Power head for digital control hole drilling

A power head and power system technology, which is applied in the field of hole processing equipment and CNC drilling power head, can solve the problems of high equipment cost, low efficiency, and poor versatility of ordinary drilling power heads, and achieve simple operation, convenient disassembly, Improve the effect of installation and debugging inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

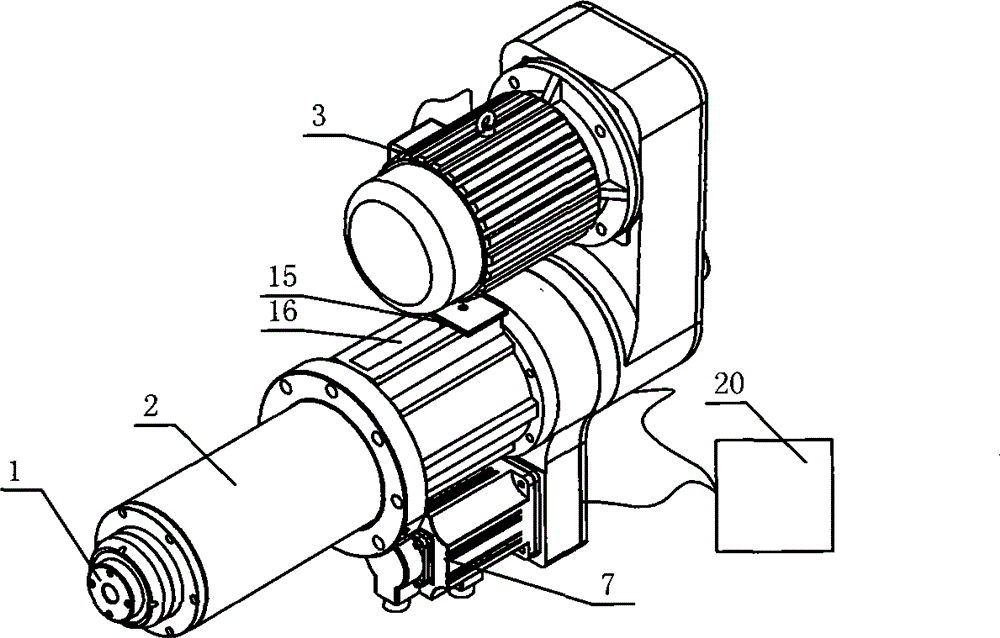

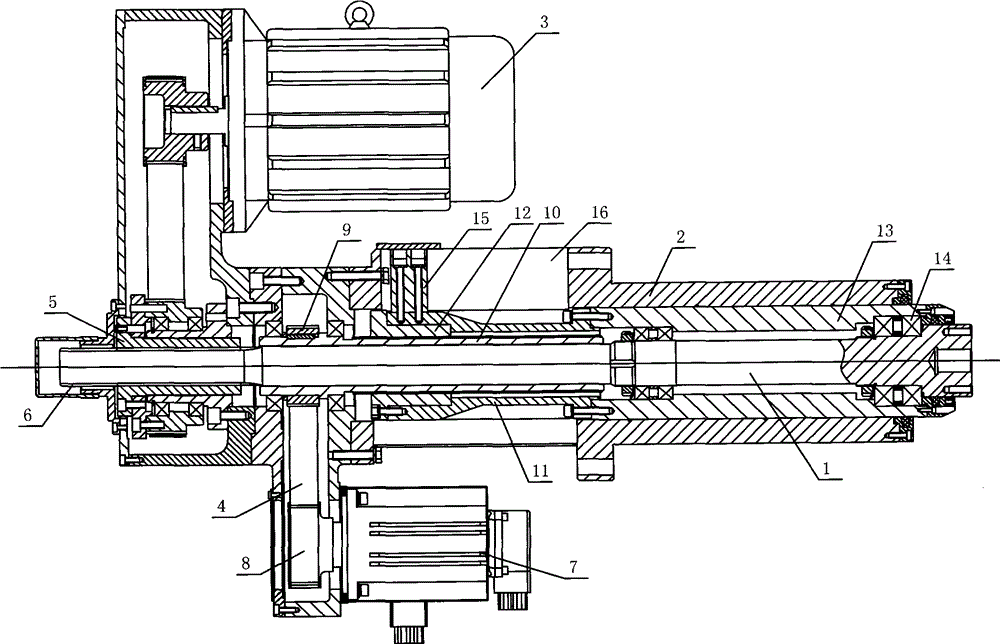

[0019] Attached below figure 1 , figure 2 The present invention is further described:

[0020] The numerically controlled drilling power head of the present invention includes a housing 2 , a main shaft 1 disposed on the housing 2 , a main shaft transmission system connected to the main shaft 1 , a power tooth transmission system and a numerical control 20 . The main shaft 1 and the main shaft transmission system are horizontally and vertically arranged. The main shaft transmission system mainly includes a three-phase asynchronous motor 3 and a main shaft transmission wheel 5. While the main shaft transmits the rotational movement, the axial direction of the main shaft must be kept relatively movable. Here, the axial movable connection mechanism is a spline transmission mechanism that engages with each other. The combination of the keyway 6 can not only transmit the rotational motion of the three-phase asynchronous motor 3 in the main shaft transmission system to the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com