Drilling, punching and tapping all-in-one machine for square and round flange end plates

A flange end and integrated machine technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low efficiency and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

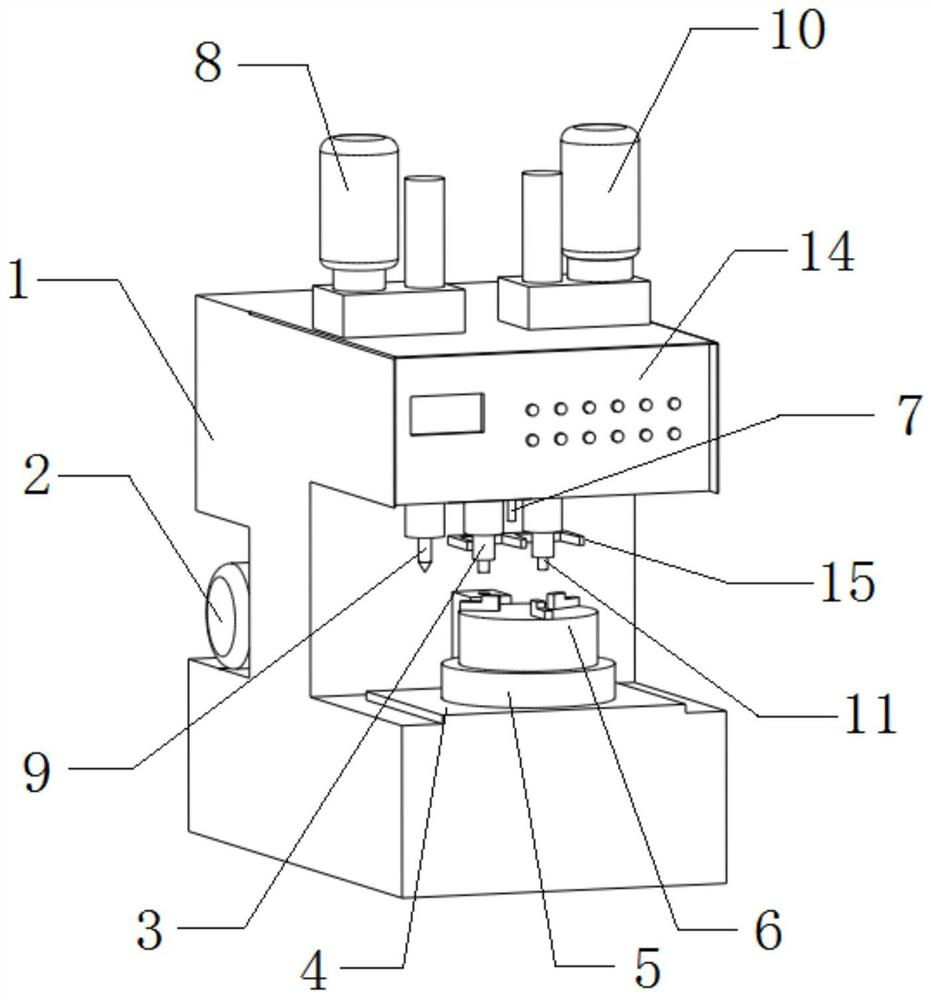

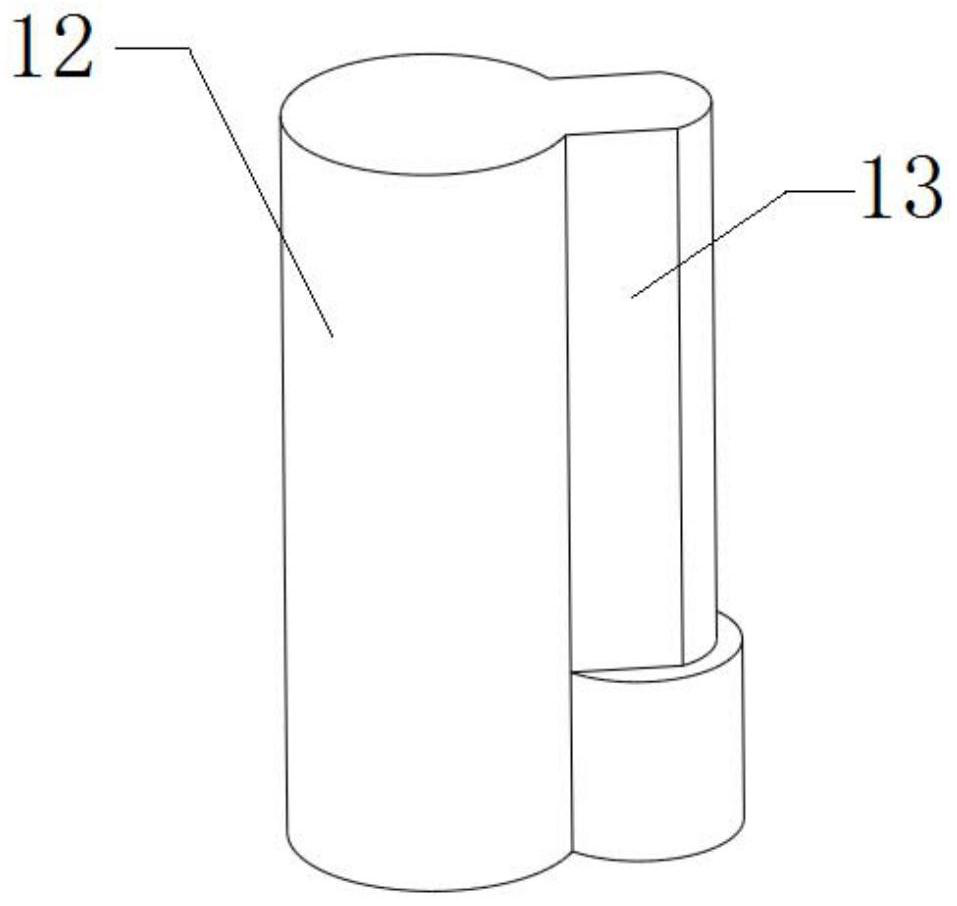

[0019] Example 1, such as Figure 1 to Figure 2 As shown, the square and round flange end plate drilling, punching, and tapping teeth integrated machine includes a CNC punching machine 1, a punching knife fixing rod 3 that can move up and down in transmission connection with the CNC punching machine drive motor 2, and a punching knife The fixed rod 3 is detachably provided with a punching punch; the lower part of the punching head is provided with an operation table 4, and the operation table is provided with a numerical control indexing plate 5, a rotary oil cylinder hydraulic chuck 6, a numerical control indexing plate 5, and a rotary oil cylinder The hydraulic chuck 6 is fixed by the clamping assembly, and the numerical control indexing plate 5 is driven by the indexing plate drive motor;

[0020] The drilling assembly and the tapping assembly are arranged on the upper die assembly, the drilling assembly includes a drilling drive motor 8 and a drill bit 9, the tapping assem...

Embodiment 2

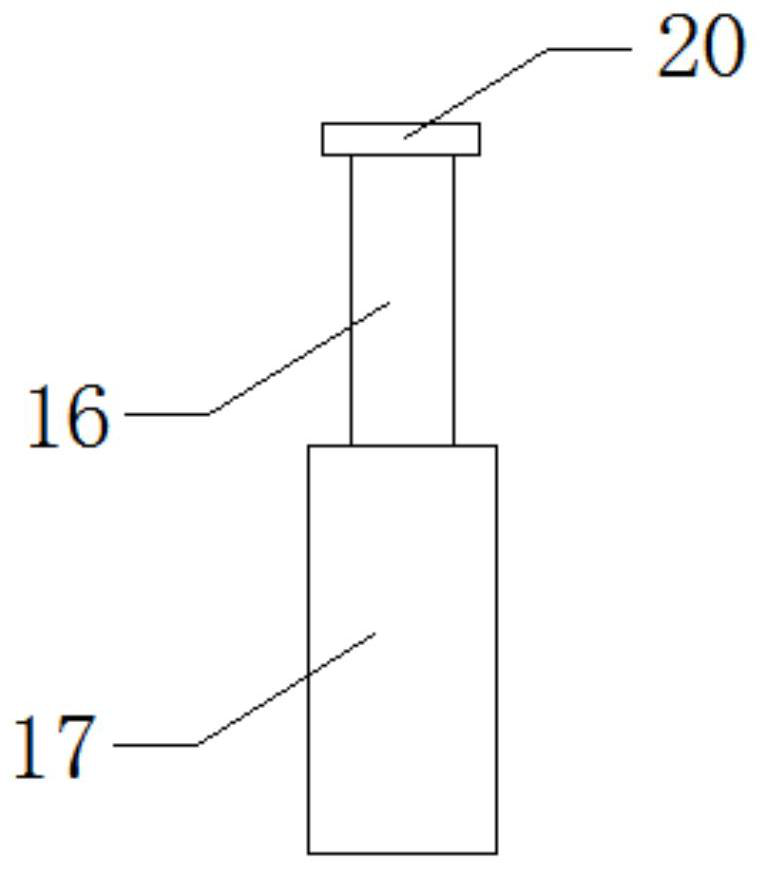

[0023] Example 2, such as Figure 3-4 As shown, the workpiece disc of this embodiment adopts a vertical clamping device. Except that the workpiece disc is different from the hydraulic chuck of the rotary cylinder in Embodiment 1, other parts are evenly the same as in Embodiment 1. The vertical clamping device includes a positioning column 16, a hydraulic cylinder 17 and the locking plate, the hydraulic cylinder 17 is located on the positioning base plate, the positioning column 16 is located on the top of the hydraulic cylinder 17, the locking plate includes a disc 18, and the disc 18 is provided with a draw-in groove 19 plugged with the positioning column 16, Positioning column 16 tops are integrally provided with a gland 20 and the diameter of gland 20 is greater than the width of draw-in groove 19, and positioning column 16 cooperates with locking plate to lock flange plate on the numerically controlled indexing plate 5, and disc 18 is also provided with There is a handle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com