Numeric control lathe

A technology of CNC lathes and machine tools, applied in the field of CNC lathes, can solve problems such as axial movement, achieve the effects of improving performance, eliminating axial movement, and reducing processing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

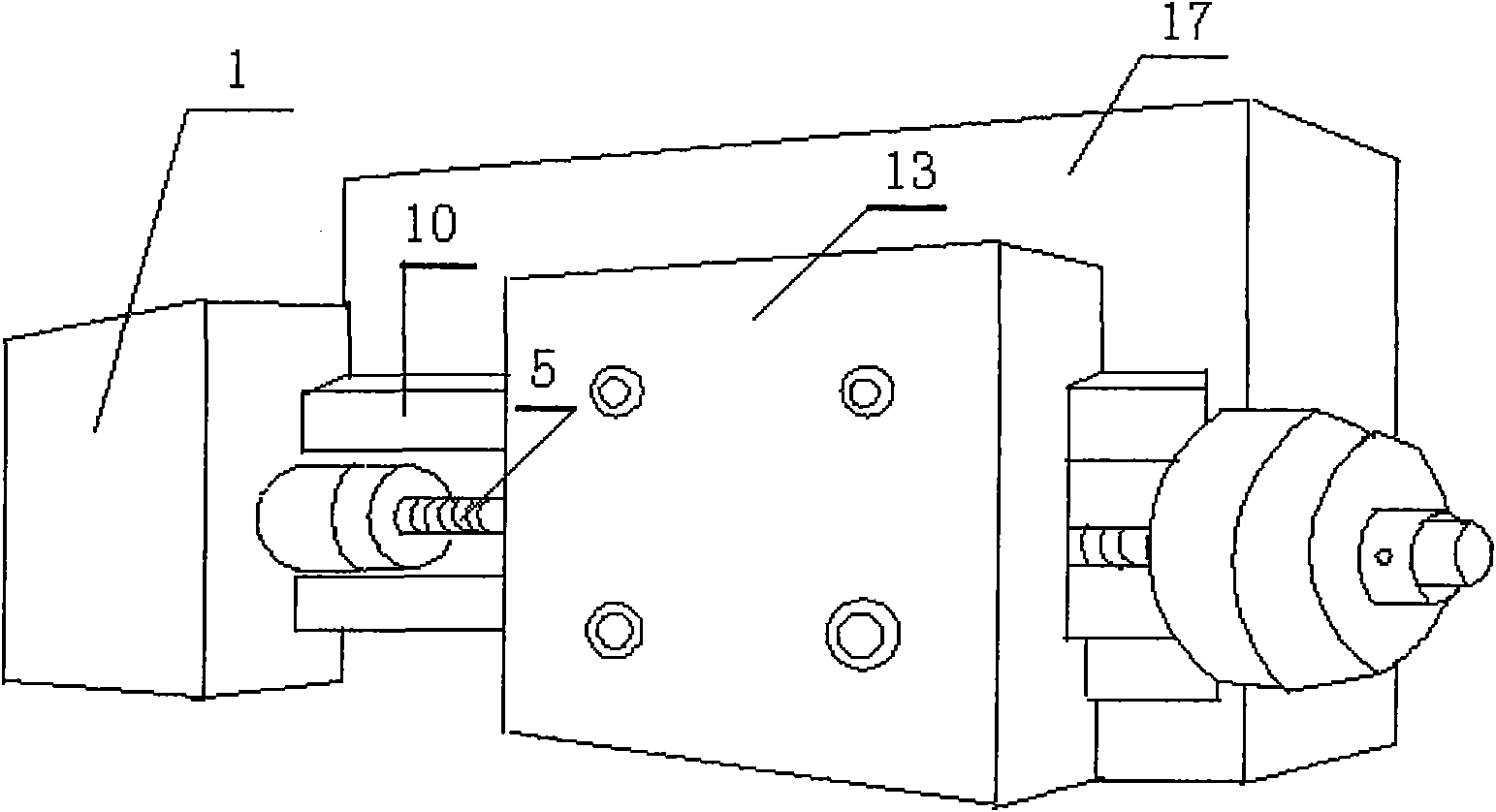

[0012] Example: as attached figure 1 As shown, the present invention relates to a kind of numerically controlled lathe, comprises machine tool 17, workbench 13, the drive motor 1 of workbench, and workbench 13 is installed on the guide rail 10 of lathe, is arranged in parallel between the bottom of workbench, two guide rails 10 There is a threaded rod 5, one end of the threaded rod 5 is fixed by a support, and the other end is connected with the motor 1 through an axial clearance adjusting device.

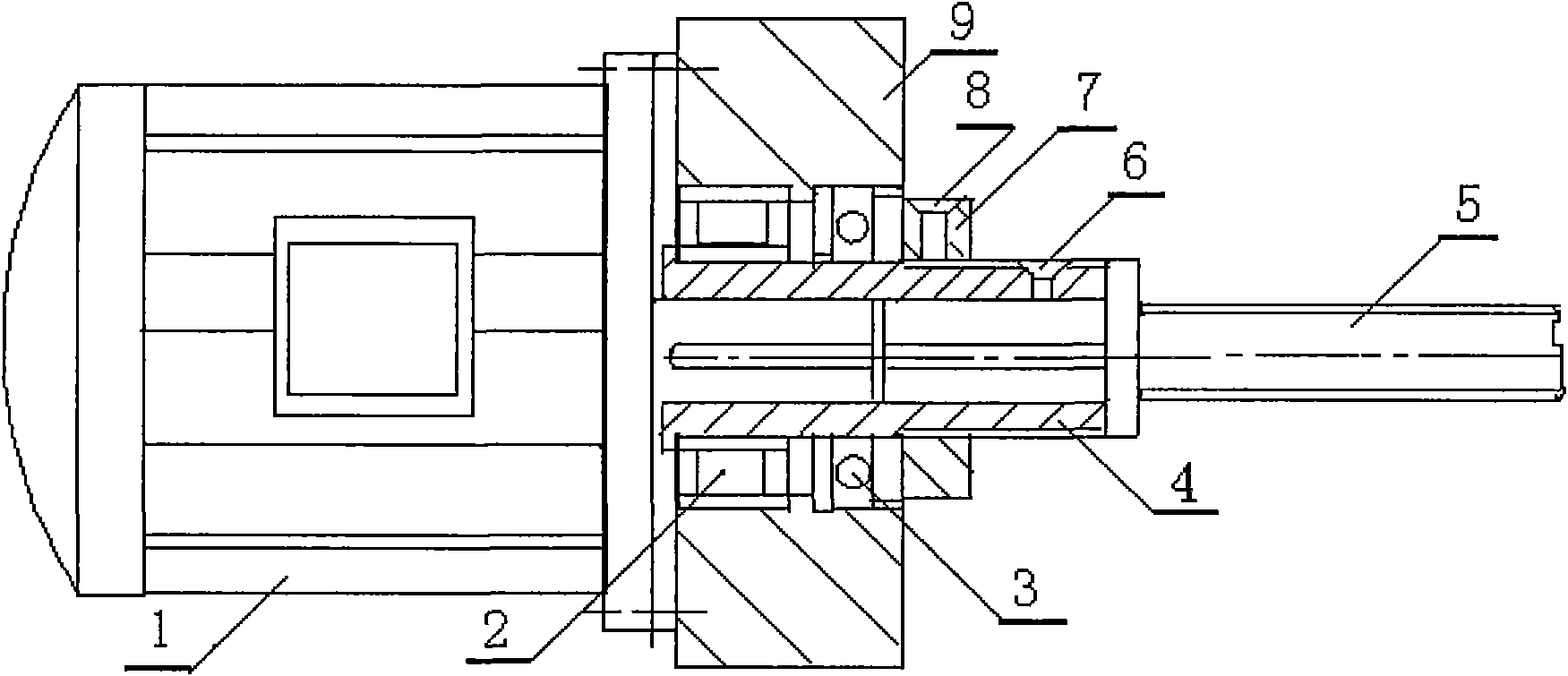

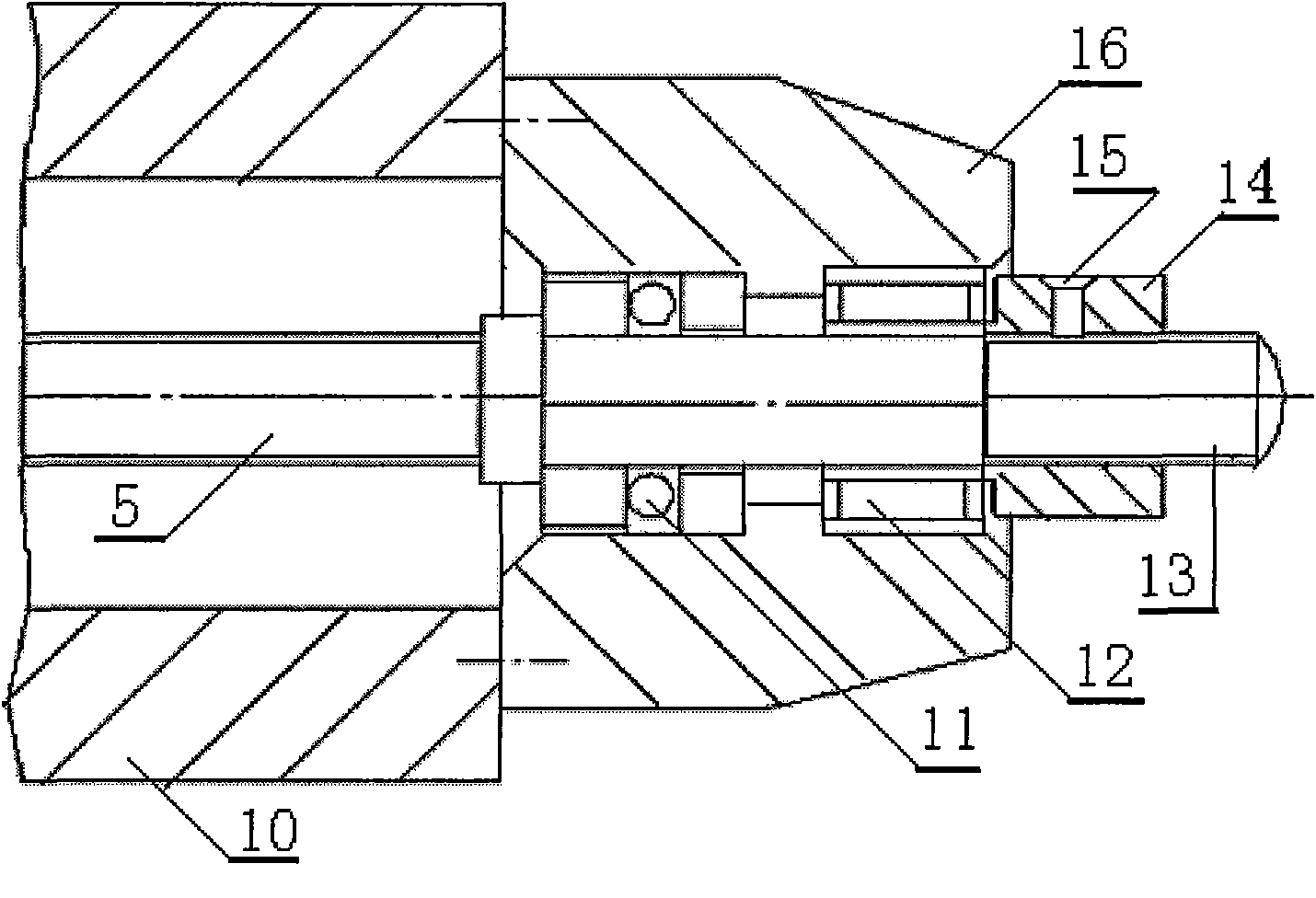

[0013] Such as figure 2 As shown: the axial clearance adjustment device includes ball bearing 2, plane bearing 3, bushing 4, cap 7, and bearing seat 9; the output shaft of driving motor 1 and screw 5 are installed in the inner hole of the same bushing 4 It is fixed with a key, and the ball bearing 2, the plane bearing 3 and the cap 7 are installed on the outer circle of the shaft sleeve 4 from the motor end, and the ball bearing 2 and the plane bearing 3 are inscribed with the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com