Efficient environment-friendly roll crusher and working method thereof

A double-roller crusher, an environment-friendly technology, applied to cleaning methods and appliances, chemical instruments and methods, and dust removal, etc., can solve problems such as high working noise, dust escape from the crushing box, and large environmental pollution in the surrounding environment. Large dust, enhanced crushing effect, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

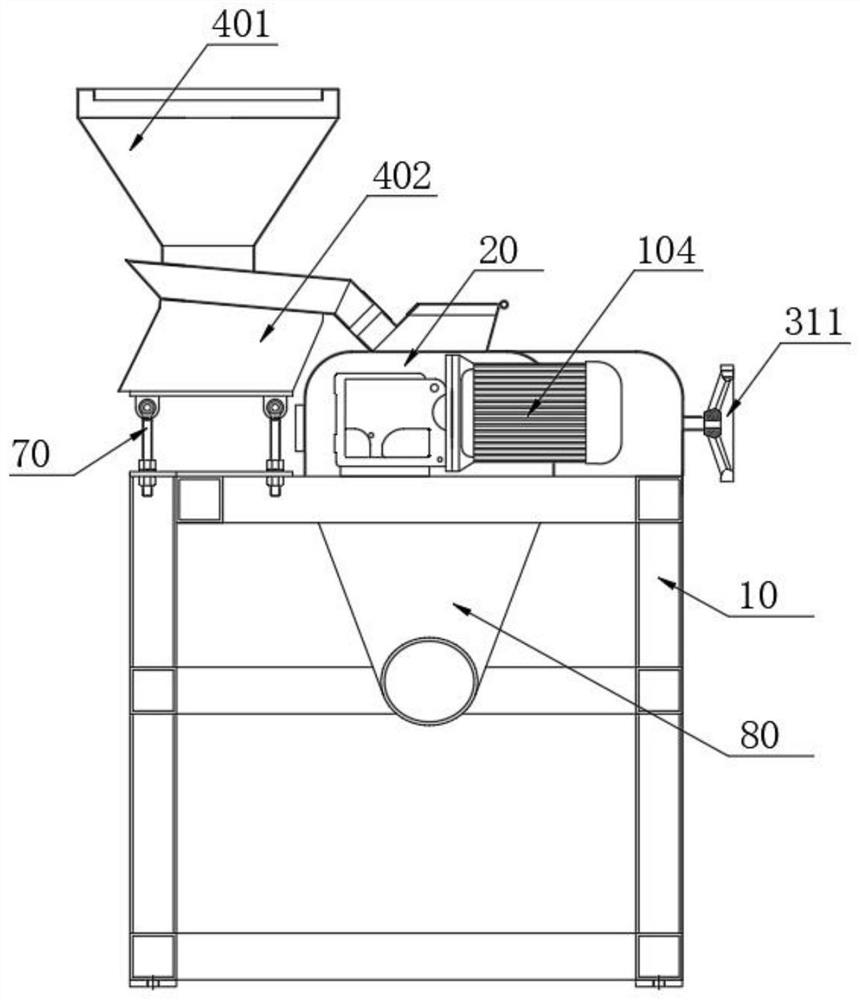

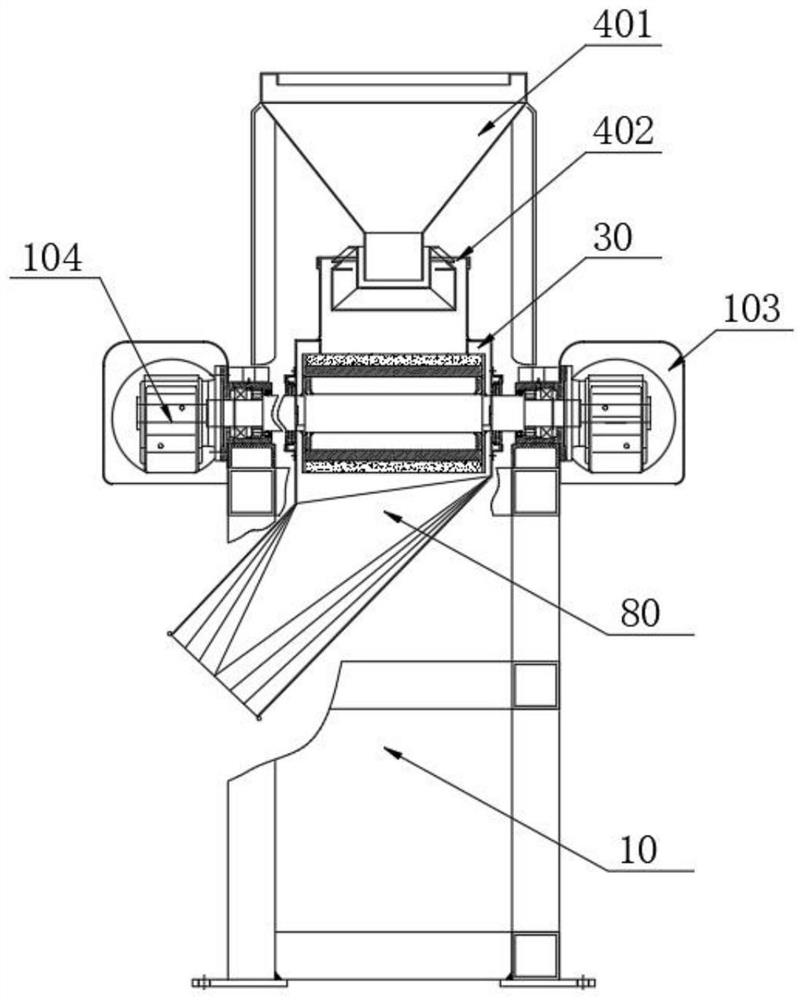

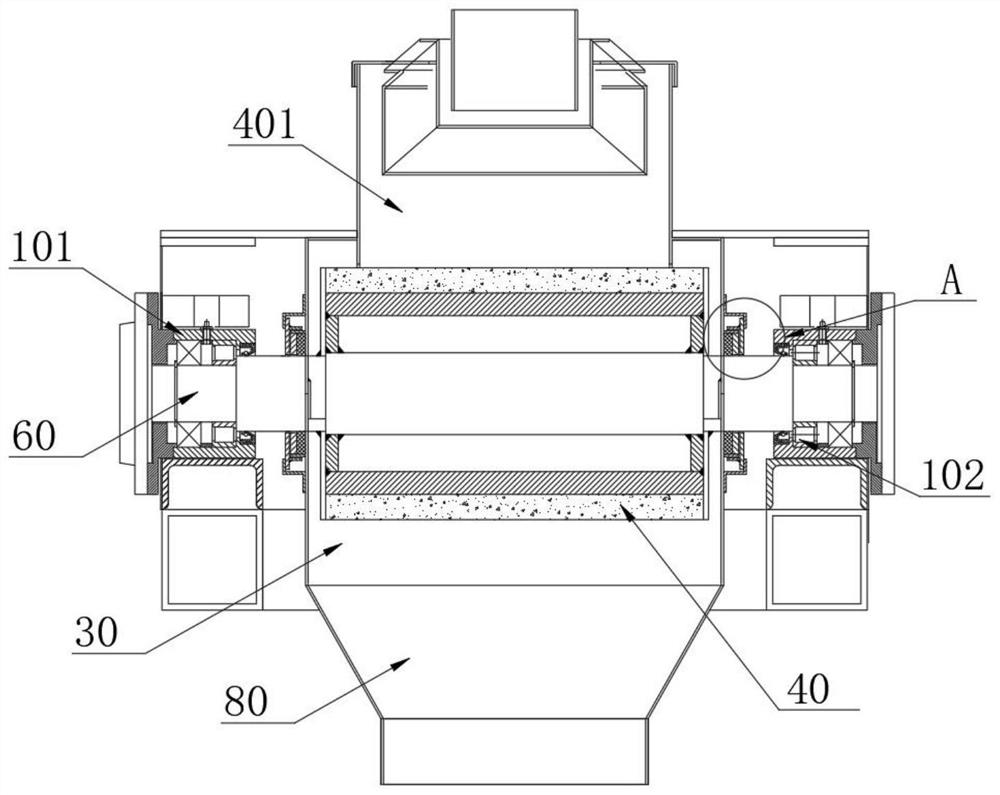

[0041] see Figure 1-8As shown, a high-efficiency environment-friendly double-roll crusher includes a frame 10, two fixed boxes 20 are symmetrically arranged on the front and back of the top of the frame 10, and a crushing box 30 is arranged between the two fixed boxes 20, wherein the fixed The top of the box 20 is provided with a detachable top plate through bolts, and the inside of the fixed box 20 can be easily maintained by removing the top plate. The interior of the crushing box 30 is provided with a first crushing roller 40 and a second crushing roller 50 respectively, and the inside of the two first crushing rollers 40 and the second crushing roller 50 are all provided with a rotating shaft 60, wherein the first crushing roller 40 and the second crushing roller 50 The second crushing rollers 50 all adopt ceramic rollers. The top of the frame 10 and the left side of the crushing box 30 are provided with a fixed seat 70, and the top of the fixed seat 70 is provided with ...

Embodiment 2

[0049] In the present invention, the feeding assembly includes a feeding hopper 401, and a vibrating feeder 402 is arranged below the feeding hopper 401, wherein the vibrating feeder 402 adopts an electromagnetic vibrating feeder 402. The bottom end of the feed hopper 401 extends to the inside of the vibrating feeder 402, and the right side of the vibrating feeder 402 is provided with an adjusting knife door 403, and the right side of the vibrating feeder 402 is provided with a dust removal cloth pipe 404, And the bottom end of the dust removal cloth pipe 404 is provided with a feeding box 405, the bottom of the feeding box 405 communicates with the interior of the crushing box 30, and the top of the feeding box 405 is provided with a cover plate 406 for rotation;

[0050] When in use, feed material to the inside of the vibrating feeder 402 through the feed hopper 401, the vibrating feeder 402 vibrates the material evenly, and at the same time use the adjustment knife door 403 ...

Embodiment 3

[0052] In the present invention, motor covers 103 are provided on the front and rear sides of the top of the frame 10, and the insides of the two motor covers 103 are provided with reducers 104, wherein the reducer 104 is a K series hardened reducer 104. One ends of the output shafts of the two reducers 104 are respectively fixedly connected to one ends of the two rotating shafts 60 through couplings, and the two rotating shafts 60 are driven by the two reducers 104 to rotate in opposite directions, so that the first crushing roller 40 and the The second crushing roller 50 rotates in opposite directions in the crushing box 30 to realize the crushing process of the material. In addition, the mechanical efficiency can be further improved and the processing noise can be reduced by using the hard tooth surface reducer 104 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com