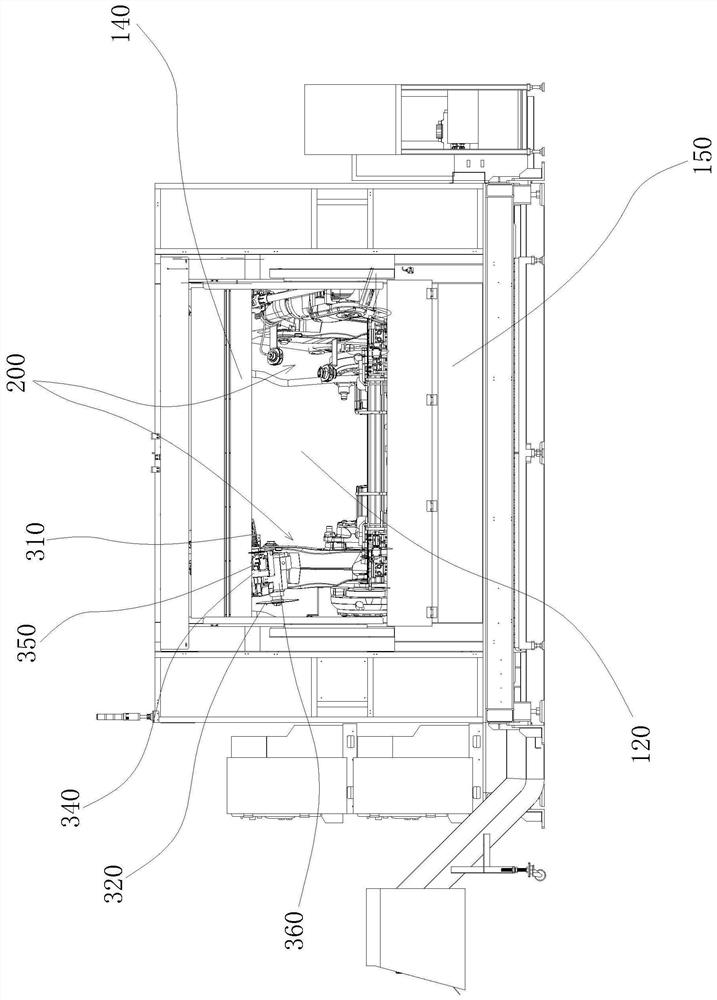

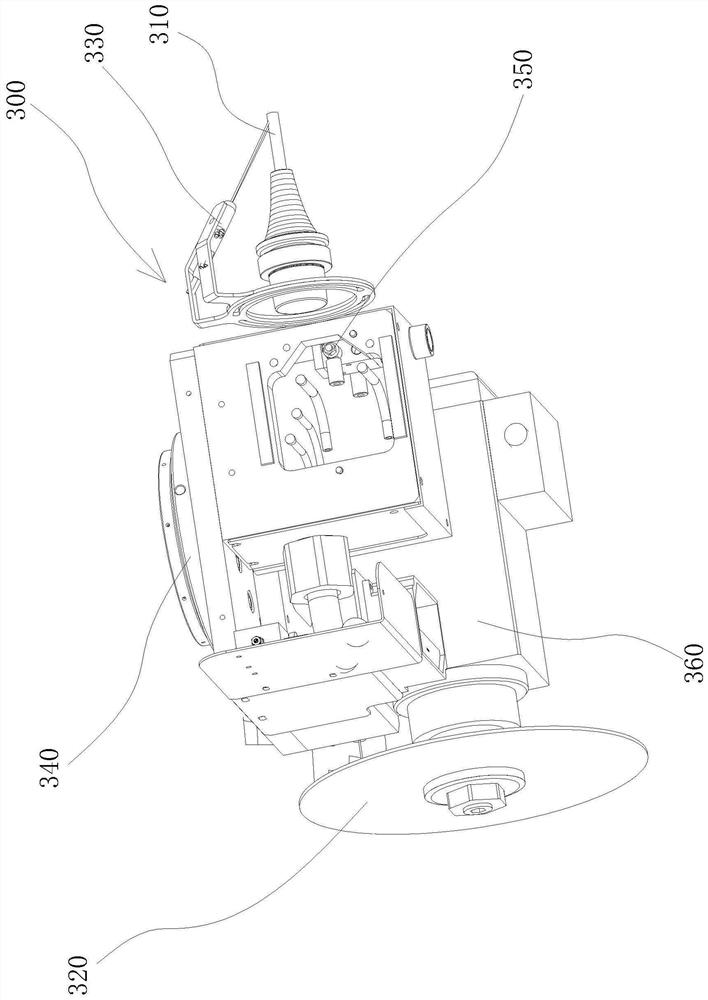

[0038] like Figure 1-8 As shown, a robot sawing and milling system for automotive door sill beam structures includes: a machine platform 100, a robot body 200, which is installed on the machine platform 100; a tool assembly 300, which includes a power head, a milling cutter 310, Saw blade 320 and oil mist nozzle 330, the power head and the oil mist nozzle 330 are connected to the robot body 200, the milling cutter 310 and the saw blade 320 are linked to the power head; Milling fixture 400, which is installed on the machine platform 100 and used to fix the workpiece; chip removal machine 600, which is connected to the bottom of the machine platform 100 and used to discharge cutting waste; oil mist collection device, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com