Dual-spindle type honing machine spindle reciprocating device

A technology of reciprocating motion and honing machine, which is applied in the direction of grinding drive device, honing machine tool, grinding feed motion, etc., can solve the problems of difficult to cooperate with processing, unable to work together, difficult to apply to the technical field of production line, etc., to improve production. Efficiency, lower production cost, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

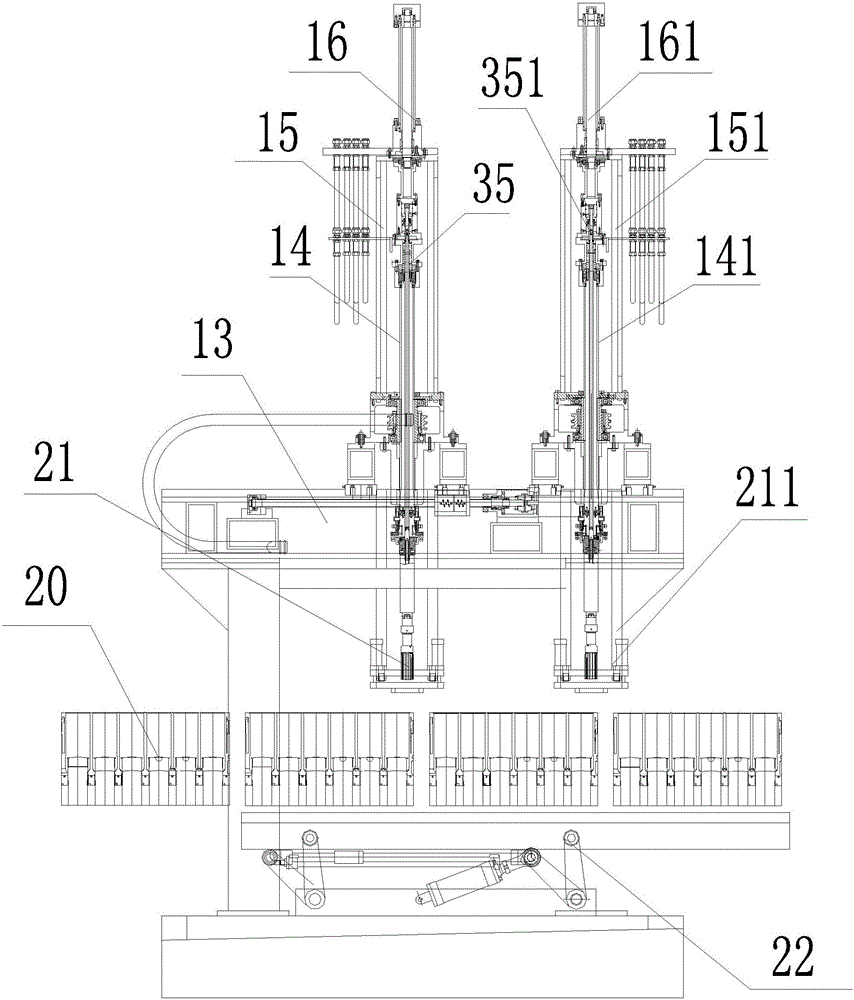

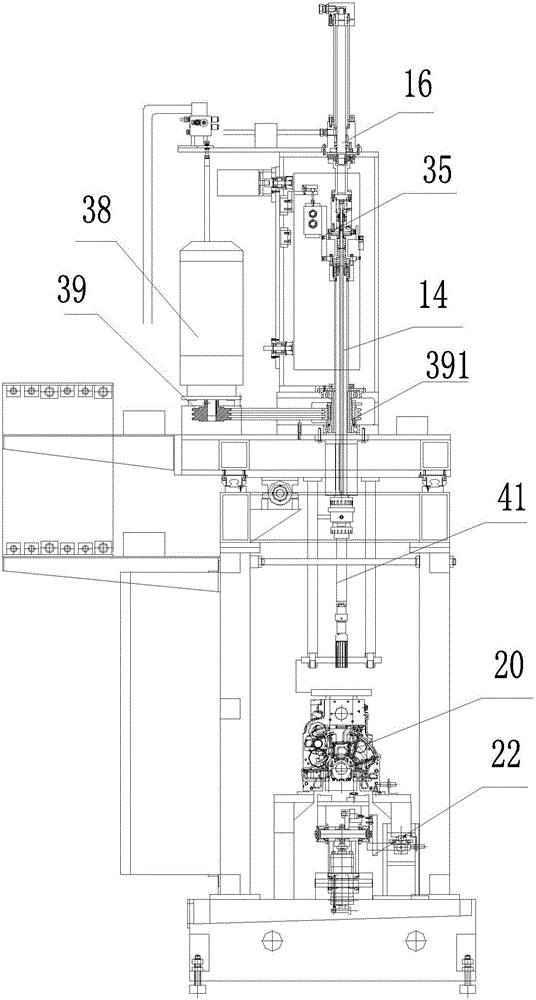

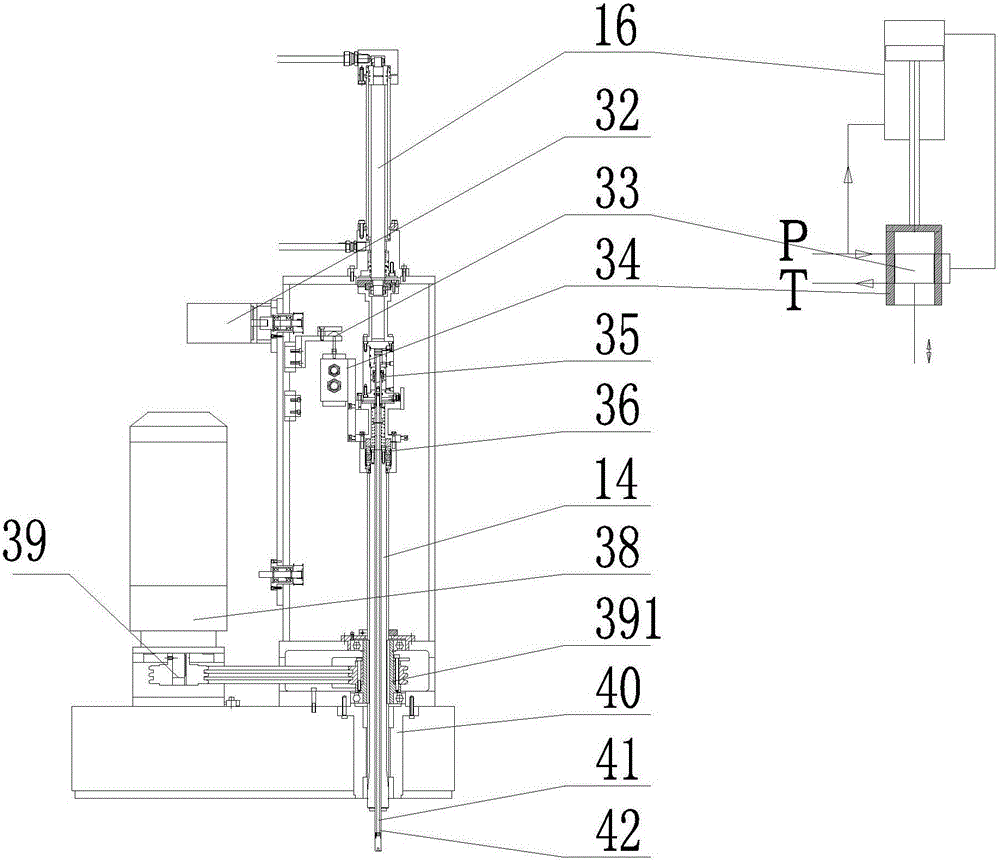

[0034] see Figure 1-2 As shown, the main shaft reciprocating motion device of the two-axis honing machine according to the embodiment of the present invention includes two main shafts, the upper ends of the two main shafts are respectively provided with double-feed oil cylinders, and the upper ends of the double-feed oil cylinders are provided with main reciprocating oil cylinders. Under the control of the numerical control system, the two main shafts are respectively driven to reciprocate; the two main shafts respectively drive the honing rod and the honing head to complete rough honing or fine honing of the workpiece 20 .

[0035] In the embodiment of the present invention, the main shaft reciprocating device of the two-axis honing machine includes a first main reciprocating oil cylinder 16, the piston rod of the main reciprocating oil cylinder 16 is connected with a first double-feed oil cylinder 35, and the piston of the first double-feed oil cylinder 35 The rod is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com