Cement compression test device

A compressive test, cement technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of debris splashing and hurting people, difficult cleaning, and affecting the accuracy of detection data, etc., to achieve Avoid debris splashing and the effect of debris hurting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

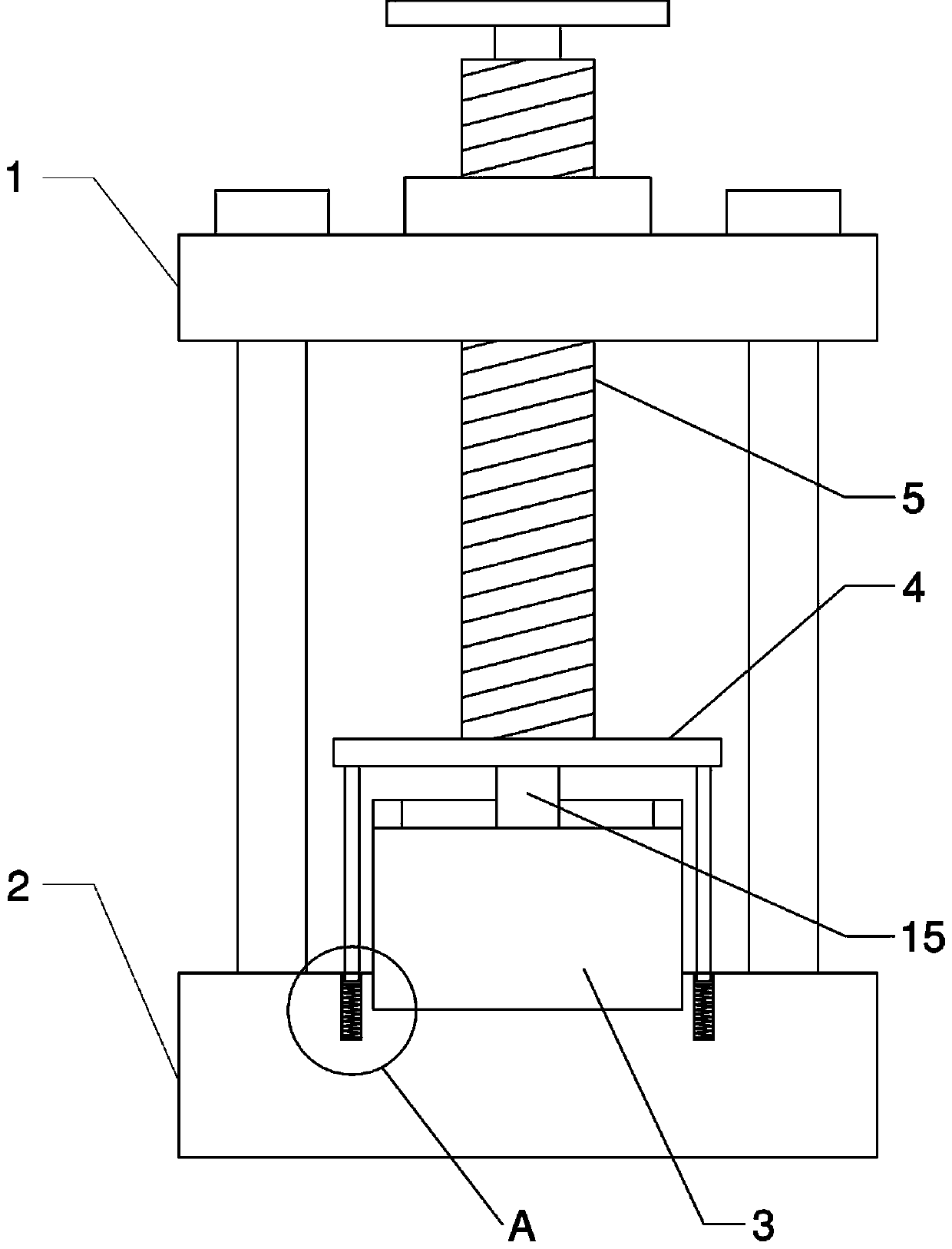

[0022] Such as figure 1 Among them, a cement compression test device includes a frame 1, the frame 1 is fixedly arranged on the base 2, the base 2 is also provided with a test block support platform 3, the frame 1 is provided with a threaded column 5, and the threaded column 5 The lower end is provided with an upper platen 4, and the upper platen 4 and the test block support table 3 are arranged on the same vertical plane;

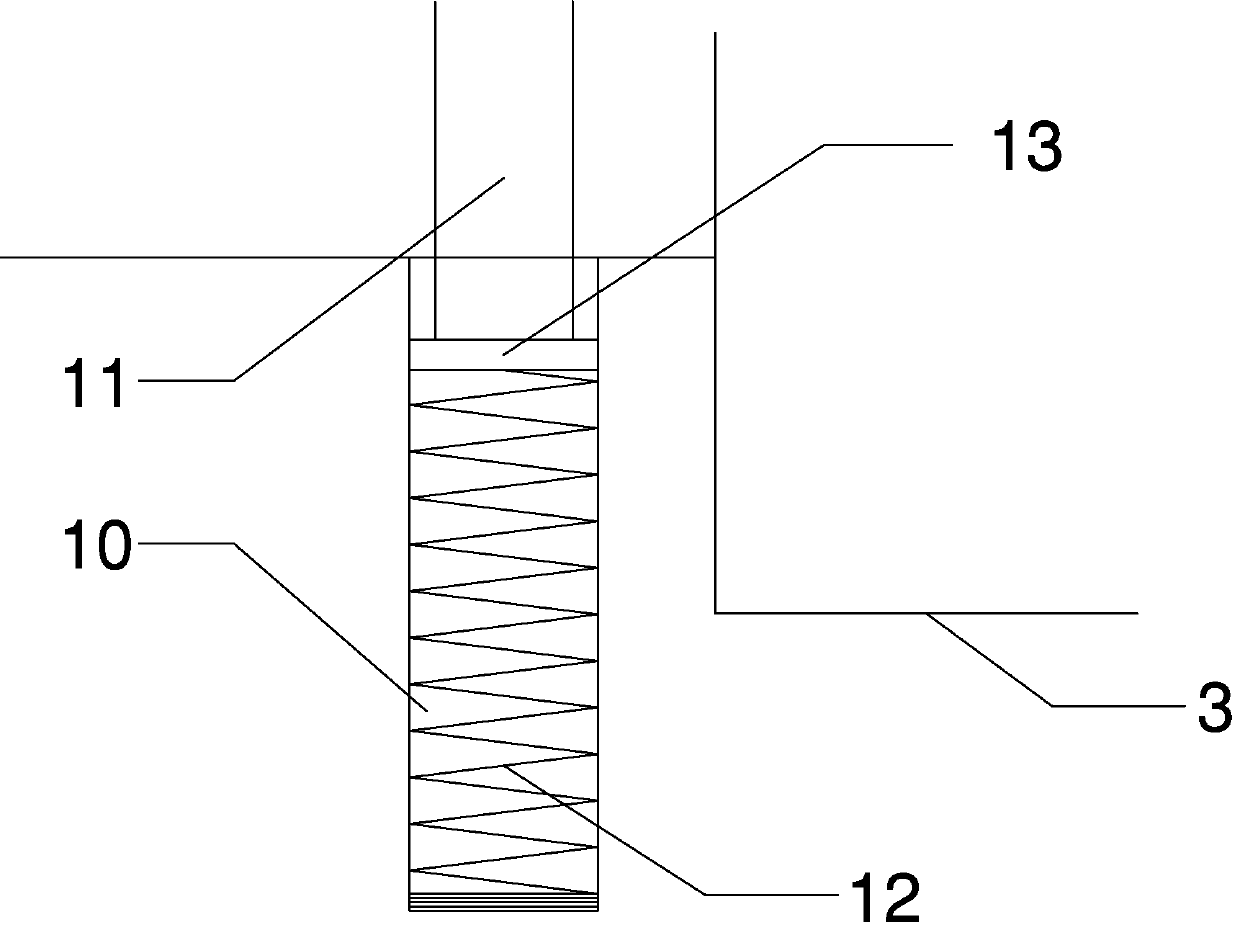

[0023] The bottom surface of the upper platen 4 is provided with a protective plate 11, the protective plate 11 adopts a cylindrical structure with a rectangular cross-section, and its cross-sectional size is larger than that of the test block support table 3, and the base 2 is provided with a groove 10 for protection. The lower end of the plate 11 can extend into the groove 10 .

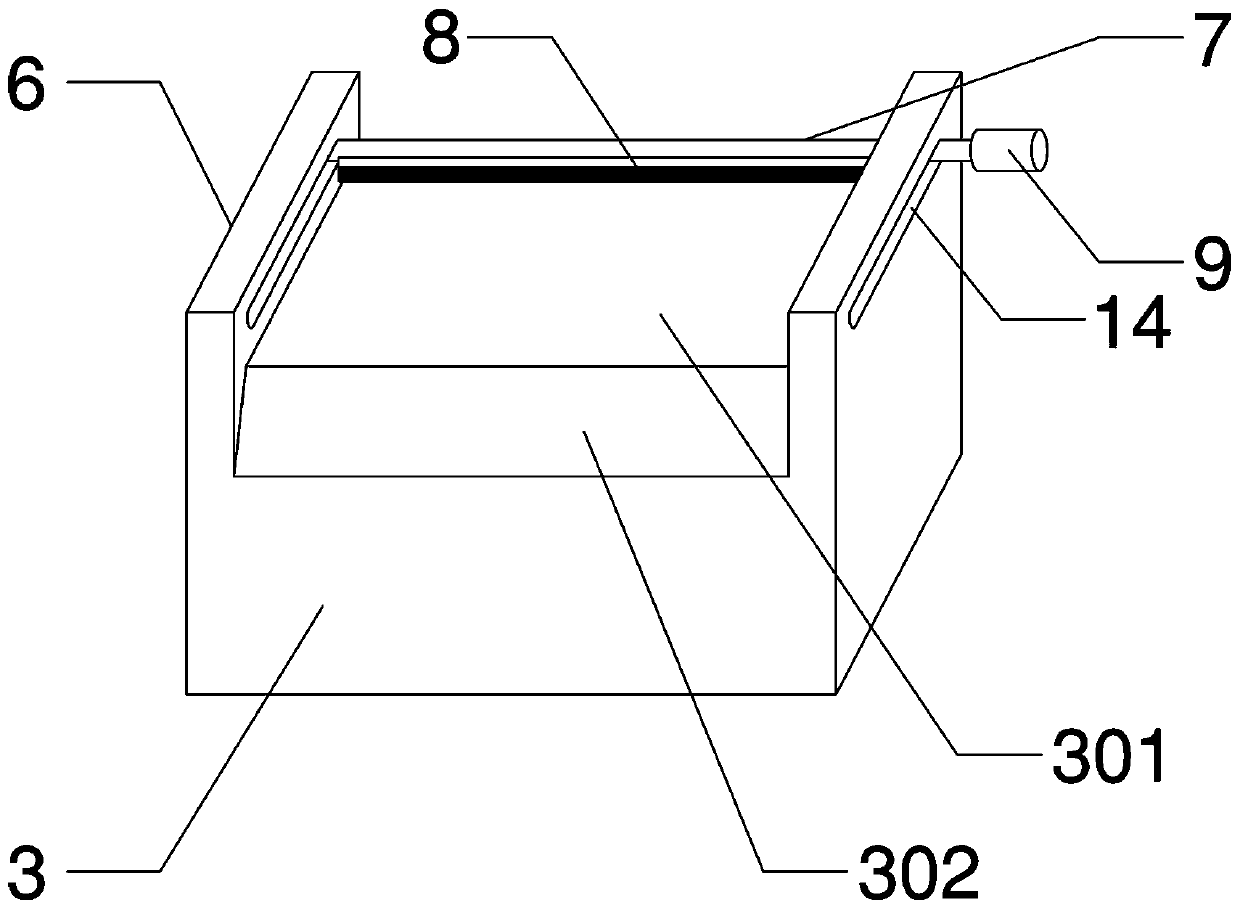

[0024] In a preferred solution, side ribs 6 are provided on both sides of the support plane 301 of the test block support platform 3, and chute 14 is provided on the side ribs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com