Anti-fracture titanium alloy milling cutter

A titanium alloy, anti-fracture technology, applied in the field of mechanical processing, can solve problems such as titanium alloy milling cutter fracture, achieve the effect of improving safety and preventing debris from splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

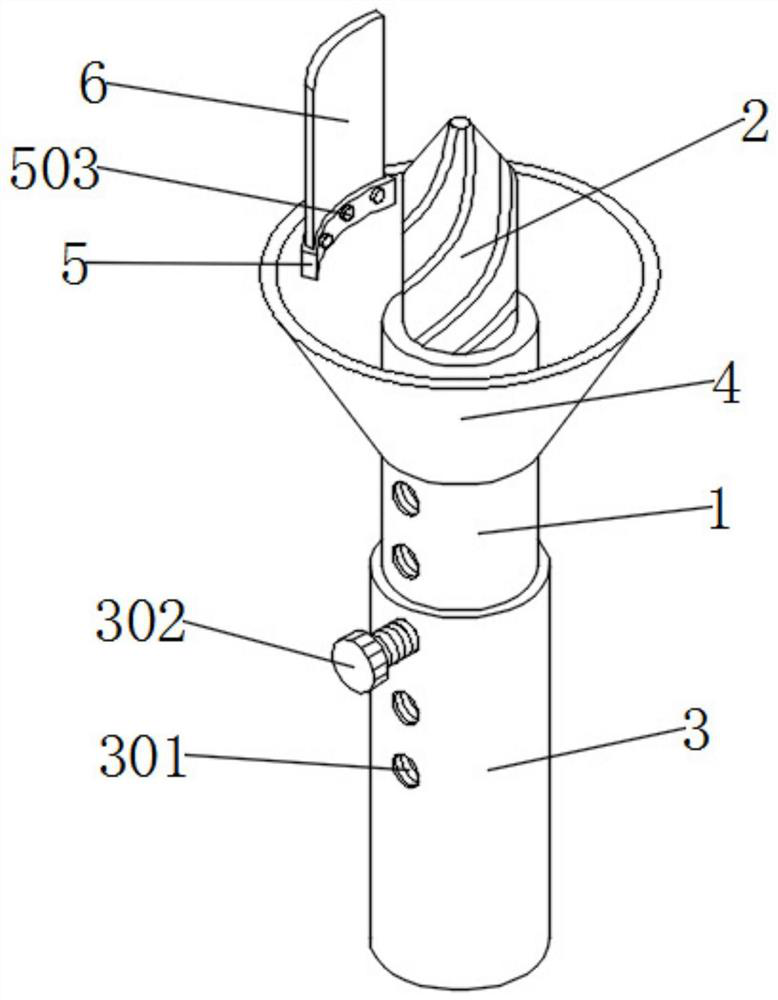

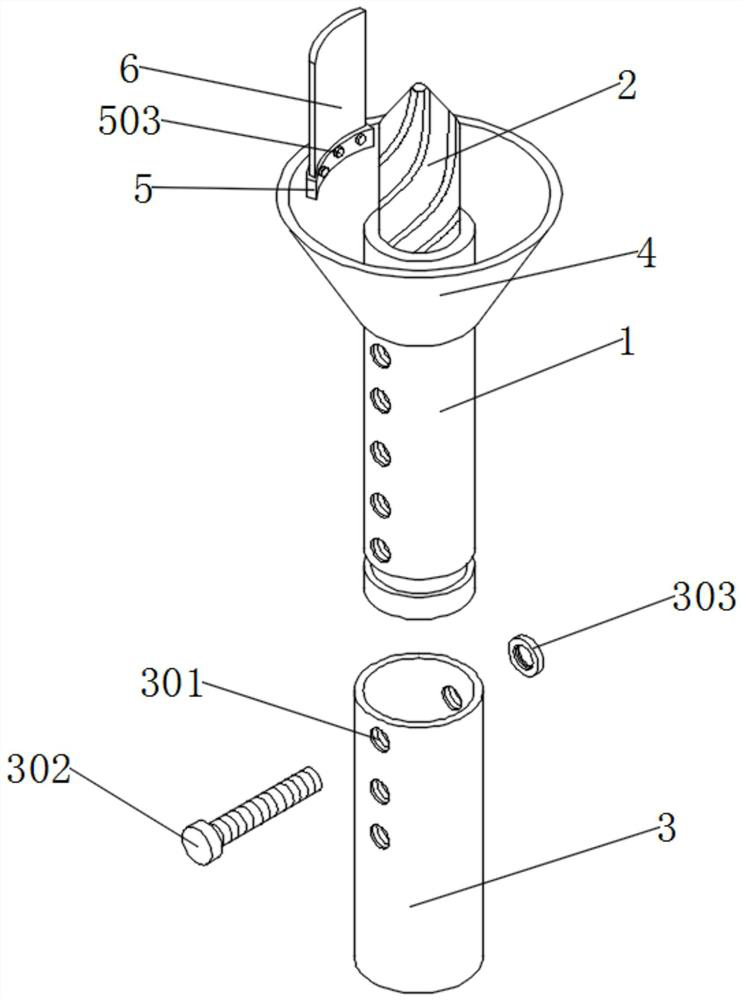

[0031] see figure 1 with figure 2 , an embodiment provided by the present invention: a fracture-resistant titanium alloy milling cutter, comprising a milling cutter body 1, a milling cutter head 2 and a protective sleeve 3, the diameter of the milling cutter main body 1 is smaller than the diameter of the protective sleeve 3, and the milling cutter The top of the main body 1 is equipped with a milling cutter head 2, and the milling cutter head 2 is located inside the shield 4, the outer surface of the milling cutter main body 1 is sleeved with a protective sleeve 3, and the outer surface of the protective sleeve 3 and the milling cutter main body 1 both penetrate A first connection hole 301 is provided, and the inner surface of the first connection hole 301 is provided with threads. The inside of the first connection hole 301 is installed with a threaded rod 302 , and one end of the threaded rod 302 is threaded with a nut 303 .

[0032] Specifically, first insert the milling...

Embodiment 2

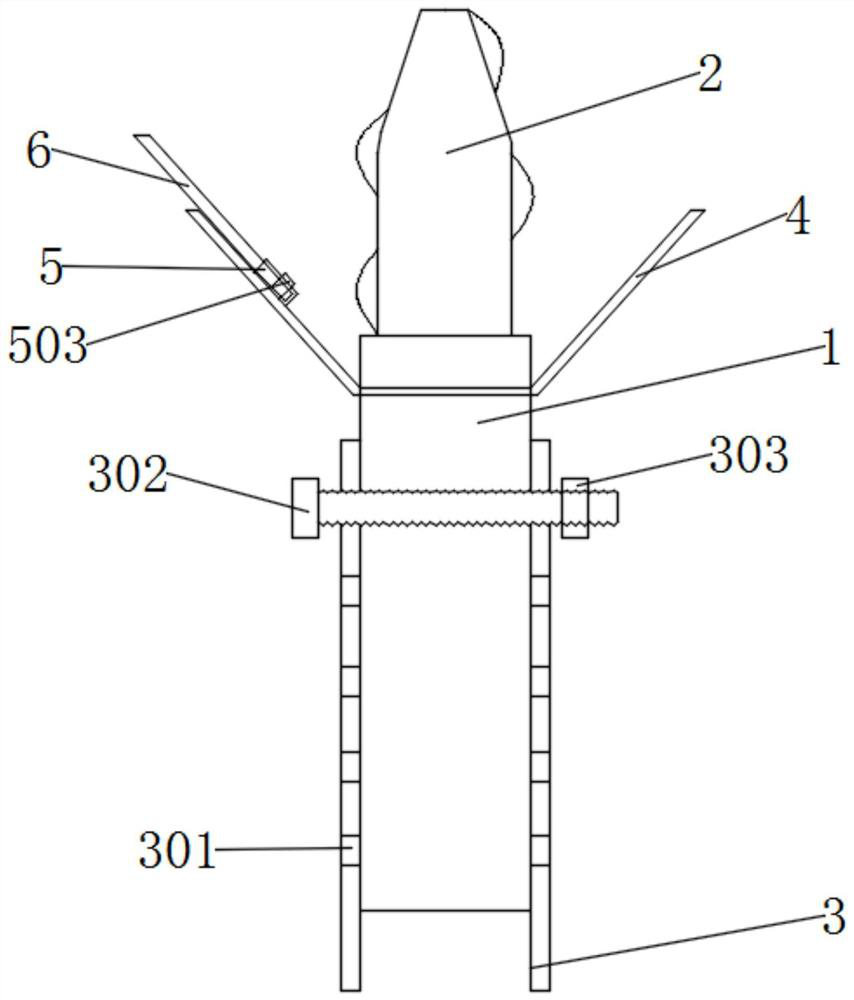

[0034] as attached image 3 As shown, a fracture-proof titanium alloy milling cutter includes a shield 4, the shield 4 is installed on the outer surface of the milling cutter body 1, and the shield 4 is located under the protective cover 3, and the shield 4 is trumpet-shaped.

[0035] Specifically, with the high-speed rotation of the milling cutter main body 1, a part of the chips produced by the milled object will fly out under the drive of the milling cutter head 2, and when the chips fly outward, they will meet with the inside of the shield 4. The surface collides and falls on the workbench of the object to be milled, which can effectively prevent the impact of debris flying on the milling work, and to a certain extent provide convenience for subsequent workers to clean up the site.

[0036] as attached Figure 4 As shown, a kind of anti-fracture titanium alloy milling cutter includes a storage block 5 and a brush 6, a storage block 5 is installed on the inner surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com